Annealing process for improving performance of 410 stainless steel

An annealing process and stainless steel technology, applied in the field of annealing process, can solve the problems of complex structure and no unified conclusion on strengthening mechanism.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

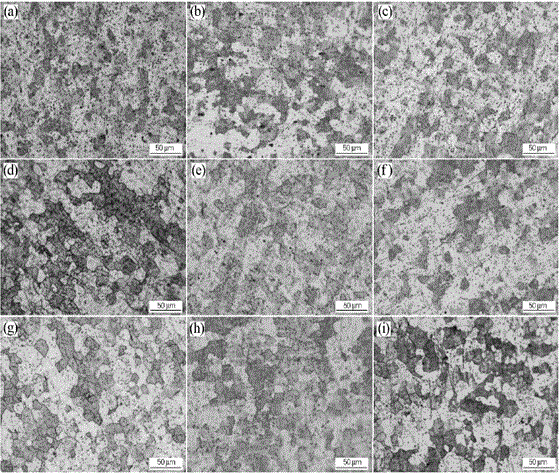

[0015] Table 1 shows the chemical composition of the 410 ferritic stainless steel cold-rolled plate used in the test analyzed by the mobile spectrometer PMI-MASTERPRO. The hot rolling finish temperature of this cold-rolled sheet was 850° C., and after annealing, it was cold-rolled to a final thickness of 0.8 mm.

[0016]

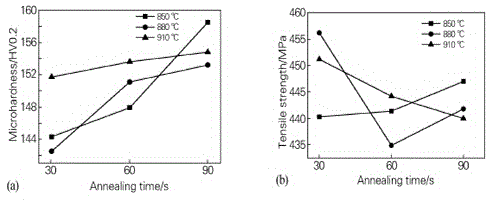

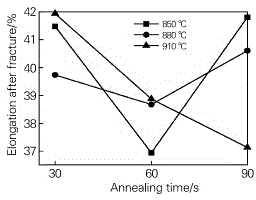

[0017] Since ferritic stainless steels maintain a body-centered cubic ferrite structure during heating and cooling, they cannot be strengthened by heat treatment. The dominant heat treatment of ferritic stainless steel is annealing to provide stress relief and recrystallization structure of banded structure caused by cold rolling, so as to ensure that the steel has good comprehensive properties of mechanical properties, cold formability and corrosion resistance. For the final annealing of 430 ferritic stainless steel cold-rolled sheets, the selection of the optimal annealing temperature is based on the principle that the grains do not grow too much and co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com