A kind of IF steel and preparation method thereof

A chemical composition, rough rolling technology, applied in the field of metal material processing, can solve the problems of low r value and high yield strength of IF steel, and achieve the effect of high r value and low yield strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

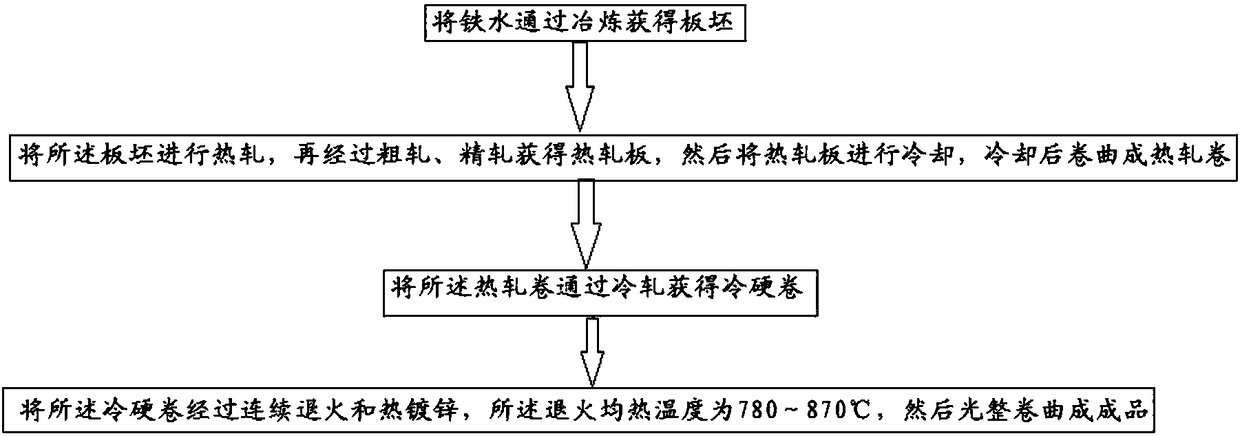

[0018] Based on the same inventive concept, the present invention also provides a kind of preparation method of IF steel, and described preparation method comprises the following steps:

[0019] Step 1, the molten iron is smelted to obtain a slab.

[0020] In step 2, the slab is hot-rolled, and then subjected to rough rolling and finish rolling to obtain a hot-rolled sheet, and then the hot-rolled sheet is cooled and curled into a hot-rolled coil after cooling.

[0021] In step 3, the hot-rolled coil is cold-rolled to obtain a chilled coil.

[0022] Step 4, subjecting the chilled coil to continuous annealing and hot-dip galvanizing, the annealing soaking temperature is 780-870° C., and then skin-curling to form a finished product.

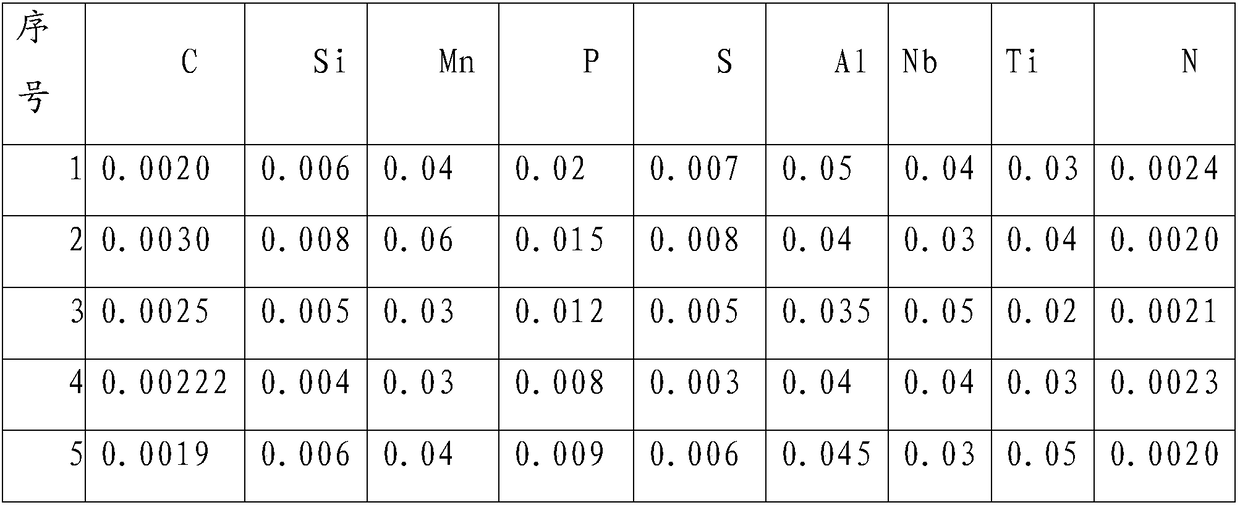

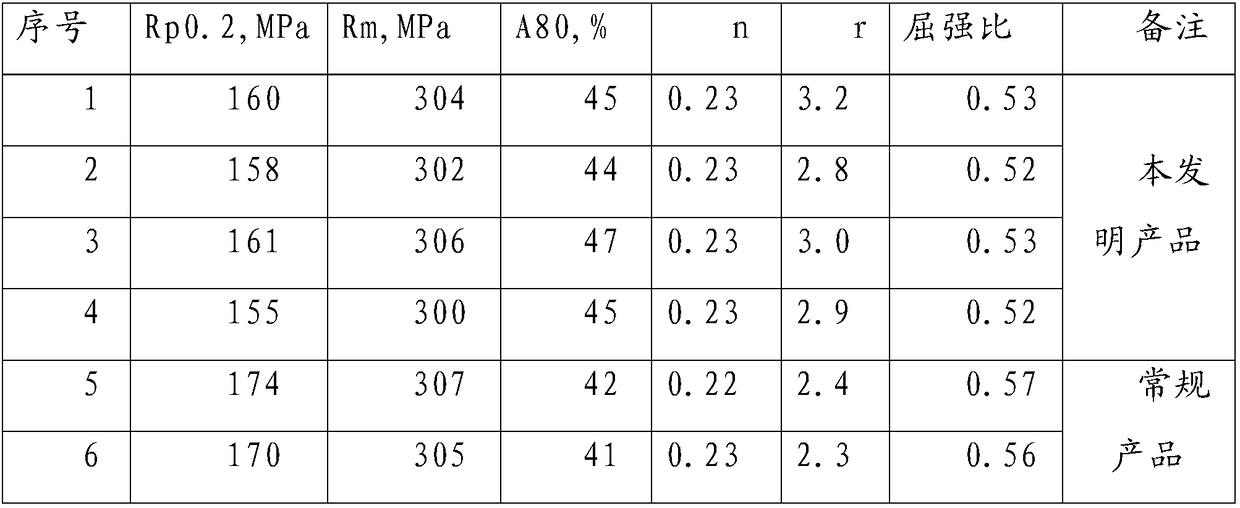

[0023] The technical solution of the present invention sets the chemical composition mass percentage of IF steel as follows: C: 0-0.0030%, Mn: 0.05-0.5%, Al: 0.01-0.08%, Nb: 0.01-0.06%, Ti: 0.01-0.06% , the limiting elements Si≤0.06%, P≤0.02%, S≤...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com