Steelpipe having high formability and method for production thereof

A manufacturing method and processability technology, applied in the direction of manufacturing tools, metal rolling, furnaces, etc., can solve the problems of r-value reduction and inapplicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

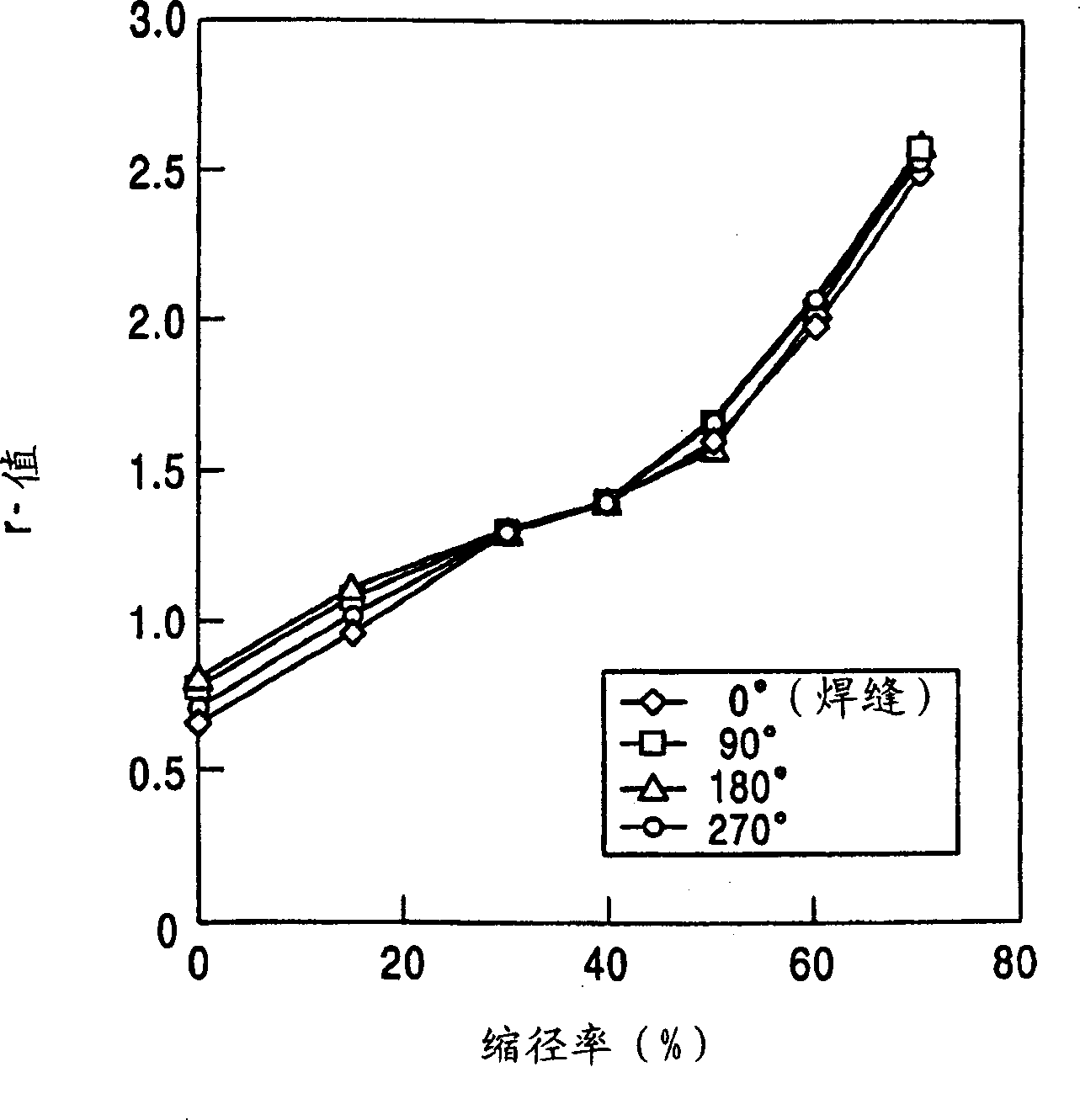

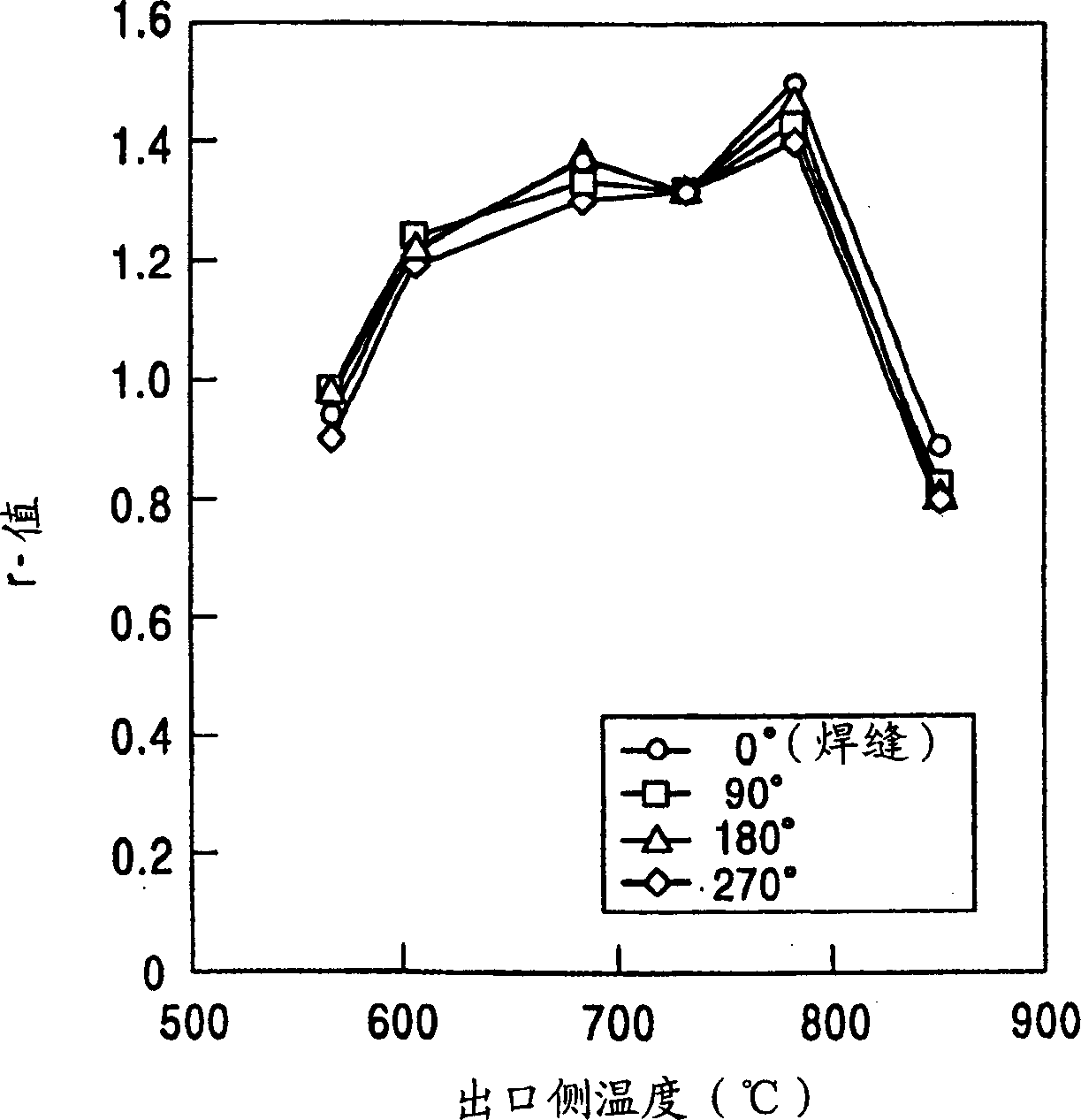

[0033] The hot-rolled steel sheets with the chemical compositions shown in Table 1 were made into electric-welded steel pipes by the usual method, and were reduced-rolled under the conditions shown in Table 2. After the heating before reducing rolling reached the temperature shown in Table 2, the heat preservation was not carried out, or the heat preservation was carried out for 1 to 600 seconds. Take the JIS No. 12 A tensile test piece from the circumferential position of the obtained steel pipe at 0°, 90°, 180°, and 270°, attach a strain gauge with a punctuation distance of 2mm on it, and perform a nominal strain of 6 to 7 % tensile test, measure the value of the actual strain εW in the width direction relative to the actual strain εL in the length direction, and calculate the r value based on the slope ρ. which is,

[0034] ρ=ε L / ε W

[0035] r value = ρ / (-1-ρ)

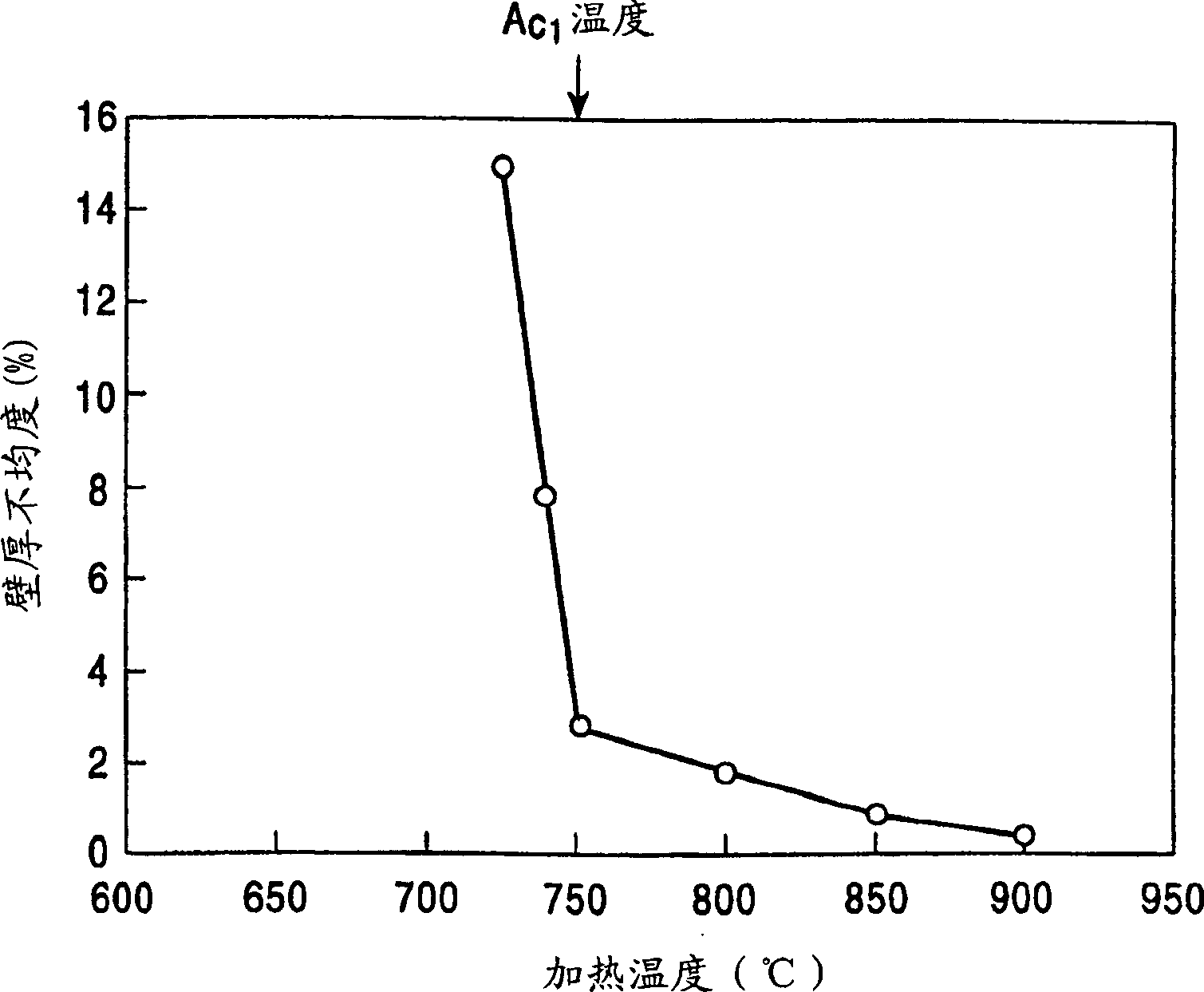

[0036] In addition, the wall thickness ts of the weld portion and the average wall thickness tb of other p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com