Positive electrode current collector and preparation method and application thereof

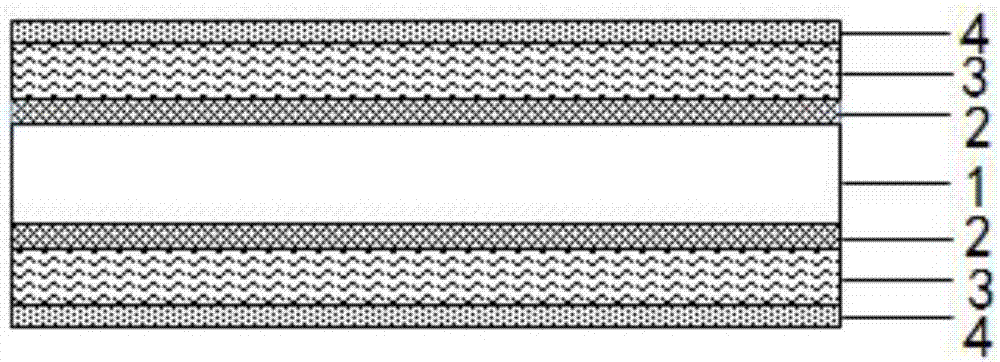

A technology of positive electrode current collector and plastic film, applied in the field of positive electrode current collector, can solve the problems of reducing the service life of lithium ion battery, falling off of aluminum coating, falling off of aluminum coating, etc. Easy to fall off effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for preparing a positive current collector, comprising the steps of:

[0037] S1. First, corona treatment is performed on the surface of the plastic film to be coated, and then the reel plastic film is placed in the vacuum chamber of the double-sided reciprocating electron beam evaporation coating machine, the vacuum chamber is sealed, and the vacuum is gradually evacuated until the vacuum degree reaches 3×10 -3 -6×10 -3 Pa, using electron gun to accelerate electron bombardment collision evaporation raw material Al 2 O 3 , adjust the unwinding speed, winding speed and evaporation, Al 2 O 3 Absorb heat and vaporize, forming a layer of Al on the surface of the moving film 2 O 3 Plating layer, that is, the adhesion enhancing layer;

[0038] S2. Al plating obtained in S1 2 O 3The film is placed in the vacuum chamber of the double-sided reciprocating evaporation coating machine, the vacuum chamber is sealed, and the vacuum is vacuumed step by step until the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com