Laser cladding method

A laser cladding and cladding technology, which is applied in the coating, metal material coating process, etc., can solve the problems of scrapped conveying pipes, poor working conditions, and falling off of electroplating layers, achieving fast cladding speed, The effect of small heat-affected zone and easy quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below with reference to the accompanying drawings and examples.

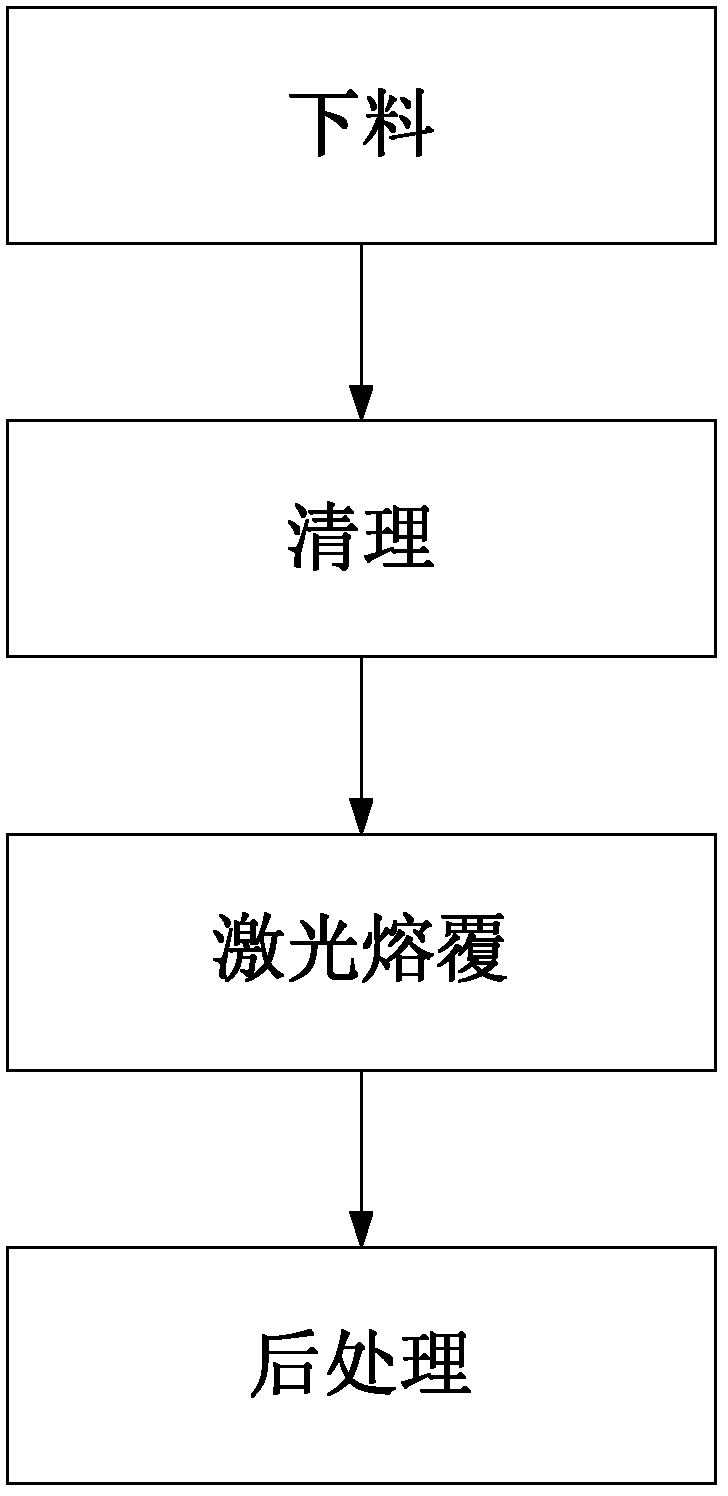

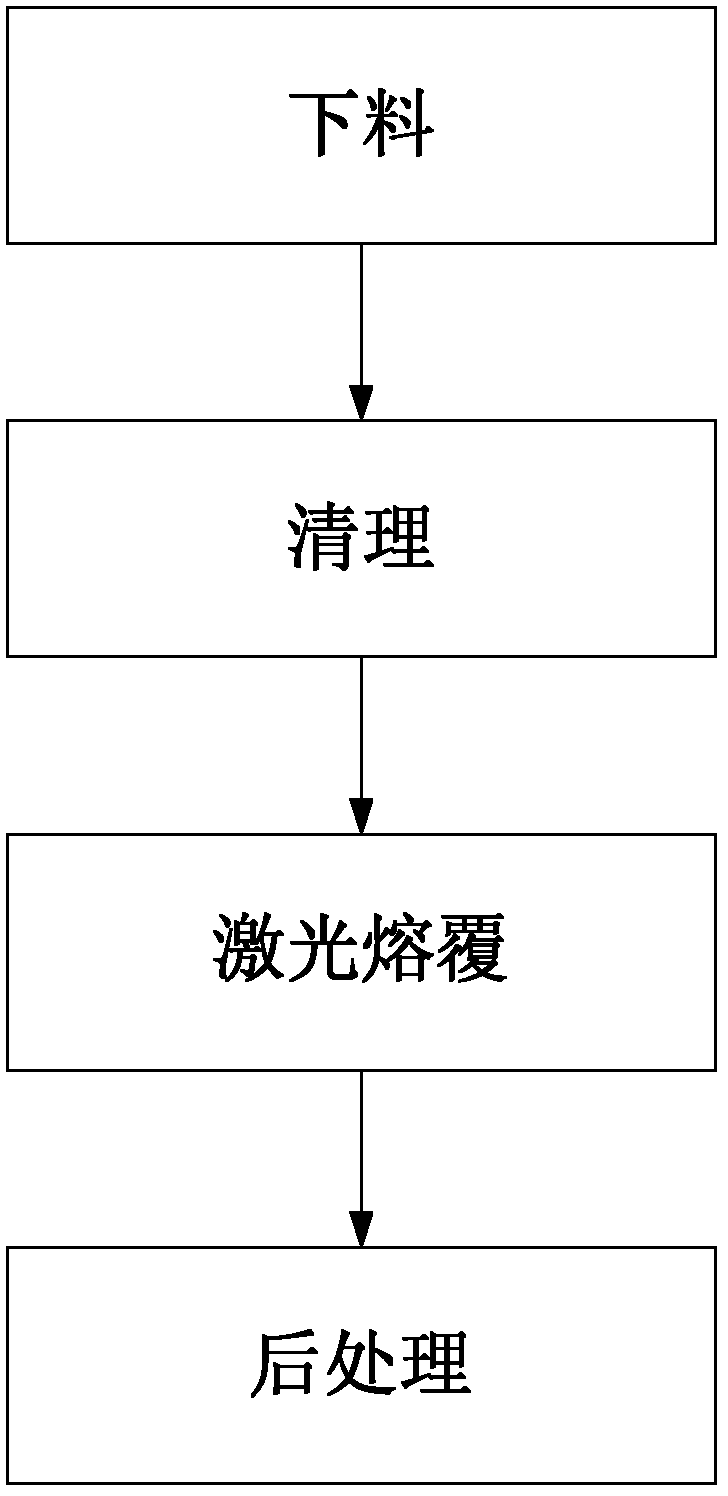

[0023] According to the laser cladding method of the present invention, it includes the following steps: blanking, preparing cladding materials for laser cladding according to the workpiece to be clad; It is fused with the parent material to form a cladding layer on the parent material; among them, the laser process parameters used in the laser cladding process include: laser power P, 1500W≤P≤10000W; laser scanning speed V, 600mm / min≤V≤3000mm / min; spot size, where the spot length is L, the spot width is W, 4mm≤L≤12mm, 1mm≤W≤8mm; the overlap rate J, 30%≤J≤70%.

[0024] The laser cladding method of the present invention will be described below by taking the laser cladding of shaft parts as an example:

[0025] Blanking step: making the raw material of the base material before laser cladding, which can be a semi-finished product, and the thickness of the pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com