Method for preparing modified urethane elastomer

A polyurethane elastomer and polyurethane material technology, applied in the field of materials, can solve the problems of reduced elongation at break, reduced elongation at break of composite materials, poor dispersion of carbon nanotubes, etc. The effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: Preparation of polyethylene glycol (molecular weight 2000) PEG-2000 modified single-wall carbon nanotube (SWNT-PEG2000) modified polyurethane elastomer:

[0033] (1) Take 1.0g of single-walled carbon nanotubes prepared by CVD (produced by Chengdu Organic Chemistry Co., Ltd., Chinese Academy of Sciences, diameter 1-2nm, purity ≥ 90%), add 300ml ratio of 3 / 1 concentrated sulfuric acid / concentrated nitric acid mixed acid In the solution, react under 100kHz ultrasonic wave for half an hour, heat to 40° C. and reflux for 4 hours. Then wash repeatedly with water until pH=7. The product was obtained by vacuum drying. Then mix it with the acidified product in 300ml of sulfuric acid / hydrogen peroxide mixture (ratio 2 / 1), ultrasonicate at 100kHz for half an hour, and heat to reflux at 70°C for 2 hours. Then wash repeatedly with water until pH=7. The product was vacuum-dried and collected for future use.

[0034](2) Take 500 mg of the above-mentioned acidified ca...

Embodiment 2

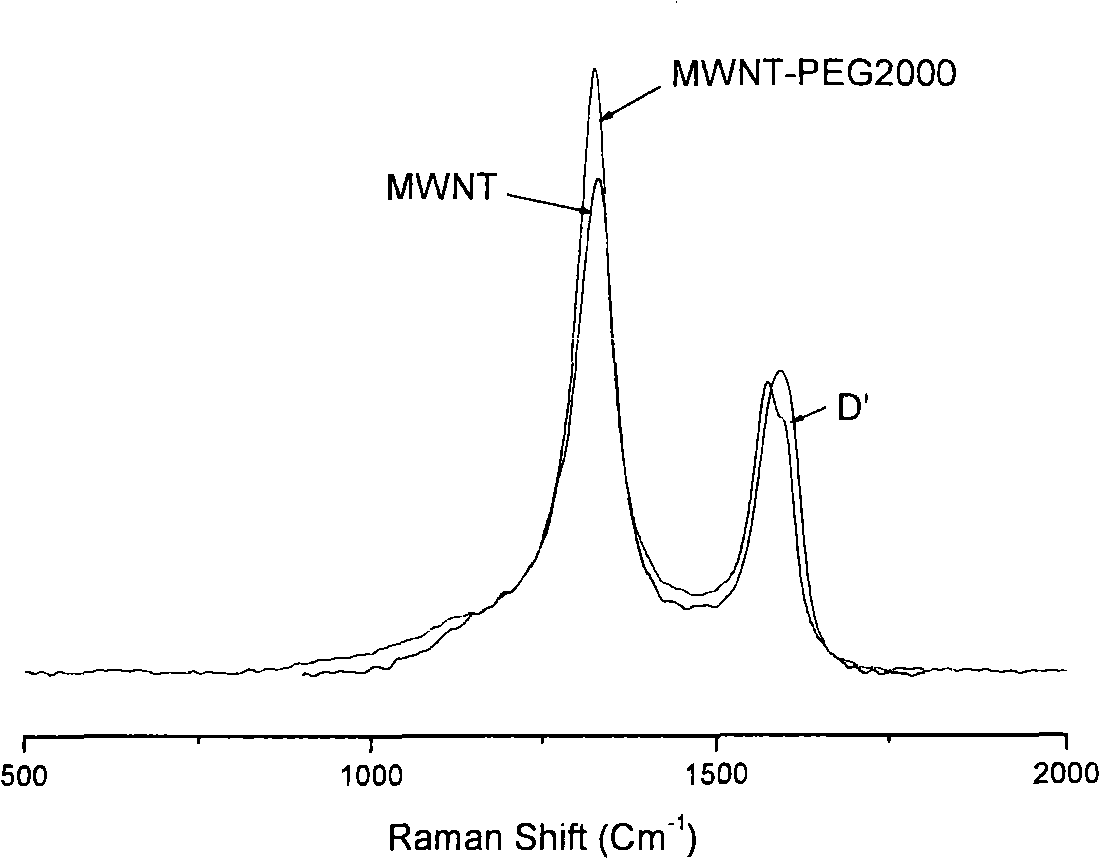

[0038] Embodiment 2: Preparation of polyethylene glycol (molecular weight 800) PEG-800 modified multi-walled carbon nanotubes (MWNT-PEG800) modified polyurethane elastomer

[0039] (1) Take 1.0 g of multi-walled carbon nanotubes prepared by CVD (produced by Chengdu Organic Chemistry Co., Ltd., Chinese Academy of Sciences, with a diameter of 8 to 15 nm and a purity of ≥90%), and add 300 ml of mixed acid with a ratio of 3 / 1 concentrated sulfuric acid / concentrated nitric acid In the solution, react under 100kHz ultrasonic wave for half an hour, heat to 40° C. and reflux for 4 hours. Then wash repeatedly with water until pH=7. The product was obtained by vacuum drying. Then mix it with the acidified product in 300ml of sulfuric acid / hydrogen peroxide mixture (ratio 2 / 1), ultrasonicate at 100kHz for half an hour, and heat to reflux at 70°C for 2 hours. Then wash repeatedly with water until pH=7. The product was vacuum-dried and collected for future use.

[0040] (2) Take 500 mg...

Embodiment 3

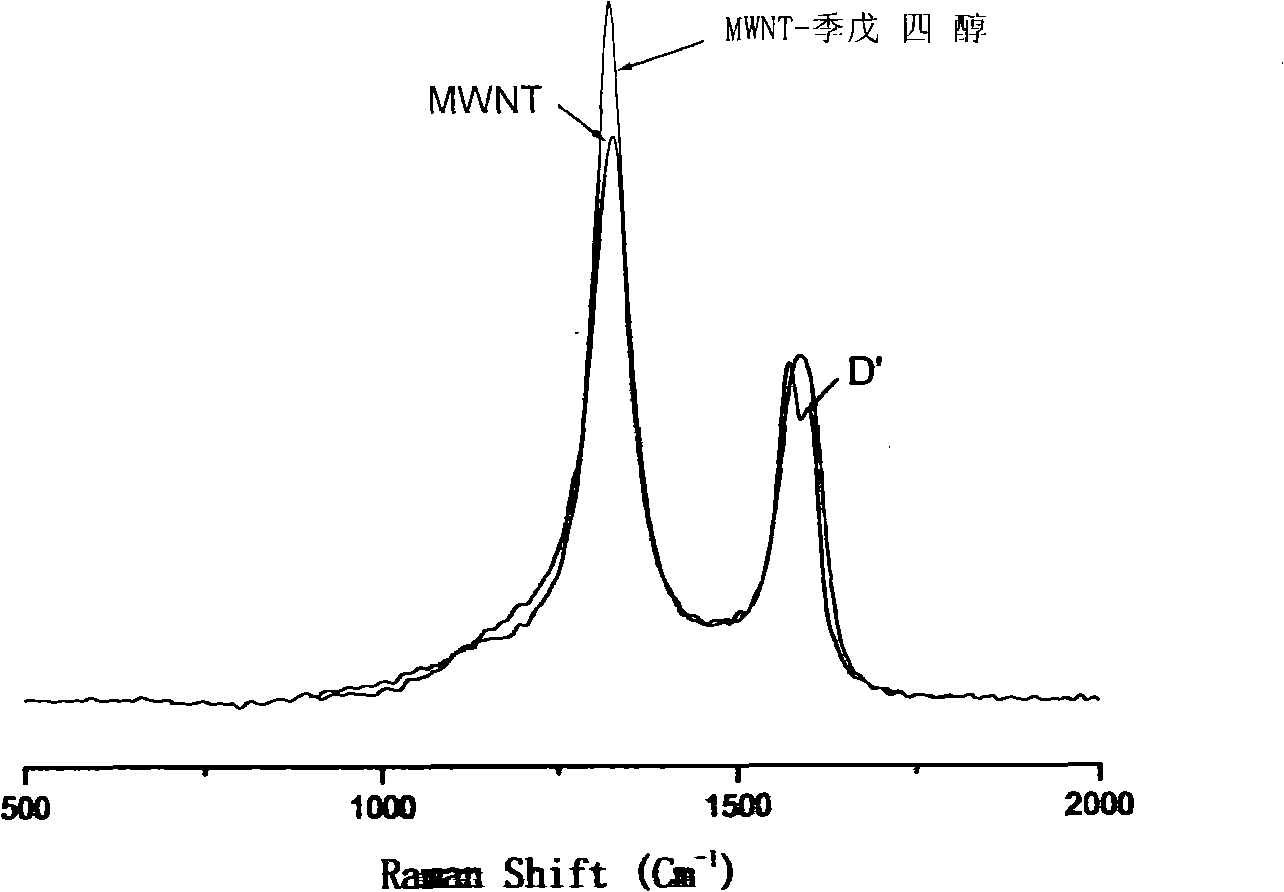

[0045] Embodiment 3: Preparation of pentaerythritol modified single-walled carbon nanotube (SWNT-PE) modified polyurethane elastomer

[0046] (1) Take 1.0g of single-walled carbon nanotubes prepared by CVD (produced by Chengdu Organic Chemistry Co., Ltd., Chinese Academy of Sciences, diameter 1-2nm, purity ≥ 90%), add 300ml ratio of 3 / 1 concentrated sulfuric acid / concentrated nitric acid mixed acid In the solution, react under 100kHz ultrasonic wave for half an hour, heat to 40° C. and reflux for 4 hours. Then wash repeatedly with water until pH=7. The product was obtained by vacuum drying. Then mix it with the acidified product in 300ml of sulfuric acid / hydrogen peroxide mixture (ratio 2 / 1), ultrasonicate at 100kHz for half an hour, and heat to reflux at 70°C for 2 hours. Then wash repeatedly with water until pH=7. The product was vacuum-dried and collected for future use.

[0047] (2) Take 500 mg of the above-mentioned acidified single-walled carbon nanotubes and 10 g of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com