Movable hopper type powder bed powder laying device and method

A technology of moving hoppers and powder spreading devices, which is applied in the directions of transportation, packaging, loading/unloading, etc. It can solve the problems of increasing the probability of raw material bonding, affecting processing efficiency, and the same amount of blanking, so as to reduce the probability of bonding , reduce time and process, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

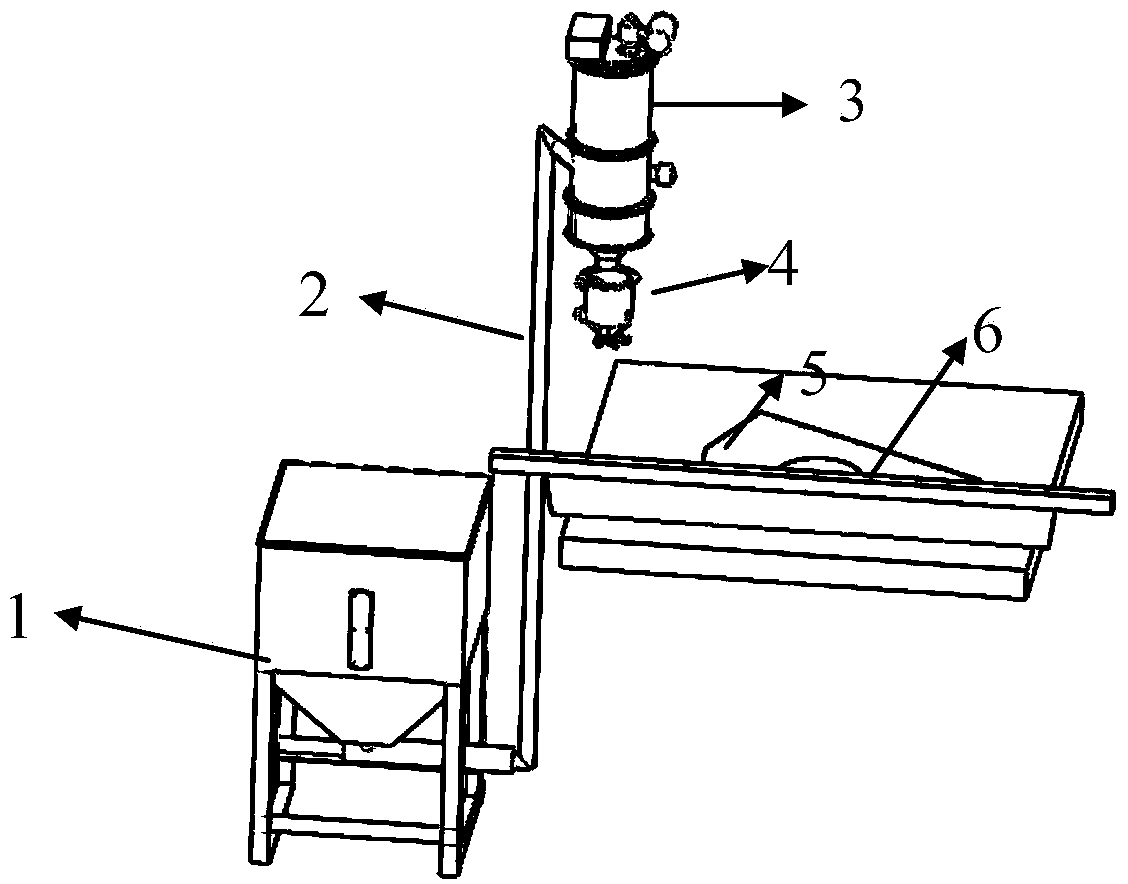

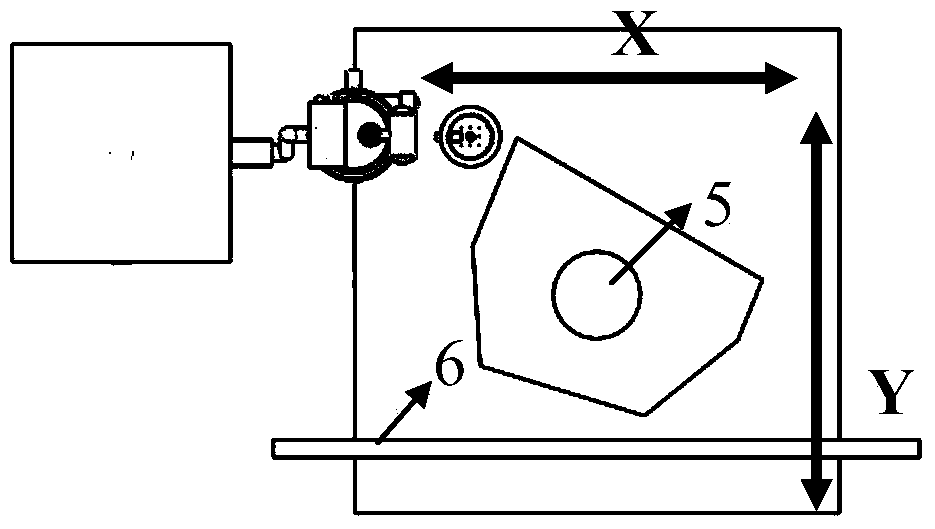

[0034] The specific embodiments of the present invention are described in detail in conjunction with the technical scheme and accompanying drawings, and the present invention is further described.

[0035] This embodiment is described in conjunction with rapid prototyping equipment, and the protection of the present invention is not limited thereto.

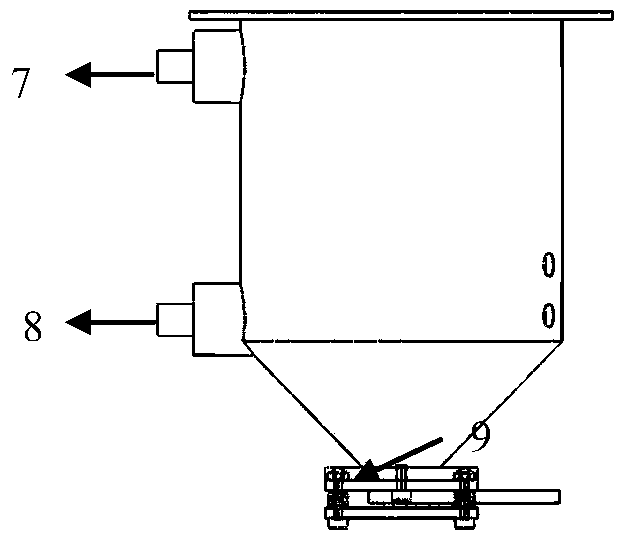

[0036] 1. Before the rapid prototyping equipment runs, the volume value of each layer of powder is determined by the CAD graphics of the parts, the cross-sectional area of the processed and formed cylinder, and the layer thickness. It is used to guide the position of the material level sensor in the hopper, control the movement speed of the moving hopper and the opening and closing degree of the outlet at the bottom of the hopper. Adjust the height of the upper and lower material level sensors in the hopper so that the volume of the part below the lower material level sensor is greater than or equal to the demand for single-lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com