Liquid permeability clad sheet, manufacturing device thereof and manufacturing method thereof

A technology for composite sheets and manufacturing equipment, applied in medical science, bandages, etc., can solve problems such as hindering liquid penetration, achieve the effects of reducing contact area, improving utilization rate, and reducing sticky feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation of the liquid-permeable composite sheet of the present invention and its manufacturing equipment and manufacturing method will be described in detail below with reference to the accompanying drawings.

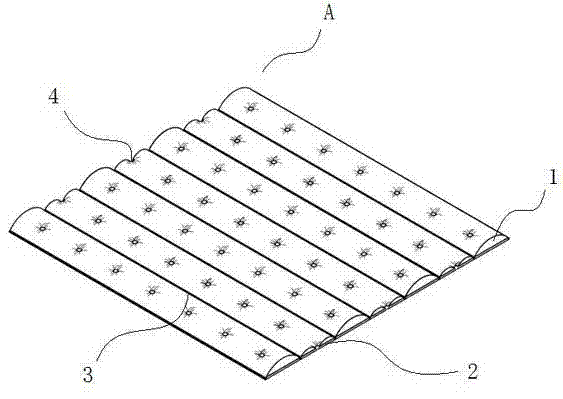

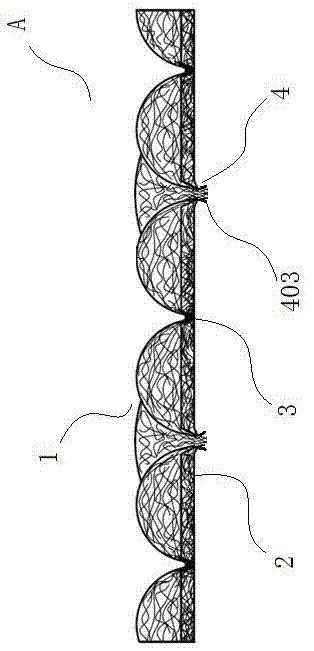

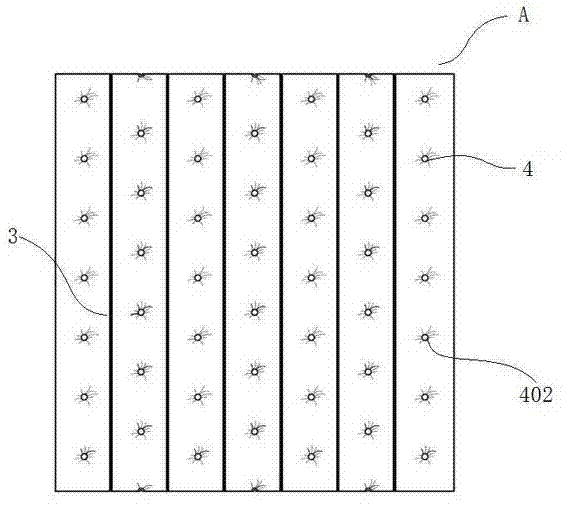

[0026] figure 1 It is a perspective view of Example 1 of the liquid-permeable composite sheet A of the present invention, figure 2 It is a vertical section view of Example 1 of the liquid-permeable composite sheet A of the present invention. Such as figure 1 and figure 2 As shown, the liquid-permeable composite sheet A of the disposable bodily fluid-absorbing hygienic article of this embodiment is composed of at least two sheets: an upper first layer sheet 1 and a lower second layer sheet 2 . The first sheet 1 and the second sheet 2 are both liquid-permeable flexible sheets, and non-woven fabrics, textiles, perforated films, microporous films, fiber aggregates, and liquid-permeable composite sheets can be selected. Made of flexible mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com