Crucible and coating method thereof

A crucible and coating technology, applied to the crucible for producing silicon material, and applied in the field of coating on this crucible, can solve the problems of leakage, unsatisfactory demoulding effect, increase of silicon material, etc., and achieve uniform heat conduction and excellent thermal conductivity. , the effect of improving internal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

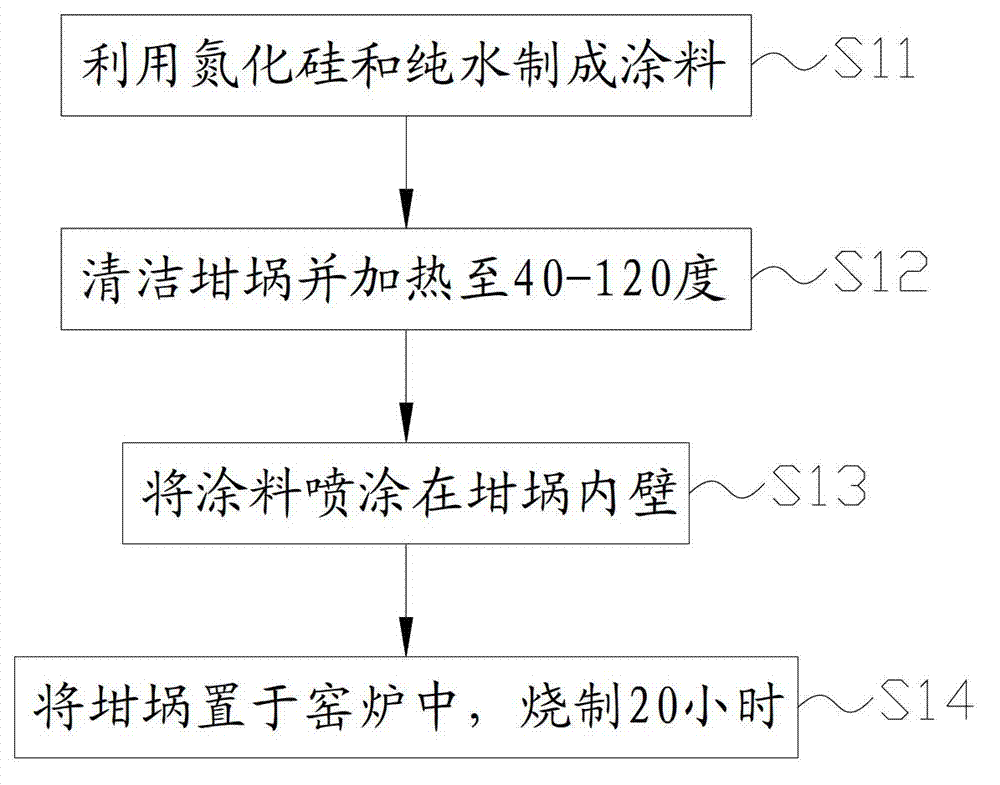

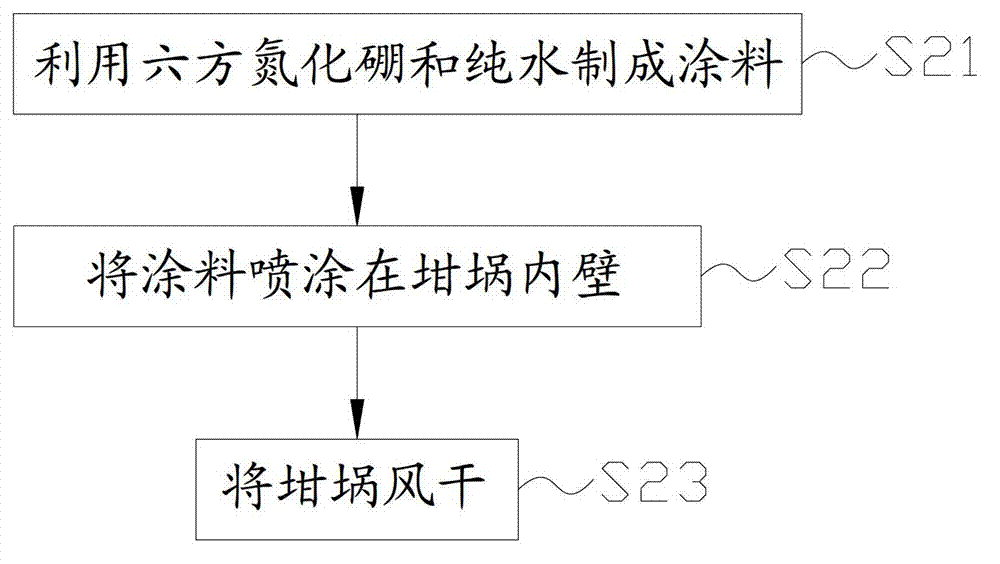

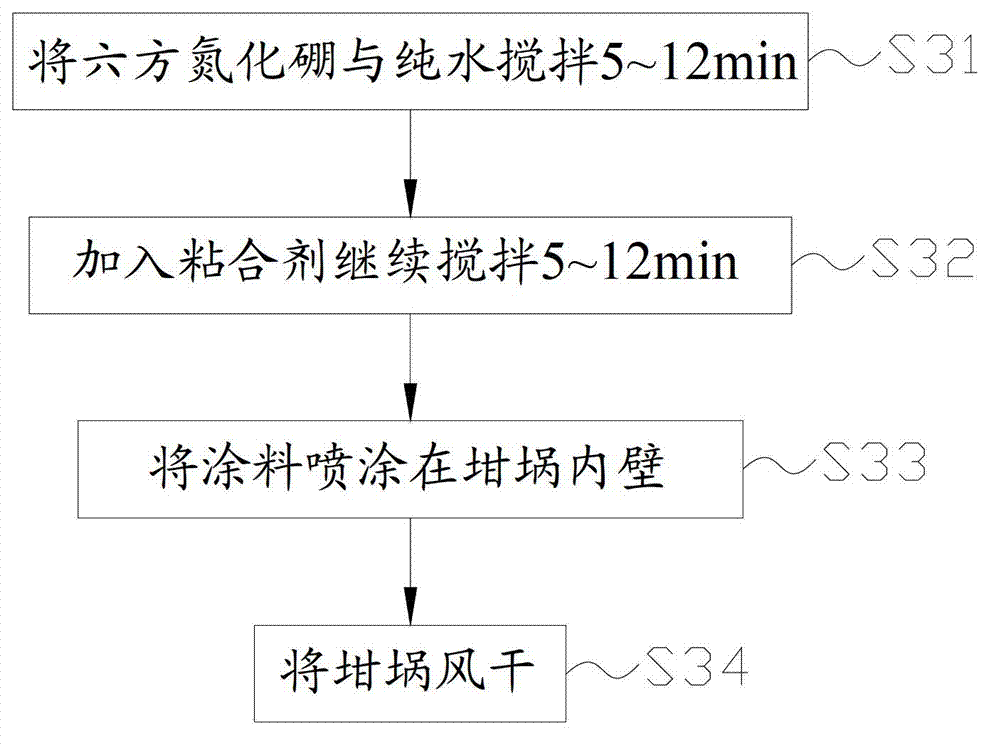

[0034] The core of the present invention is to provide a crucible coating method, which can effectively improve the coating efficiency of the crucible and reduce the possibility of reaction between the crucible and silicon material. Another core of the present invention is to provide a crucible manufactured by the above-mentioned coating method, which can effectively improve the production efficiency and production quality of silicon blocks.

[0035] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0036] It should be noted that the present invention is mainly applied in the field of preparing monocrystalline silicon / polycrystalline silicon, and the following uses casting polycrystalline silicon ingots as an example for introduction.

[0037] In addition, two terms will be mentioned in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com