Spiral multi-section combined type sealing labyrinth

A grate-tight, helical-type technology, applied in the machine/engine, leakage prevention, mechanical equipment and other directions, can solve the problems of reducing the transition state performance of the whole machine, reducing the stability margin of the compression system, etc., and achieve great military application value, The effect of increasing the combat radius and increasing security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings.

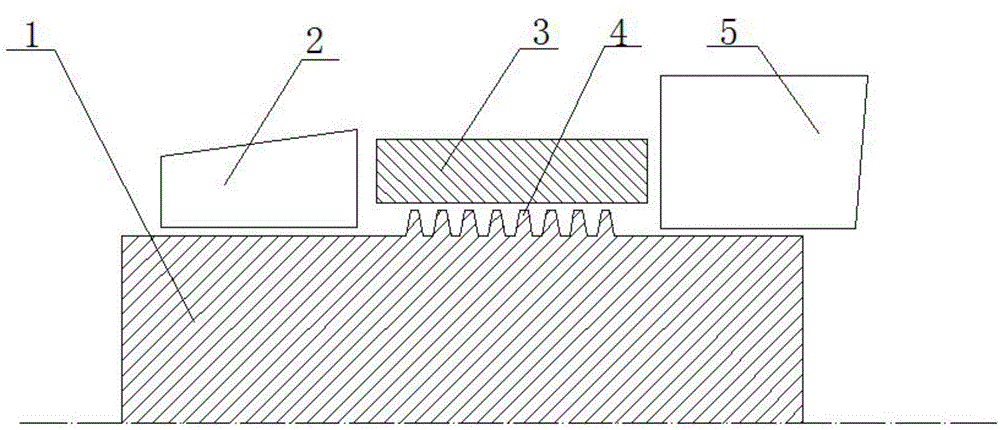

[0016] in figure 1 It is a schematic diagram of the traditional sealing grate structure. The rotating shaft 1 is processed with ordinary grate teeth 4, which together with the stationary ring surface 3 form a sealing surface to isolate the high-pressure air chamber 2 and the lubricating oil chamber 5.

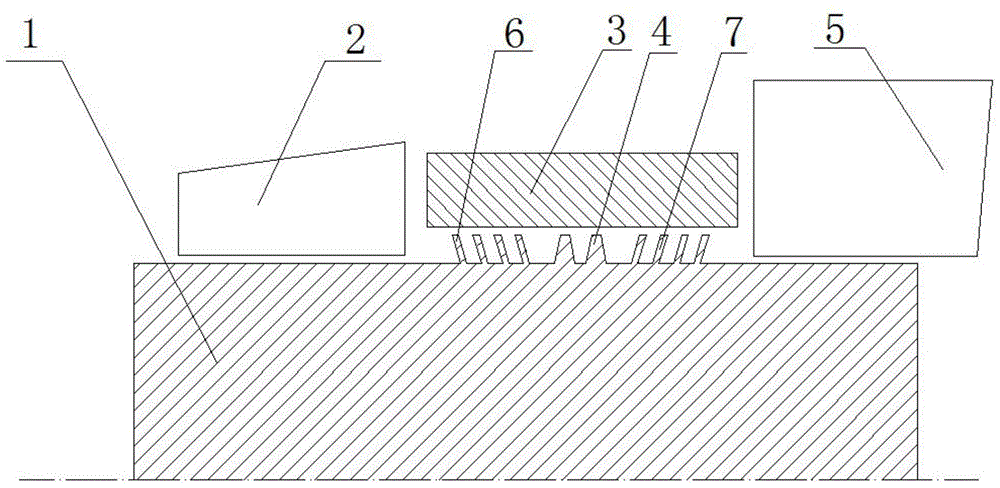

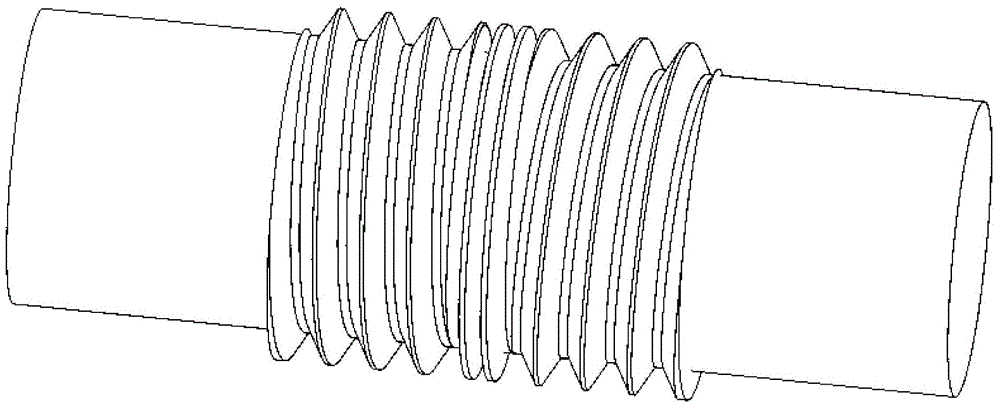

[0017] Such as figure 2 As shown, the present invention provides a spiral multi-section combined sealing grate structure, which includes a rotating shaft 1 with a common grate 4 and a stationary ring surface 3, and the left and right sides of the common grate 4 are respectively provided with left sections The spiral grate teeth 6 and the right spiral grate teeth 7, the left spiral grate teeth 6 and the right spiral grate teeth 7 have opposite directions of rotation, and the stationary ring surface 3 is close to the left spiral grate Teeth 6, right section s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com