Constant-temperature and constant-humidity air treatment equipment provided with two stages of heat recovery devices

A heat recovery device and air treatment technology, used in lighting and heating equipment, shielding with air flow, energy recovery systems for ventilation and heating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

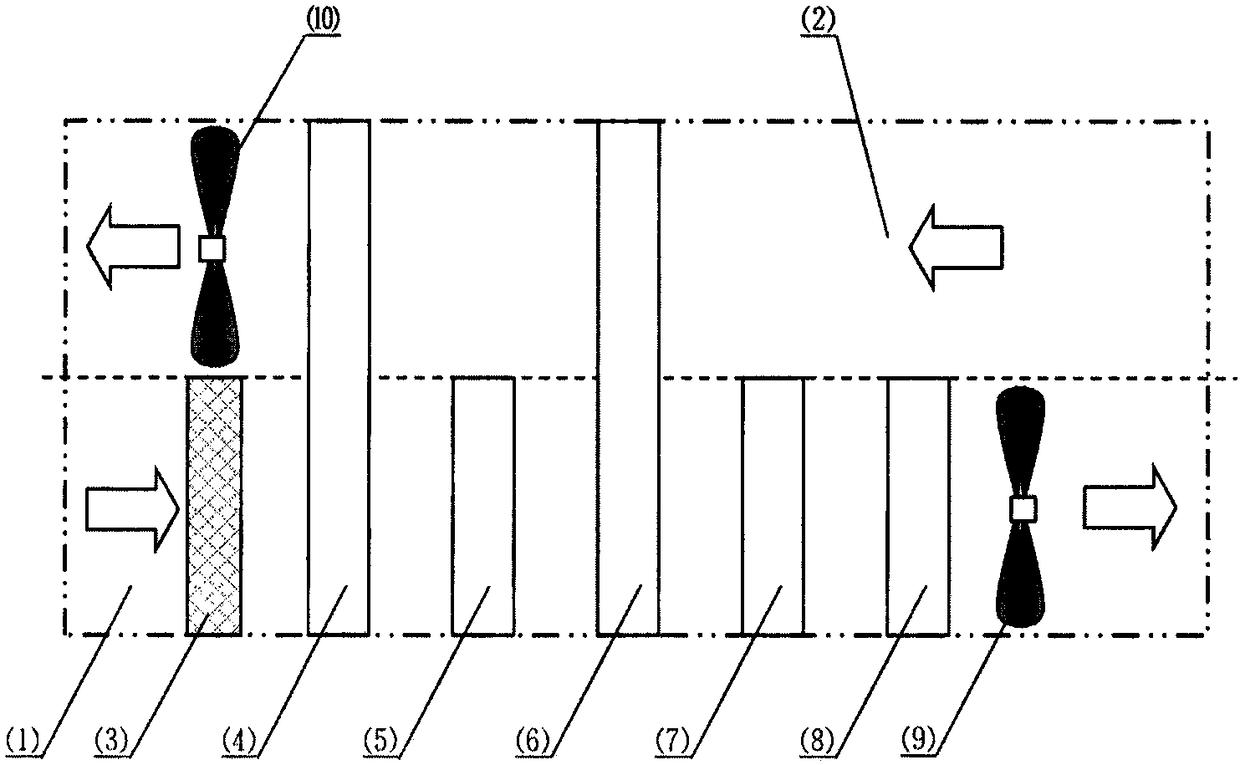

[0019] refer to figure 1 Describe the constant temperature and humidity air treatment equipment of the present invention, taking summer working conditions as an example:

[0020] The fresh air enters the fresh air air conditioning box (1) through the air inlet, and after the fresh air passes through the dust removal and filtering equipment (3) selected by the system, at this time, the fresh air enters the full-heated air-air heat exchanger (4) in a state of high temperature and high humidity, and The low-temperature and low-humidity exhaust air on the other side of the full-hot air-air heat exchanger (4) conducts heat and humidity transfer, thereby greatly reducing the temperature and humidity of the fresh air, and then enters the refrigeration coil (5) for deep cooling, Dehumidification until the moisture content of the outlet state reaches the moisture content of the air supply state point; in this state, the normal state is: although the humidity meets the air supply requi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com