Oil-cooled motor cooling system

A motor cooling and oil cooling technology, applied in the field of vehicles, can solve the problems of increasing the weight and cost of the gearbox, reducing the inlet temperature of the coolant, and the large volume of the water jacket, so as to avoid long-term accumulation, low inlet temperature and good cooling effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065]In order to make the purpose, technical solutions and advantages of the present application, the present application will be further described in connection with the accompanying drawings, which will be apparent from the following examples, and not all of the embodiments. Based on the embodiments in the present application, all other embodiments obtained without making creative labor have not made creative labor premises.

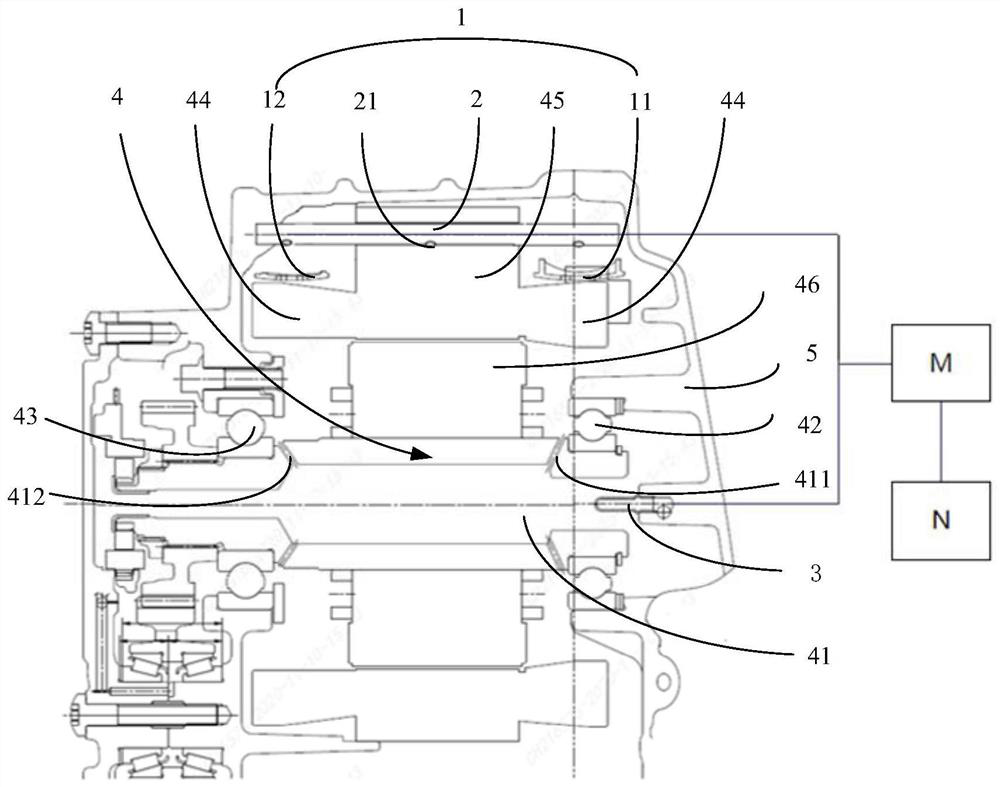

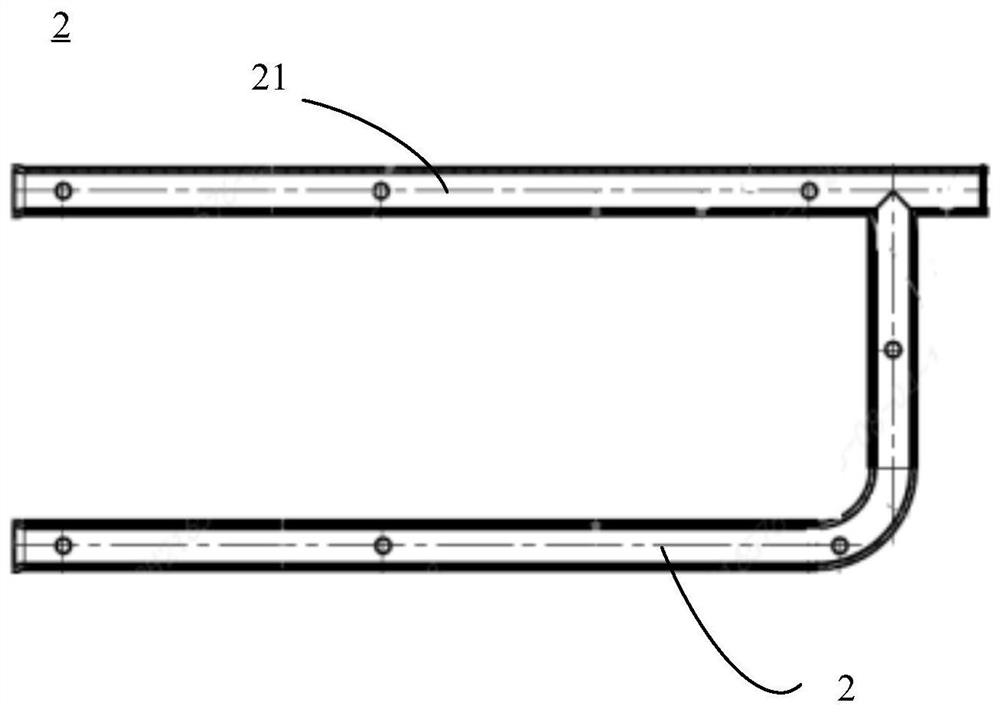

[0066]Such asfigure 1 As shown, the present application embodiment provides an oil-cooling motor cooling system including a gauge assembly 1, a fuel tube 2, a further oil tube 3, and a motor 4.

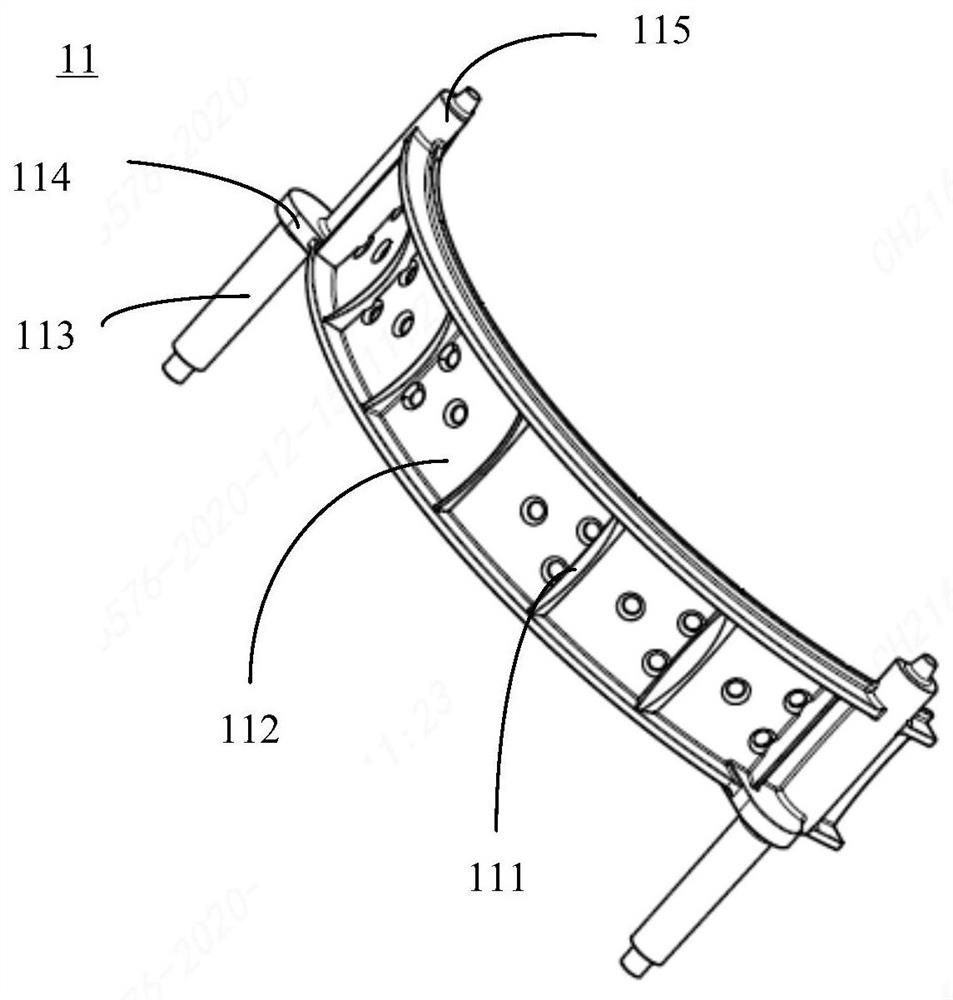

[0067]The motor 4 includes a rotor shaft 41 that supports a first bearing 42 and a second bearing 43 of the rotor shaft 41, a stator winding 44, a stator core 45, and a rotor core 46. It will be noted here that motor 4 can be a type of motor commonly seen in the art, so the positional relationship between the internal components and various components is well known to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com