Double-turbine boosting expansion machine propane dehydrogenation cold box separation system and technique

A turbocharger and expander technology, applied in the field of propane dehydrogenation cold box separation system, can solve the problems of the risk of liquid in the inlet of the expander, the low C3 recovery rate, and the difficulty of gas-liquid separation, etc., to eliminate Risk of liquid entrainment, reduced design difficulty, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

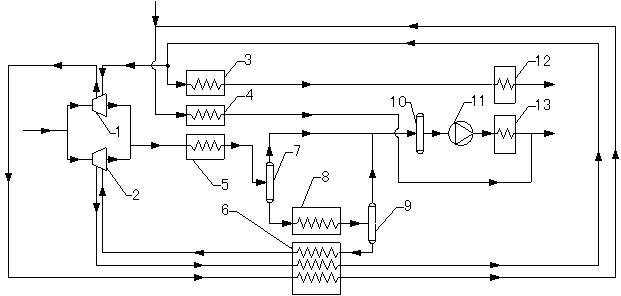

[0013] Such as figure 1 As shown, the double-turbine supercharged expander propane dehydrogenation cold box separation system includes a low pressure expander 1, a high pressure expander 2, a first cold mixed feed heat exchanger 3, a second cold mixed feed heat exchanger 4, The third cold mixed feed heat exchanger 5, the first expansion heat exchanger 6, the high temperature separator 7, the second expansion heat exchanger 8, the intermediate temperature separator 9, the flash tank 10, the liquid pump 11, the first feed Quench cooler 12, second feed quencher 13; after the low pressure expander 1, high pressure expander 2 are connected in parallel, they are connected to the inlet of the high temperature separator 7 through the third cold mixed feed heat exchanger 5. The gas of the high temperature separator 7 The outlet is connected to the inlet of the intermediate temperature separator 9 through the second expansion heat exchanger 8, the liquid outlet of the high temperature se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com