Separation and recycling device and recycling method for methane and argon in synthetic ammonia relief gas

A technology of degassing, separation and recovery of synthetic ammonia, which is applied in refrigeration and liquefaction, lighting and heating equipment, liquefaction, etc. It can solve the problems of energy waste and environmental pollution, and achieve the effect of easier energy matching, high purity and small consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

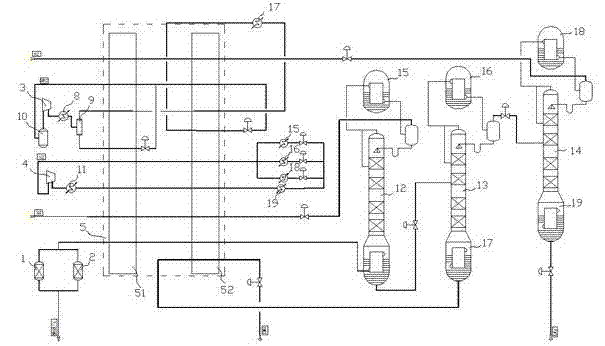

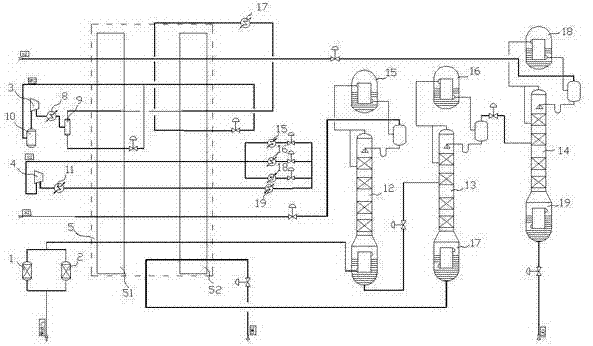

[0033] Separation and recovery device for methane and argon in the purge gas of synthetic ammonia, including cold box, raw gas pipeline, water cooler 8. Water cooler 11. Gas-liquid separator 9, gas-liquid balance tank 10, throttling and pressure reducing valve, purification system connected with raw gas pipeline, refrigeration system for cryogenic separation and step-by-step separation of purge gas The rectification system, the purification system includes the first molecular sieve adsorber 1 and the second molecular sieve adsorber 2, and the purification system is connected with the main heat exchanger 5 through pipelines. Refrigeration system includes mixed refrigerant cycle compressor 3, medium pressure cycle nitrogen compressor 4 and main heat exchanger 5, mixed refrigerant cycle compressor 3, water cooler 8. The gas-liquid separator 9, the gas-liquid balance tank 10 and the main heat exchanger 5 are connected through pipelines, and the medium-pressure circulating nitr...

Embodiment 2

[0038] The method for separating and recovering methane and argon using the device described in Example 1 may further comprise the steps:

[0039] Step a: After mixing the exhaust gas of synthetic ammonia, it passes through a purification system equipped with a first molecular sieve adsorber 1 and a second molecular sieve adsorber 2 to remove trace amounts of ammonia and CO 2 , moisture and other impurities;

[0040] Step b: use the purified purge gas in step a as feed gas into the main heat exchanger 5 for heat exchange, be cooled to a gas-liquid mixed state, and then exit the main heat exchanger 5 and enter the dehydrogenation tower 12, the dehydrogenation tower 12 Most of the hydrogen is separated, and the hydrogen-rich gas containing more hydrogen is throttled and decompressed, and then reheated by the main heat exchanger 5 to leave the cold box, and the hydrogen-poor liquid is obtained at the bottom of the dehydrogenation tower 12, which is sent into methane after throttl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com