System and method for monitoring operation energy efficiency ratio of water chilling unit

A chiller and monitoring system technology, which is applied in the direction of refrigerators, refrigeration components, heating and ventilation control systems, etc., can solve the problems of inappropriate selection of chillers, low energy efficiency ratio and rated energy efficiency ratio, and mismatch between chillers and auxiliary equipment and other issues, to achieve the effect of timely maintenance and waste reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

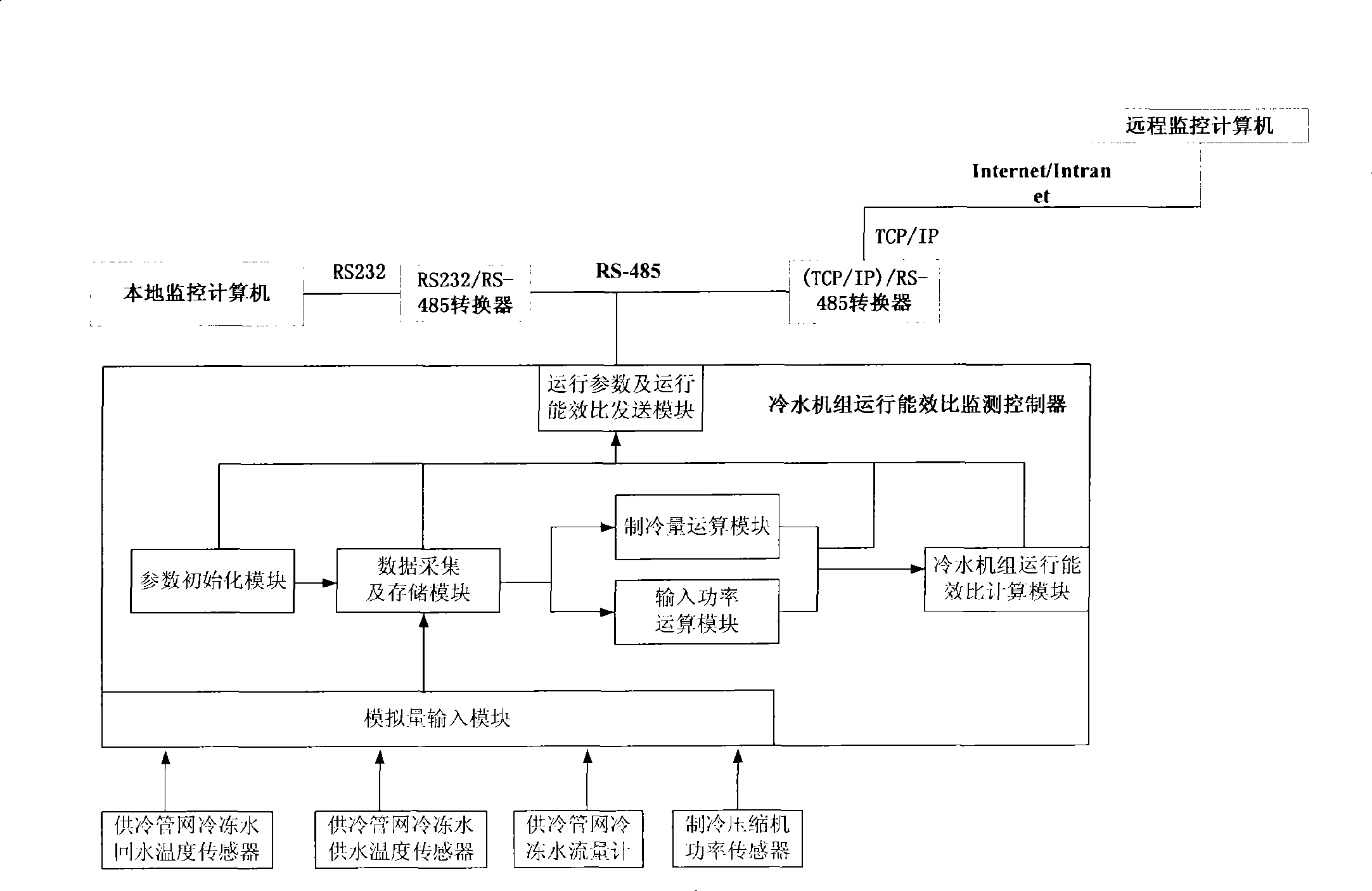

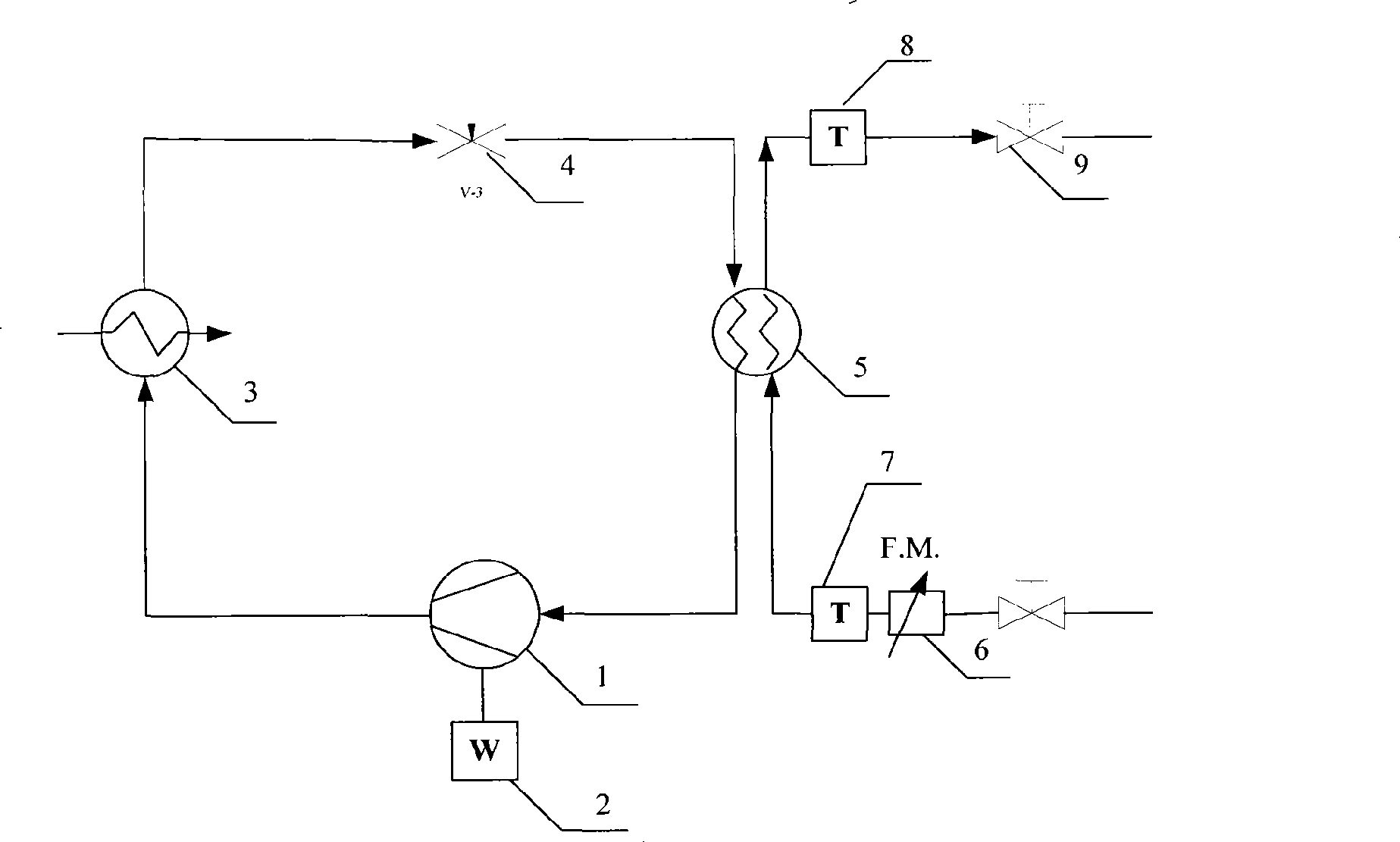

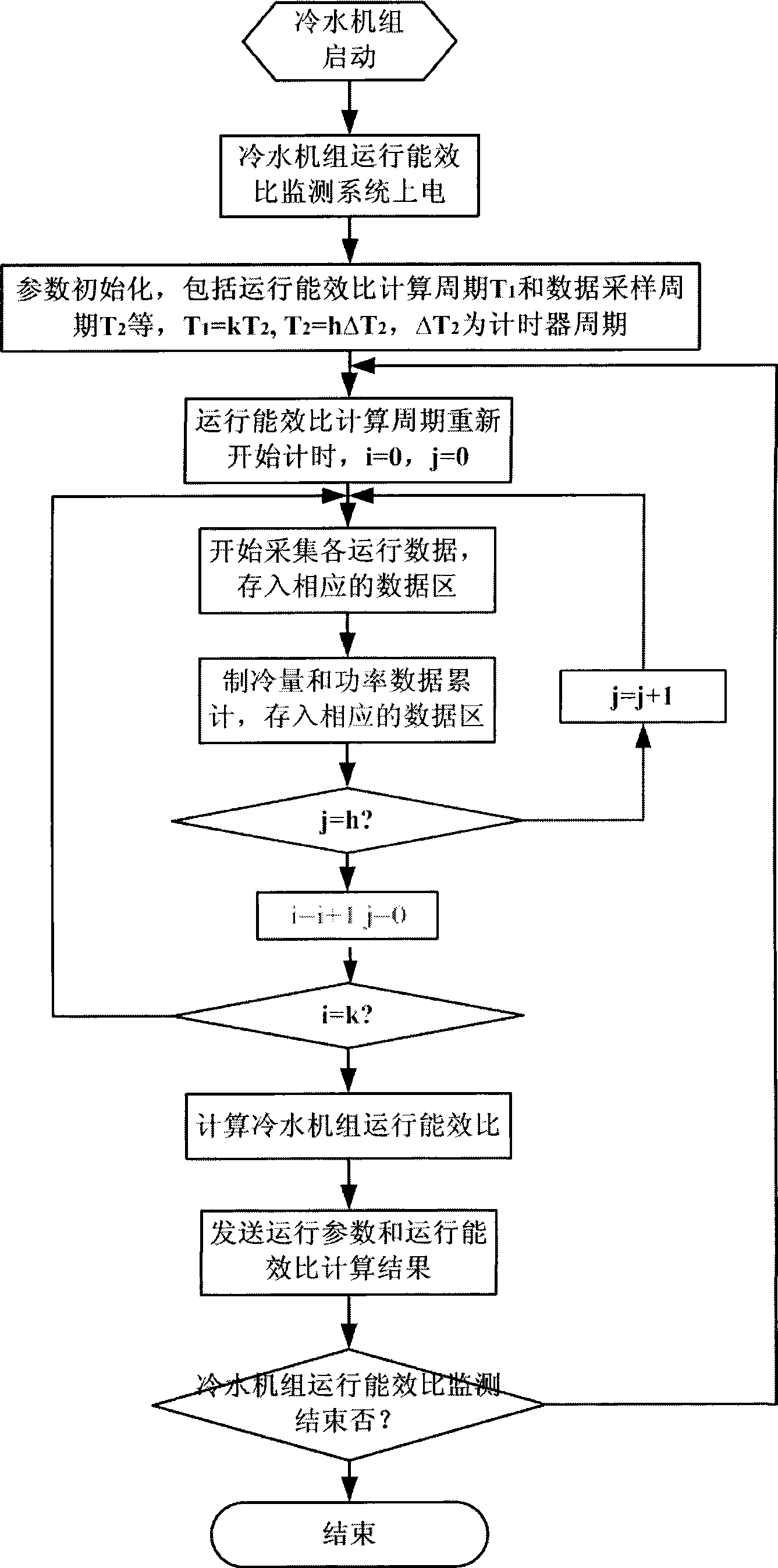

[0033] Such as figure 1As shown, the chiller operation energy efficiency ratio monitoring system of the present invention includes a chiller operation energy efficiency ratio monitoring controller, a remote monitoring computer, a local monitoring computer, a chilled water supply temperature sensor for a cooling pipe network connected to the chiller, and a cooling pipe network Chilled water return temperature sensor, chilled water flowmeter in the cooling pipe network, refrigeration compressor power sensor; among them, the local monitoring computer and the remote monitoring computer are respectively connected through the RS232 / RS-485 converter, (TCP / IP) / RS-485 The converter is signal-connected with the energy efficiency ratio monitoring controller for the operation of the chiller. The chilled water supply temperature sensor of the cooling pipe network, the chilled water return temperature sensor of the cooling pipe network, the chilled water flow meter of the cooling pipe netwo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com