Controlled rolling and controlled cooling production process of HRB400 (Hot-rolled Ribbed-steel Bar 400) steel bar

A production process, controlled rolling and controlled cooling technology, applied in the field of iron and steel metallurgy, can solve the problems of high price of trace alloying elements and high production costs, reduce production costs, enhance strength and plasticity, and achieve the effect of batch industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

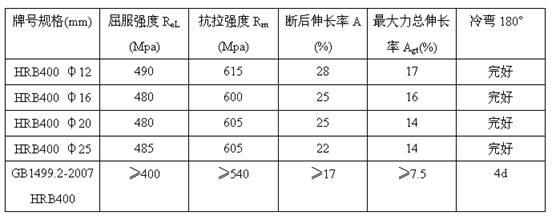

Image

Examples

Embodiment Construction

[0010] The continuous casting slab of 150×150×6000mm or 165×165×6000mm is heated by a three-stage continuous pusher type heating furnace and then rolled into a hot-rolled ribbed steel bar of φ10~φ32mm. The effective area of the furnace is 6.8×28.5㎡, and the fuel is hot Expansion of the furnace gas, the air volume of each burner and the opening of the flue gate valve are automatically controlled by electrical appliances, so as to realize the fully automatic control of the temperature of each section and the atmosphere in the furnace. At 1100~1300°C, the temperature of the soaking section is controlled at 1100~1250°C, the temperature of the steel billet is controlled at 1100~1200°C, and the tapping is automatically controlled by the ejector rod.

[0011] The starting rolling temperature is controlled at 1050~1150℃, and the final rolling temperature is controlled at 930~970℃. The rolling line implements full continuous rolling with 17 rolling mills, including 5 φ580 closed-end r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com