High-concentration CO sulfur-tolerant conversion process and its device

A sulfur-resistant shift, high-concentration technology, applied in inorganic chemistry, non-metallic elements, chemical instruments and methods, etc., can solve the problems of increasing the cost of the reactor, increasing the unsafe operation of the device, and the difficulty of stable operation of the device. Low inlet temperature, the effect of preventing the bed temperature from being too high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

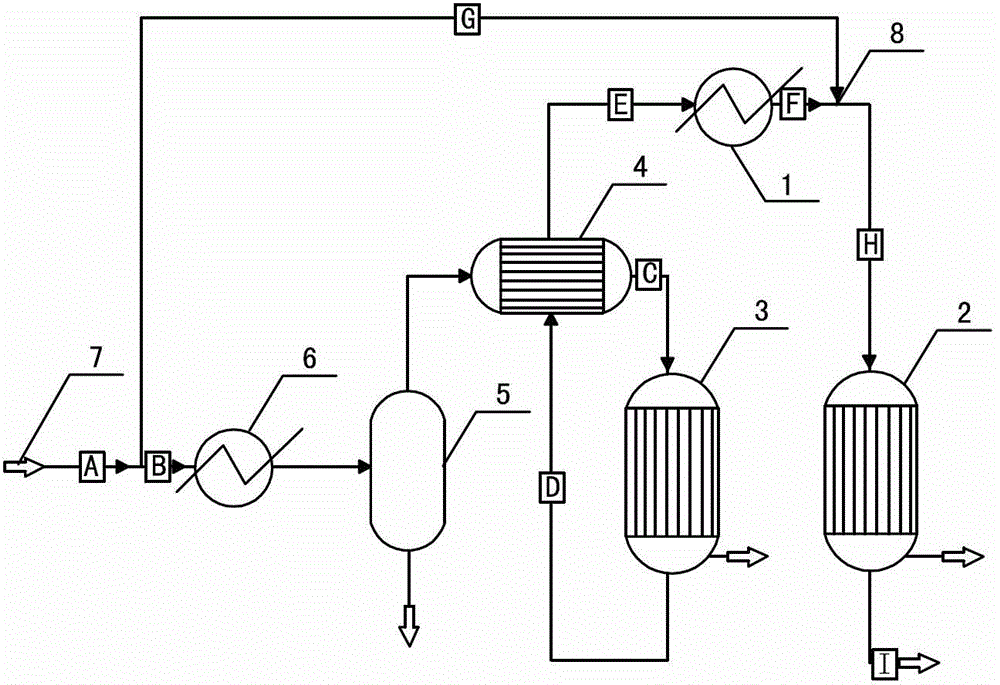

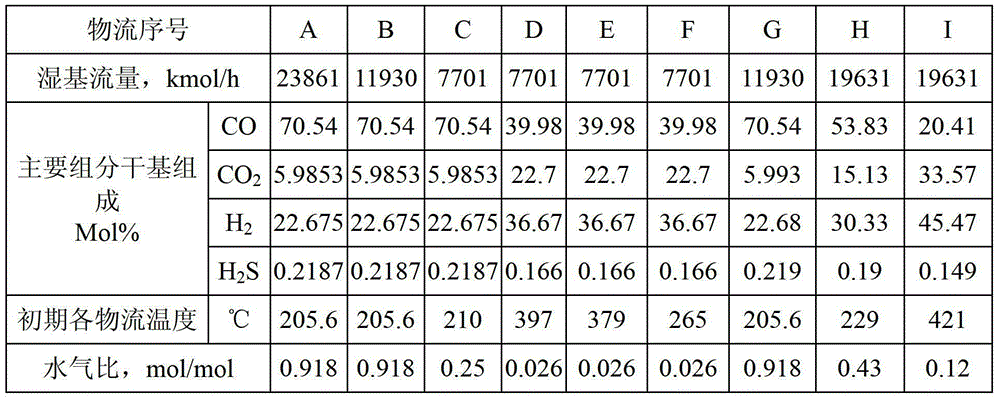

[0038] as attached figure 1 As shown in the data in Table 1: the raw gas (A) enters from the first gas inlet 7 and is divided into two streams (B and G), and one raw gas (B) is cooled by the low-pressure waste heat boiler 6 and dewatered by the gas-liquid separator 5 , reduce the molar ratio of water to gas to 0.25:1, and then exchange heat with the process gas (D) at the outlet of the first variable reactor 3 (D) to raise the temperature (C), and then enter the first variable reactor 3 for shift reaction. The process gas (D) at the outlet of the first variable reactor 3 passes through the gas-gas heat exchanger 4 to remove heat (E), then passes through the medium-pressure waste heat boiler 1 to further remove heat and cool down (F), and then enters with the second gas inlet 8 Another stream of raw gas (G) mixed (H) enters the second variable reactor 2 for two-stage shift reaction, so that the CO content in the second variable outlet gas (I) reaches 20.4mol% (dry basis). A, B...

Embodiment 2

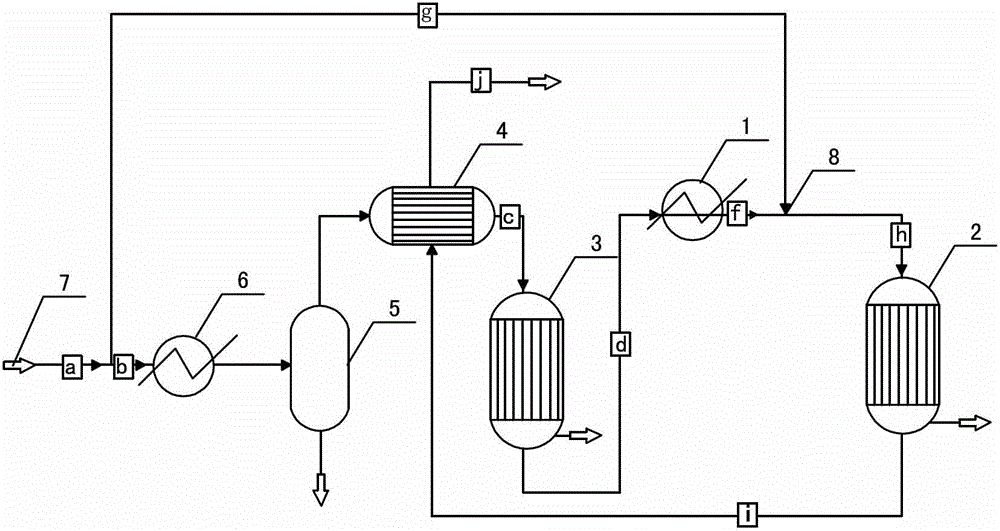

[0042] as attached figure 2 And the data shown in Table 2: the raw gas (a) is divided into two streams (b and g) after entering the first gas inlet 7, and one raw gas (b) is cooled by the low-pressure waste heat boiler 6 and removed by the gas-liquid separator 5 Water, reduce the molar ratio of water to gas to 0.31:1, and then enter the first variable reactor 3 for transformation reaction after heat exchange with the process gas (i) from the outlet of the second variable reactor 2 through the gas-gas heat exchanger 4 and increase the temperature (c). . The process gas (d) at the outlet of the first transformer reactor 3 is deheated and cooled by the medium-pressure waste heat boiler 1 (f), mixed with another raw gas (g) entering the second gas inlet 8, and then (h) enters the second transformer Reactor 2 performs a two-stage shift reaction, so that the CO content in the outlet gas (i) of the second shift reactor 2 reaches 17.8 mol% (dry basis). a, b, c, d, f, g, h, i, j are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com