Laundry detergent casting system and washing machine

A technology for a laundry liquid and a washing liquid box, which is applied in the field of washing machines, can solve the problems of different detergents that do not consider the demand for the amount of laundry detergent to condense and block the pipeline and the liquid outlet, and cannot realize the functions of self-cleaning and disinfectant liquid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

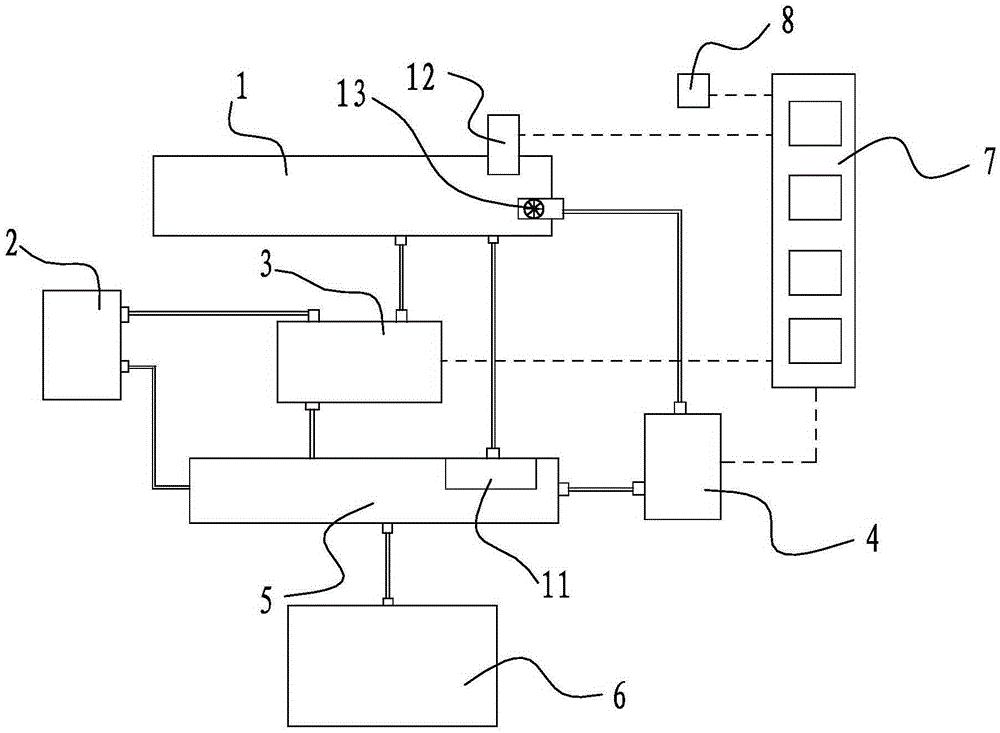

[0024] Such as figure 1 As shown, a laundry liquid dispensing system includes a washing liquid box 1 , a disinfectant liquid box 2 , a water inlet valve 3 , a quantitative pump 4 , a water box 5 , a washing tub 6 and a controller 7 . The washing liquid box 1 is connected with a liquid injection port 11 through a pipeline. The liquid injection port 11 is arranged in the space inside the water box 5. Since the washing liquid is frequently added, it will inevitably spill out during operation. The liquid injection port 11 is arranged on the In the space in the water box 5, the washing liquid spills out into the water box 5, and the washing liquid can enter the washing bucket 6 through the water box 5, so that the inner bucket in the washing machine can not be polluted, and the waste of washing liquid is avoided. The washing liquid box 1 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com