Method for preparing high-melting-point metal powder through multistage depth reduction

一种高熔点金属、深度的技术,应用在金属加工、工艺效率的提高、可持续制造/加工等方向,能够解决设备和安全的要求高等问题,达到设备要求低、工艺高效、工艺条件和仪器设备要求低的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

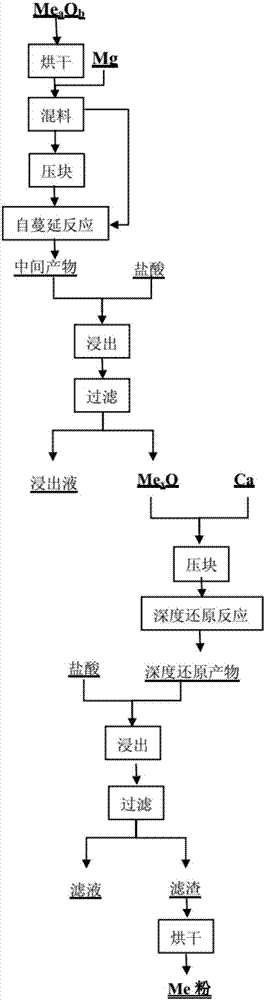

[0056] A method for preparing high-melting-point metal powder by multi-stage deep reduction is carried out according to the following steps:

[0057] Step 1, self-propagating reaction

[0058] Put the tungsten oxide powder in an oven and dry at 100-150°C for 24 hours to obtain the dried tungsten oxide powder. The molar ratio of the dried tungsten oxide powder and magnesium powder is WO 3 : Mg=1:1 mixed to obtain a mixed material, press the mixed material at 20MPa to obtain a block billet, put it into a self-propagating reaction furnace, and initiate a self-propagating reaction by means of partial ignition, the temperature is controlled at 500 ° C, after cooling , to obtain the subvalent oxide Me of the refractory metal x The intermediate product of O dispersed in the MgO matrix; among them, the subvalent oxide Me of the refractory metal x The intermediate product of O dispersed in the MgO matrix is a mixture of non-stoichiometric metal oxides with low valence and high melt...

Embodiment 2

[0068] A method for preparing high-melting-point metal powder by multi-stage deep reduction is carried out according to the following steps:

[0069] Step 1, self-propagating reaction

[0070] Put the tungsten oxide powder in an oven and dry at 100-150°C for 24 hours to obtain the dried tungsten oxide powder. The molar ratio of the dried tungsten oxide powder and magnesium powder is WO 3 : Mg=1:1.2 mixed to obtain a mixed material, press the mixed material under 10MPa to obtain a block billet, put it into a self-propagating reaction furnace, and initiate a self-propagating reaction by means of partial ignition, the temperature is controlled at 750 ° C, after cooling , to obtain the subvalent oxide Me of the refractory metal x The intermediate product of O dispersed in the MgO matrix; among them, the subvalent oxide Me of the refractory metal x The intermediate product of O dispersed in the MgO matrix is a mixture of non-stoichiometric metal oxides with low valence and high...

Embodiment 3

[0080] A method for preparing high-melting-point metal powder by multi-stage deep reduction is carried out according to the following steps:

[0081] Step 1, self-propagating reaction

[0082] Put the tungsten oxide powder in an oven and dry at 100-150°C for 24 hours to obtain the dried tungsten oxide powder. The molar ratio of the dried tungsten oxide powder and magnesium powder is WO 3 :Mg=1:0.8 mixed to obtain a mixed material, press the mixed material at 60MPa to obtain a block billet, put it into a self-propagating reaction furnace, and initiate a self-propagating reaction by means of partial ignition, the temperature is controlled at 650 ° C, after cooling , to obtain the subvalent oxide Me of the refractory metal x The intermediate product of O dispersed in the MgO matrix; among them, the subvalent oxide Me of the refractory metal x The intermediate product of O dispersed in the MgO matrix is a mixture of non-stoichiometric metal oxides with low valence and high mel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com