Method for preparing catalytic cracking catalyst

A catalytic cracking and catalyst technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, molecular sieve catalyst, etc., can solve the problems of ammonia nitrogen pollution, waste of manpower and material resources, heavy economic burden, etc., to eliminate ammonia nitrogen pollution and reduce wastewater treatment Cost, effect of enhancing activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

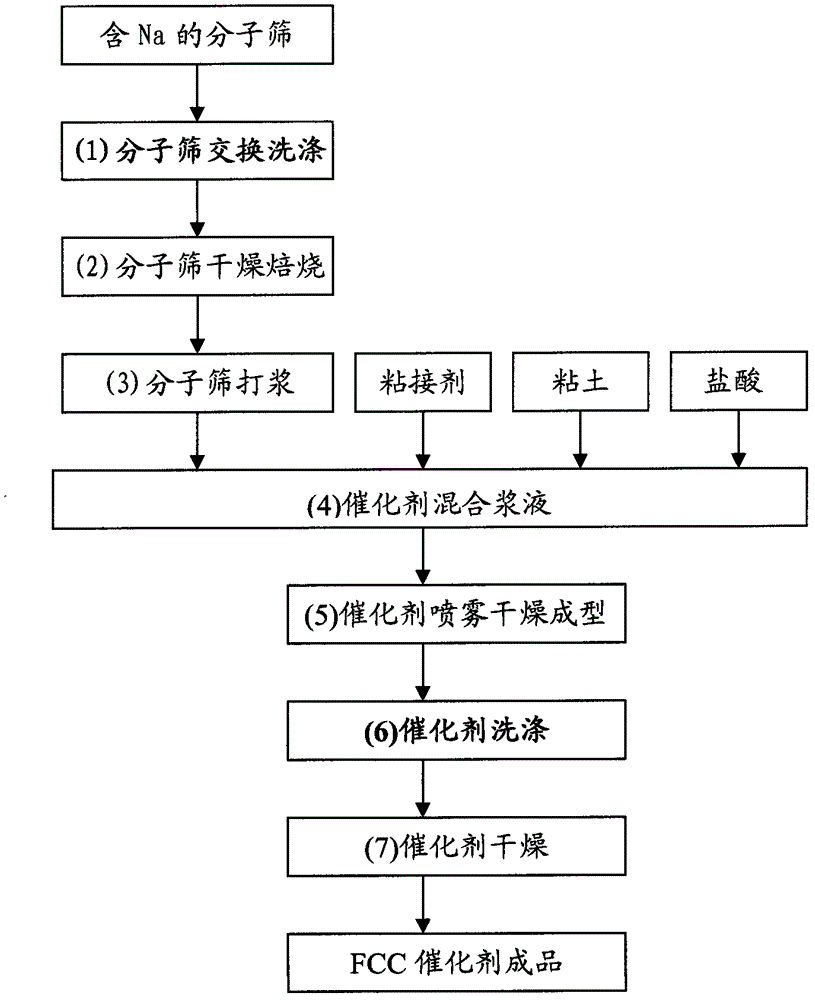

[0021] In the catalytic cracking catalyst preparation method provided by the present invention, the molecular sieve is contacted with the aqueous solution containing organic acid and inorganic acid for 0.5-3 hours, and then separated, and the separated molecular sieve may also include the steps of washing, drying and roasting. Separation, washing, drying, and roasting methods are well known to those skilled in the art. For example, the separation can use the method of filtration to separate the exchanged molecular sieve from the mother liquor; the molecular sieve can be washed with deionized water; it can be heated in an air drying oven. Or dry and roast the molecular sieve by flash drying method. The molecular sieve obtained through the above steps is called the molecular sieve obtained by low-temperature mixed acid exchange.

[0022]According to the preparation method of catalytic cracking catalyst provided by the present invention, in the catalyst washing step, the catalyst...

Embodiment 1

[0035] The preparation of present embodiment catalytic cracking catalyst comprises the following steps:

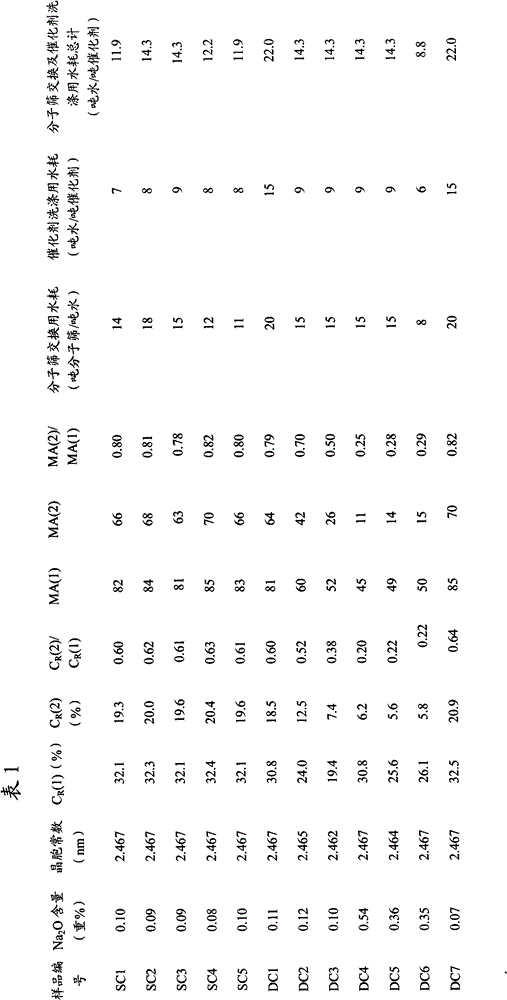

[0036] (1) Exchange washing of Y-type molecular sieves containing Na: take 2.7 kilograms of acetic acid, add appropriate amount of cold water and stir to make it dissolve, then add 8.1 kilograms of hydrochloric acid with a concentration of 36% by weight, then continue to add cold water to dilute the solution to 1000L to form H + Mixed acid solution with a molar concentration of 0.17mol / L, control the solution temperature: 3.5±0.5°C, add 71.4 kg of Y-type molecular sieve powder dry basis (H 2 O: The weight ratio of molecular sieve raw powder dry basis=14:1), then stirred and reacted at 3.5±0.5°C for 2 hours, then filtered the slurry, and used deionized water 5 times the dry basis weight of Y-type molecular sieve raw powder for the filter cake rinse;

[0037] (2) flash drying the product of step (1) and roasting at 550° C. for 3 hours;

[0038] (3) preparing molecular siev...

Embodiment 2

[0045] The catalytic cracking catalyst was prepared according to the method in Example 1, except for step (1) and step (6).

[0046] (1) Exchange and washing of Na-containing Y-type molecular sieves: Weigh 5.67 kilograms of oxalic acid and add an appropriate amount of cold water to stir to dissolve it, then add 15.75 kilograms of nitric acid with a concentration of 20% by weight, then continue to add cold water to dilute the solution to 1000L to form H + Mixed acid solution with a molar concentration of 0.14mol / L, control the solution temperature: 4.5±0.5°C, add 55.6 kg of Y-type molecular sieve powder on a dry basis (molecular sieve exchange liquid, H 2 O: The weight ratio of molecular sieve raw powder dry basis=18:1), then stirred and reacted at 4.5±0.5°C for 2.5 hours, then filtered the slurry, and used deionized water 5 times the dry basis weight of Y-type molecular sieve raw powder for the filter cake rinse;

[0047] (6) Catalyst washing: take by weighing 1134 grams of o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com