Method and device for washing compressor flow passage of gas-steam combined generating set

A technology for generator sets and flow parts, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problems of unclear washing process requirements, unreasonable washing cycles, and poor washing effects, etc. To achieve the effect of avoiding unstable data sources, ensuring washing effect, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

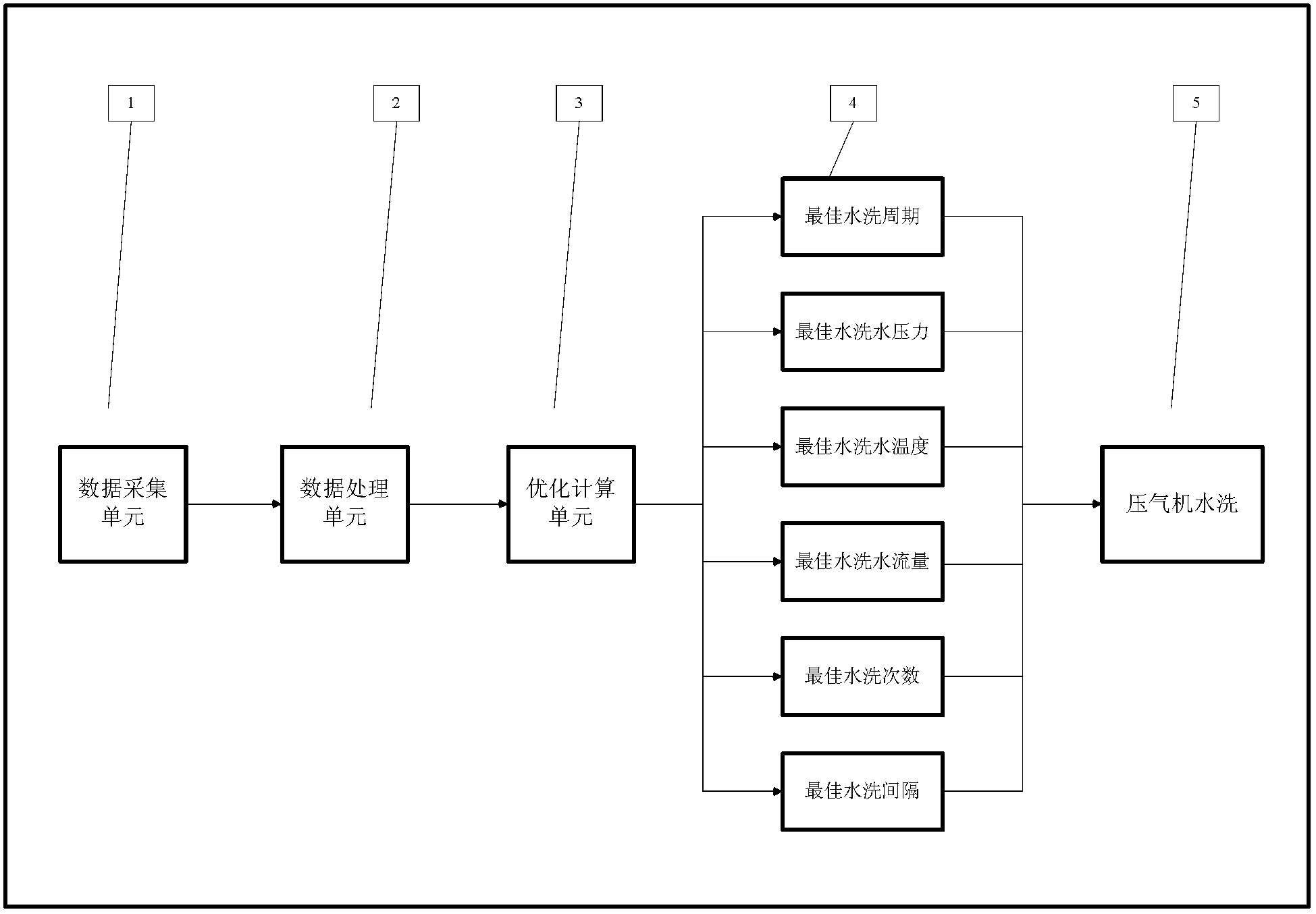

[0053] refer to figure 1 , the gas-steam combined generator unit compressor flow part water washing device involved in the present implementation includes compressor water washing equipment 5, and a control mechanism is set at the control input end of the compressor water washing equipment 5, and the control mechanism is composed of data acquisition unit 1, The data processing unit 2, the optimization calculation unit 3 and the control unit 4 constitute, the signal output end of the acquisition unit 1 is connected to the signal input end of the optimization calculation unit 3 through the data processing unit 2, and the signal output end of the optimization calculation unit 3 is connected through the control unit 4 The control signal input terminal of the water washing equipment 5 of the compressor; the data acquisition unit 1 is provided with a real-time data acquisition input terminal, and the load, atmospheric pressure, atmospheric temperature, atmospheric humidity, natural g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com