Moving bed smoke desulfur denitrate and dust removal technology

A desulfurization and denitrification, moving bed technology, applied in the field of flue gas purification, can solve the problems of difficult separation of CO gas, no reflection of denitrification and dust removal process, and difficulty of upward moving process, etc., to achieve good effect, improve efficiency and low operating cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0030] An industrial side line is built on the main flue of a 600,000-kilowatt thermal power plant boiler in Inner Mongolia. The flue gas flow rate and main indicators of the side line are as follows:

[0031] Flow 10000Nm 3 / h,SO 2 2500mg / Nm 3 , NO x 510mg / Nm 3 , Dust 100mg / Nm 3 , dry basis oxygen 6%, temperature 150 ℃.

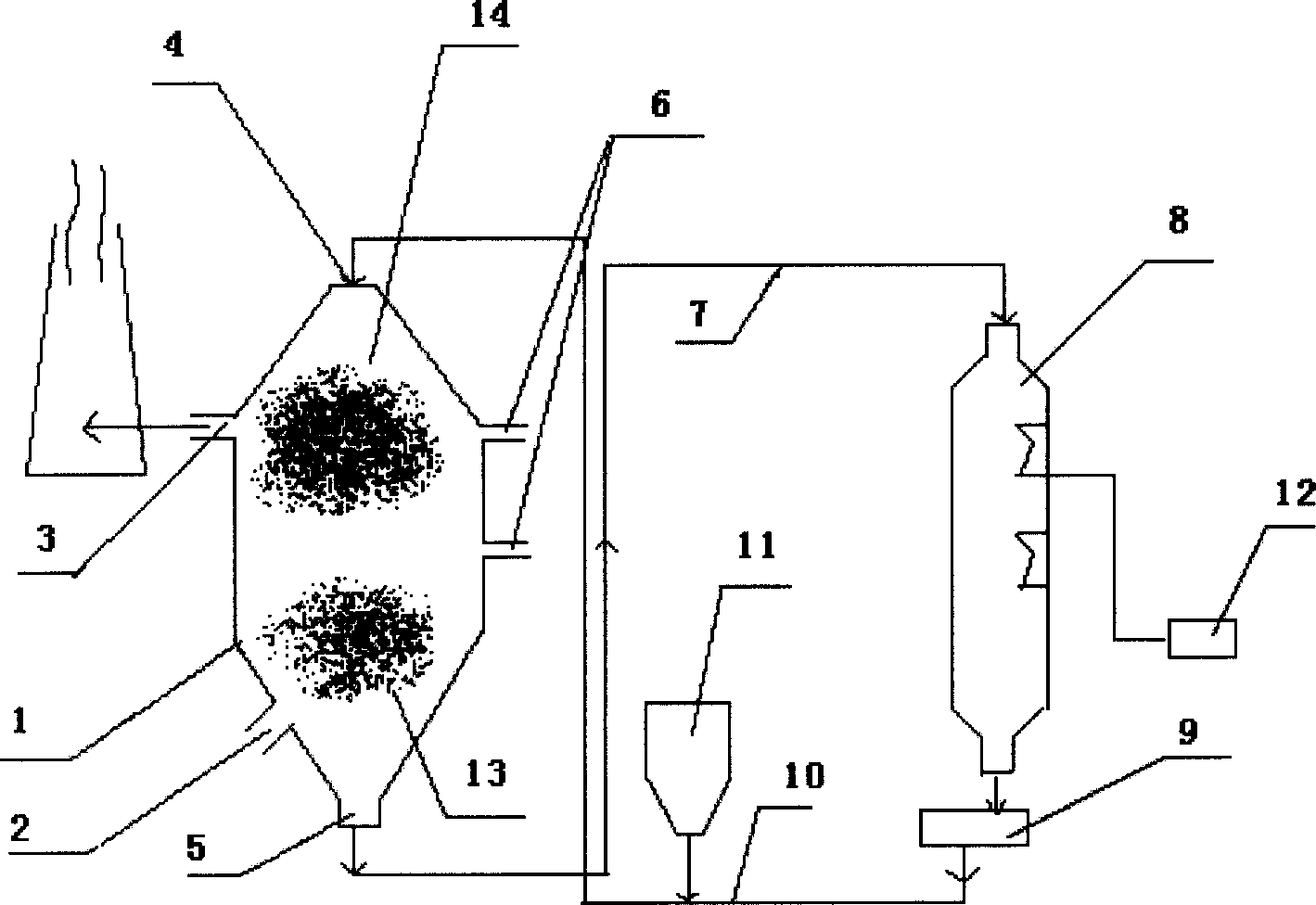

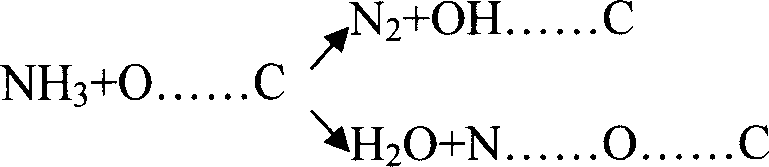

[0032] The desulfurization and denitrification reactor 1 is filled with 10 tons of desulfurization, denitrification and dedusting active coke disclosed in CN200610017059.7, and the new active coke hopper 11 is equipped with 5 tons of active coke for mobile replenishment. Start the system, let in the flue gas, the active coke starts to move, and the amount of ammonia injected at the ammonia injection port 6 is based on the flue gas flow and NO x The content is determined to be 5000-7500g / h; the activated coke discharged through the discharge port 5 is sent to the regeneration tower 8 for regeneration, and is heated and regenerated at 500°C for 5-10 hou...

example 2

[0034] An industrial side line is built on the main flue of a 200,000-kilowatt thermal power plant boiler in Northeast China. The flue gas flow rate and main indicators of the side line are as follows:

[0035] Flow 7000Nm 3 / h,SO 2 3800mg / Nm 3 , NO x 500mg / Nm 3 , Dust 100mg / Nm 3 , dry basis oxygen 6%, temperature 180 ℃.

[0036] The desulfurization and denitrification reactor 1 is filled with 8 tons of desulfurization, denitrification and dedusting active coke disclosed in CN200610017059.7, and the new active coke hopper 11 is equipped with 4 tons of active coke for mobile replenishment. Start the system, let in the flue gas, the active coke starts to move, and the amount of ammonia injected at the ammonia injection port 6 is based on the flue gas flow and NO x The content is determined to be 4000-6000g / h; the activated coke discharged through the discharge port 5 is sent to the regeneration tower 8 for regeneration, and is heated and regenerated at 400°C for 10-15 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com