Silicon block cleaning and drying device

A technology of drying device and silicon block, which is applied in the directions of cleaning flexible items, cleaning methods and utensils, cleaning methods using liquids, etc., which can solve customer product quality doubts, unqualified downstream product quality, and inability to completely remove metal impurities silicon powder and scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment provides a silicon block cleaning and drying device, which includes a cleaning unit, a drying unit and a cooling unit.

[0037] The cleaning unit is used to clean the surface of the crushed silicon block to remove surface residues (metal impurities and silicon powder) and scratches; the drying unit is used to clean the silicon block after cleaning. The drying process is to thoroughly dry the moisture on the surface; the cooling unit is used to cool the dried silicon block to a temperature suitable for the downstream packaging process.

[0038] The silicon block washing and drying device described in this embodiment can not only remove the residue on the surface of the silicon block, but also dry the moisture on the surface of the silicon block, and can also cool the silicon block to a temperature suitable for packaging.

Embodiment 2

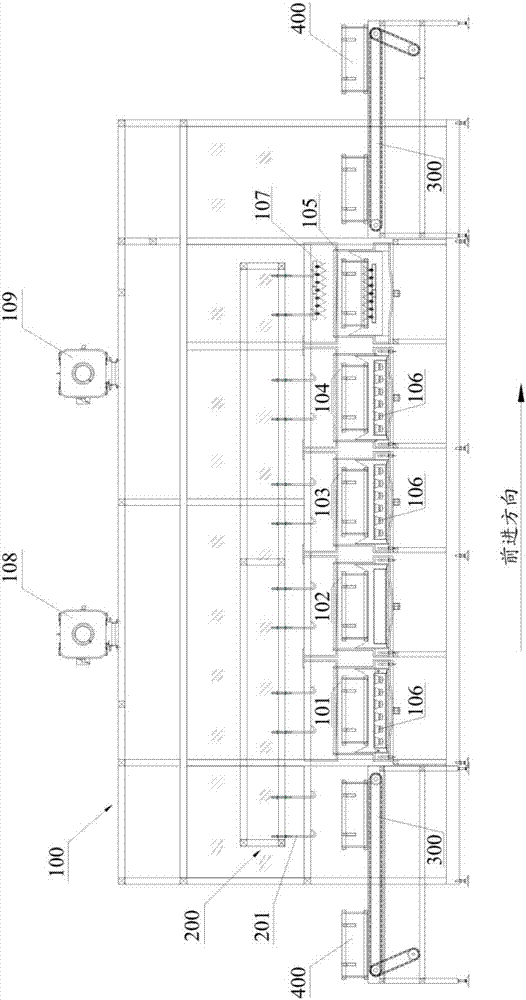

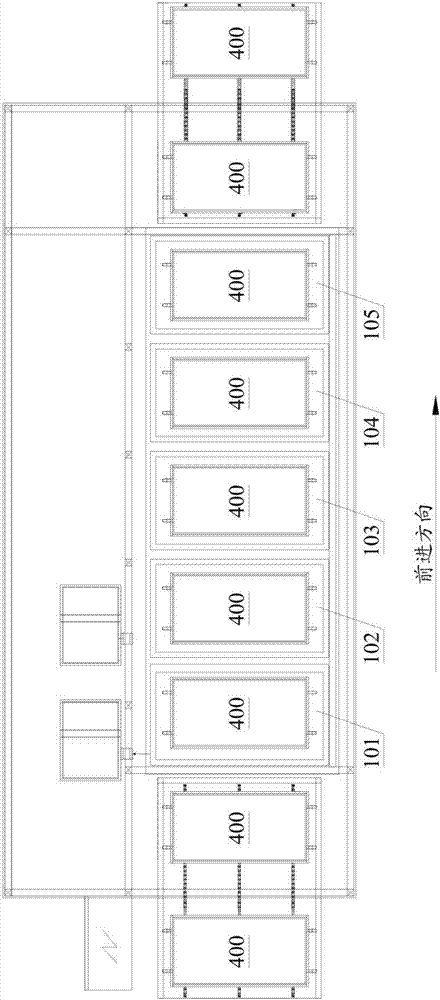

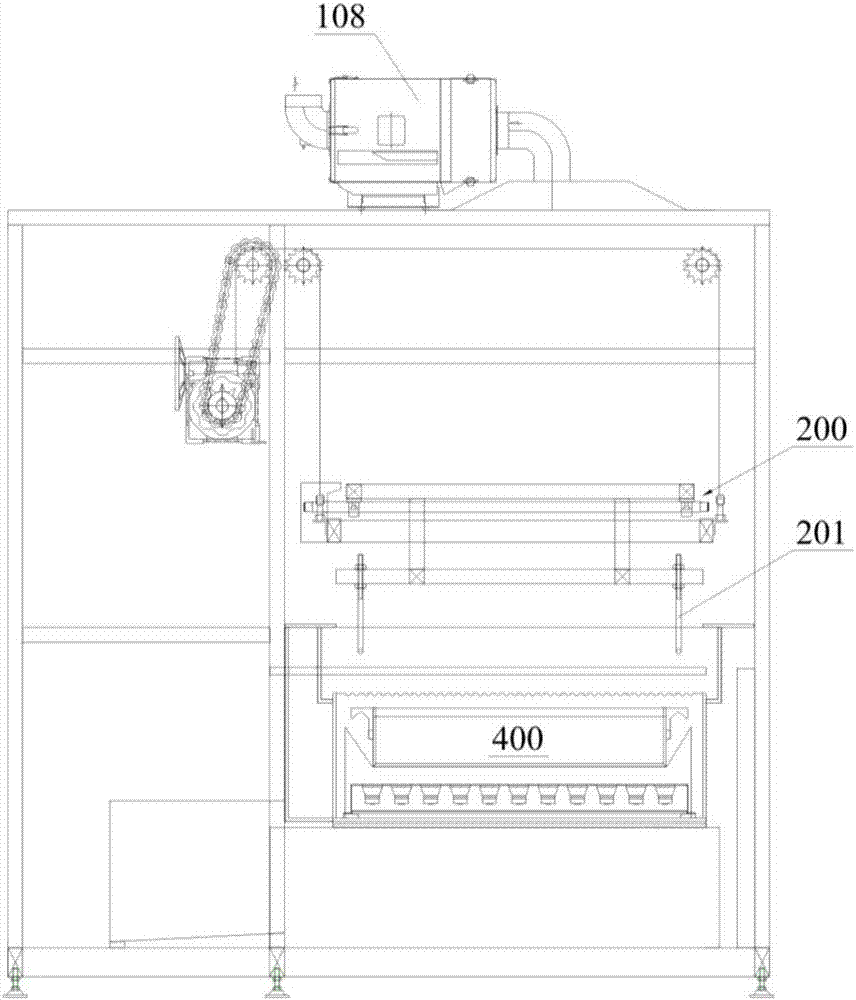

[0040] This embodiment provides a silicon block cleaning and drying device, such as Figure 1~6 As shown, the silicon block cleaning and drying device includes a cleaning unit 100 , a drying unit 500 , a cooling unit 600 , a conveying unit 300 and a material basket 400 . The arrows in the figure indicate the forward direction of the basket 400 .

[0041] In this embodiment, the crushed silicon blocks from the feedway of the silicon crushing system are placed in the material basket 400 . The material basket 400 is made of PP (Polypropylene, polypropylene) material or PVDF (Poly (vinylidene fluoride), polyvinylidene fluoride) material injection molding, and its 5 panels (ie front panel, rear panel, left panel, right panel and bottom panel) ) are evenly arranged with holes with a diameter of 3 to 5 mm, and the hole spacing is about 10 mm. The length of the material basket 400 is about 1000mm, the width is about 500mm, the height is about 200mm (not including the hook part), and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com