Washing machine

A technology for washing machines and laundry, applied in the field of washing machines, can solve the problems of no foreign object cleaning method and insufficient cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Some preferred embodiments of the present invention are described below with reference to the accompanying drawings.

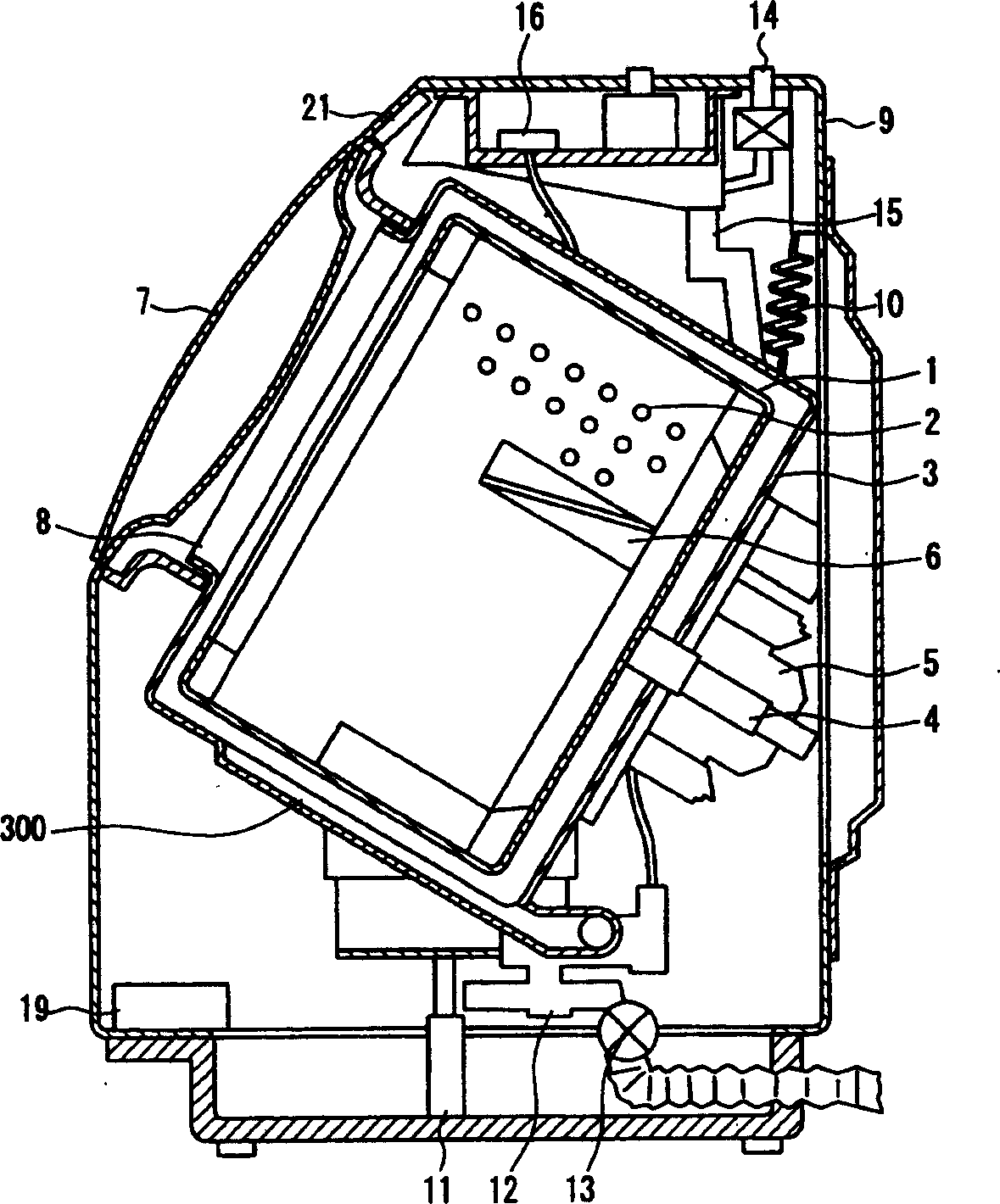

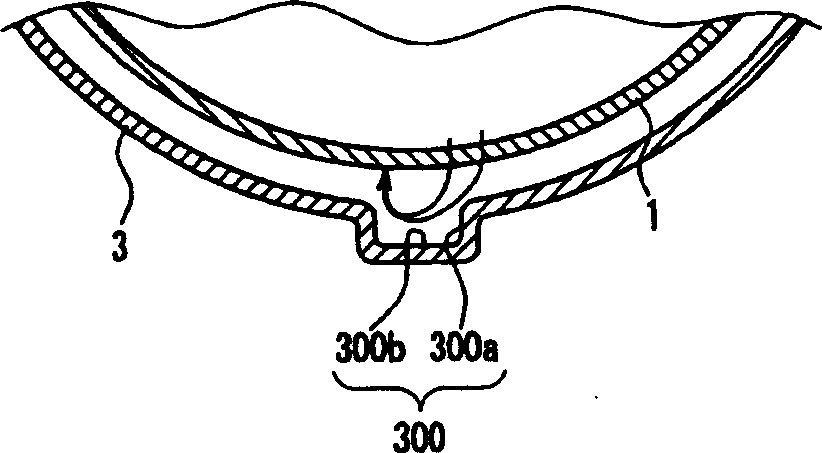

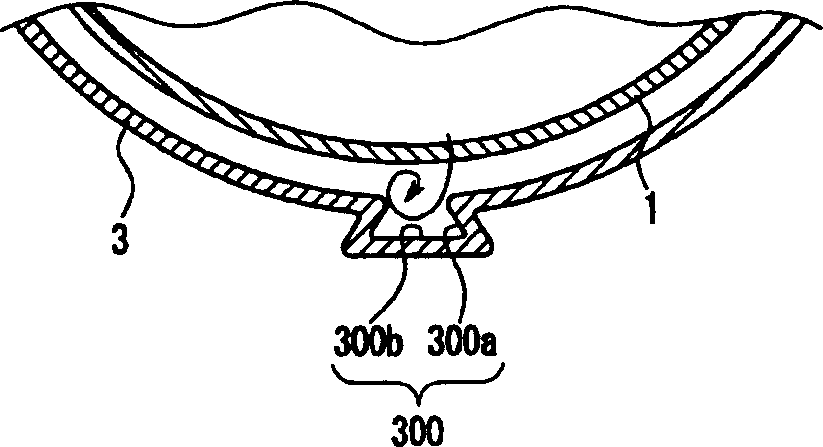

[0031] figure 1It is a sectional view showing a structural example of a washing machine in an embodiment of the present invention. exist figure 1 Among them, the rotary drum 1 is made into a cylindrical shape with a bottom, a large number of water holes 2 are provided on the entire outer wall surface, and it is arranged in a water tub 3 in a rotatable manner. The direction of the axis of the rotating drum 1 is inclined downward from the front side to the back side, and the rotating shaft 4 is arranged in an inclined direction consistent with the rotation center of the rotating drum 1 . The rotating shaft 4 is connected with the motor 5 located at the back side of the water tub 3, and the rotating drum 1 is driven by the motor 5 to rotate forwardly and reversely. A plurality of protruding plates 6 are provided on the inner wall surface of the rotary d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com