Reaction kettle for rare-earth metallurgy

A reactor, rare earth technology, applied in chemical/physical/physical-chemical stationary reactors, chemical/physical/physical-chemical mobile reactors, mixers, etc., can solve uneven stirring, incomplete cleaning, and work efficiency. lower problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

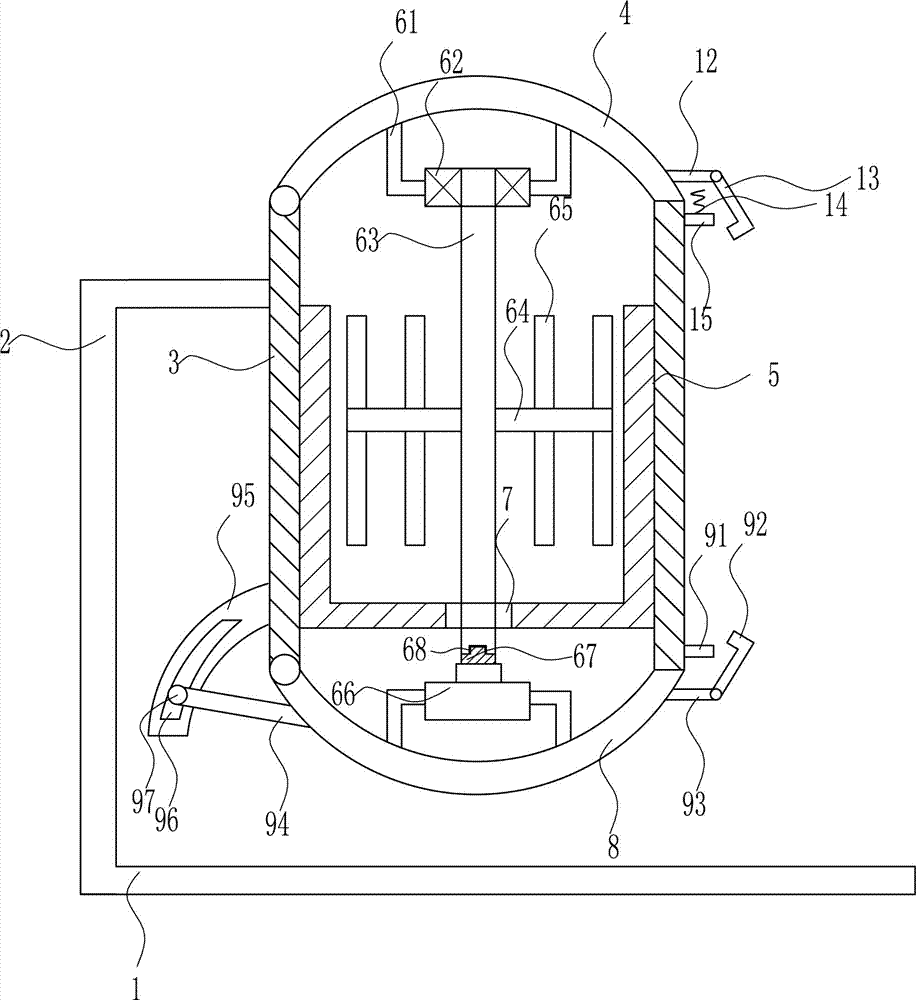

[0034] A reactor for rare earth metallurgy, such as Figure 1-5 As shown, it includes a bottom plate 1, a left bracket 2, a reaction kettle 3, an upper cover body 4, a mixing box 5, a stirring device 6, a lower cover body 8 and a locking device 9, and a left bracket 2 is provided on the left side of the top of the bottom plate 1. , the right end of the left bracket 2 is provided with a reactor 3, the upper and lower ends of the left side of the reactor 3 are hingedly connected with an upper cover 4 and a lower cover 8, the reactor 3 is provided with a mixing box 5, and the mixing box 5 is provided with a There is a stirring device 6, a through hole 7 is opened in the middle of the bottom of the mixing box 5, and a locking device 9 is provided at the bottom of the reaction kettle 3.

Embodiment 2

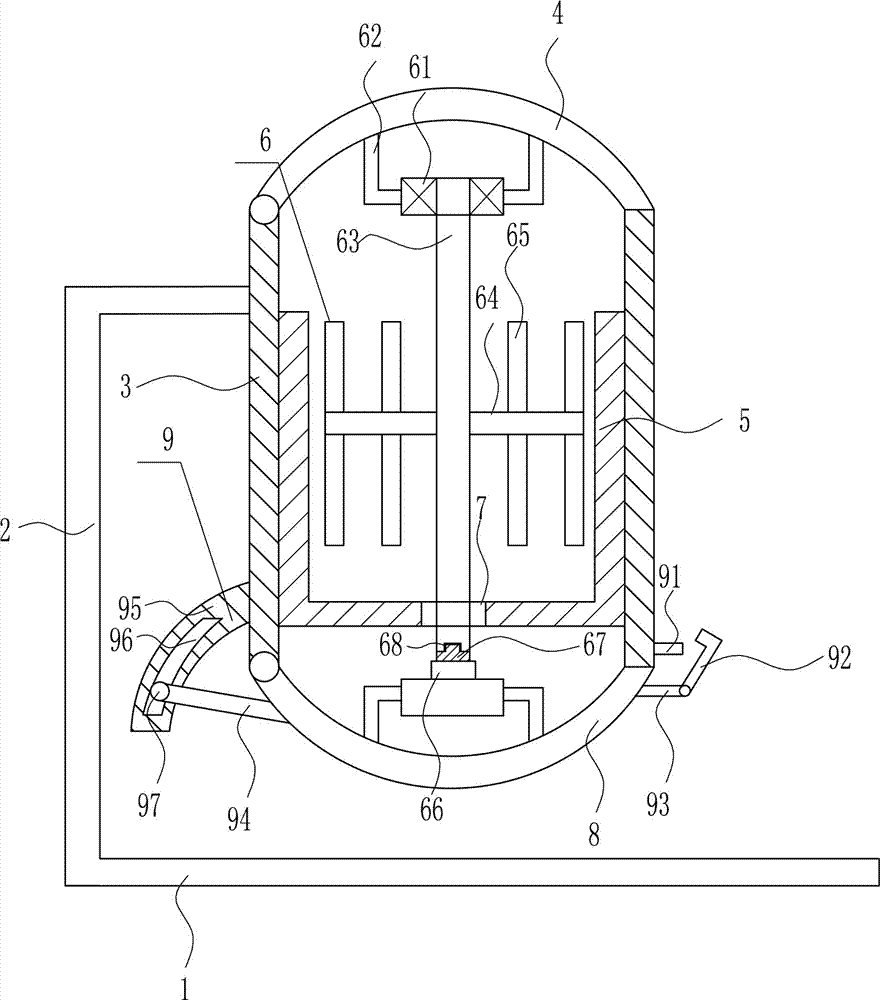

[0036] A reactor for rare earth metallurgy, such as Figure 1-5 As shown, it includes a bottom plate 1, a left bracket 2, a reaction kettle 3, an upper cover body 4, a mixing box 5, a stirring device 6, a lower cover body 8 and a locking device 9, and a left bracket 2 is provided on the left side of the top of the bottom plate 1. , the right end of the left bracket 2 is provided with a reactor 3, the upper and lower ends of the left side of the reactor 3 are hingedly connected with an upper cover 4 and a lower cover 8, the reactor 3 is provided with a mixing box 5, and the mixing box 5 is provided with a There is a stirring device 6, a through hole 7 is opened in the middle of the bottom of the mixing box 5, and a locking device 9 is provided at the bottom of the reaction kettle 3.

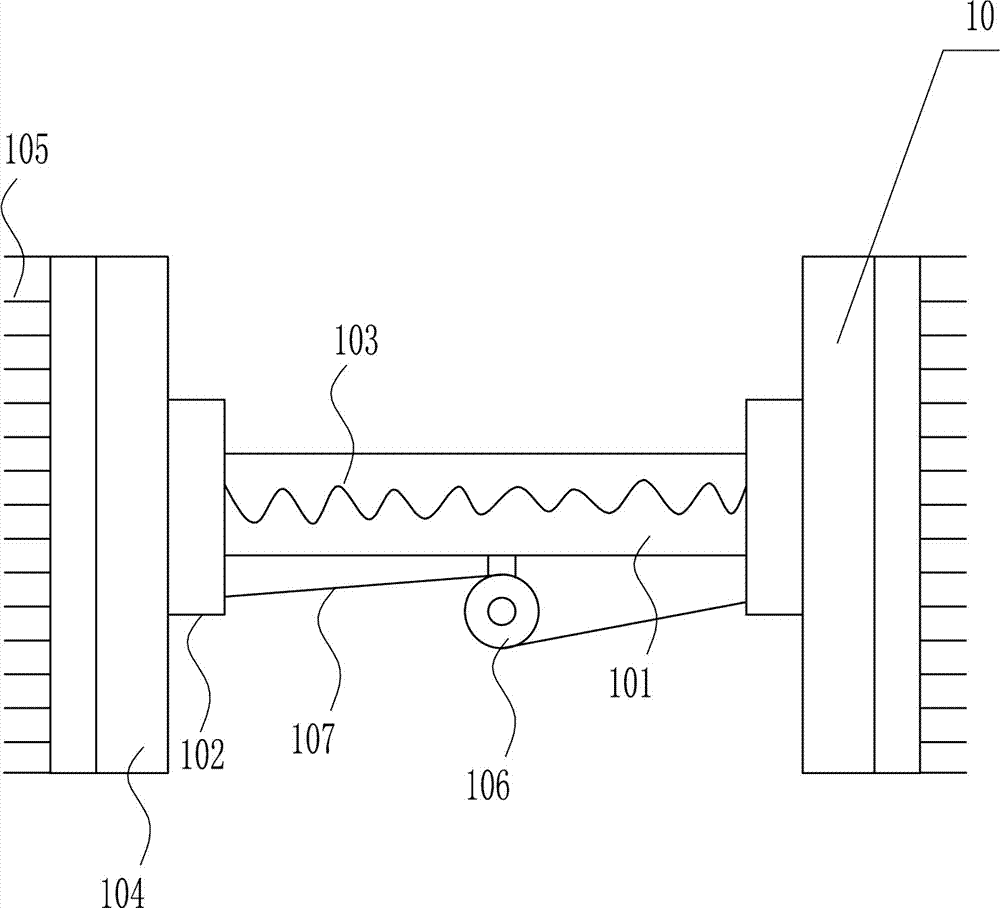

[0037] Stirring device 6 comprises bearing seat 61, n-shaped frame 62, rotating shaft 63, cross bar 64, stirring rod 65, first motor 66 and square projection 67, upper cover body 4 bottom and lowe...

Embodiment 3

[0039] A reactor for rare earth metallurgy, such as Figure 1-5 As shown, it includes a bottom plate 1, a left bracket 2, a reaction kettle 3, an upper cover body 4, a mixing box 5, a stirring device 6, a lower cover body 8 and a locking device 9, and a left bracket 2 is provided on the left side of the top of the bottom plate 1. , the right end of the left bracket 2 is provided with a reactor 3, the upper and lower ends of the left side of the reactor 3 are hingedly connected with an upper cover 4 and a lower cover 8, the reactor 3 is provided with a mixing box 5, and the mixing box 5 is provided with a There is a stirring device 6, a through hole 7 is opened in the middle of the bottom of the mixing box 5, and a locking device 9 is provided at the bottom of the reaction kettle 3.

[0040] Stirring device 6 comprises bearing seat 61, n-shaped frame 62, rotating shaft 63, cross bar 64, stirring rod 65, first motor 66 and square projection 67, upper cover body 4 bottom and lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com