Method and equipment for cleaning turbofan gas turbine engine

A technology for gas turbines and engines, applied to cleaning methods and appliances, cleaning methods using liquids, gas turbine devices, etc., can solve the problems of not being able to provide effective cleaning of engines, not being able to maintain manifolds with cones, and achieve lower temperatures and increased durability Sexuality and cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

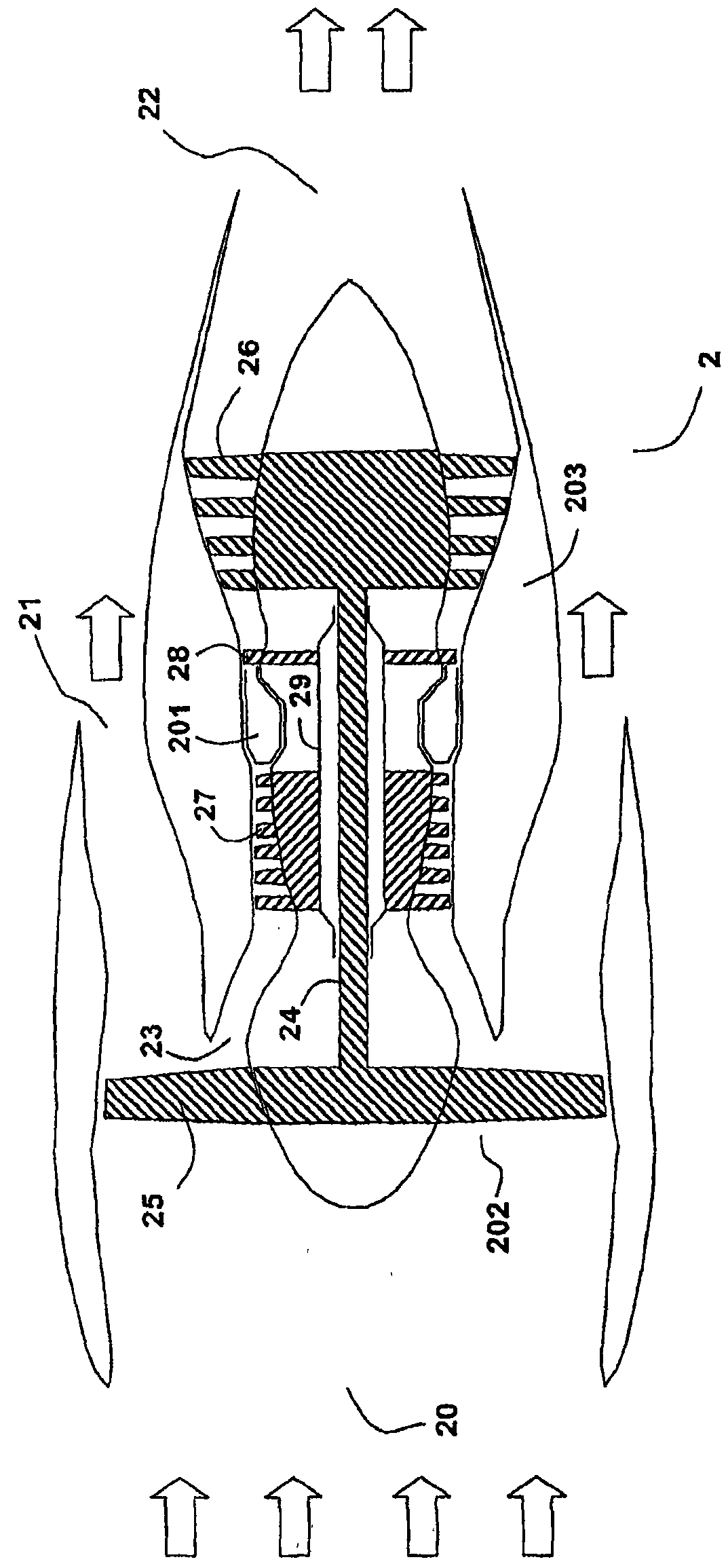

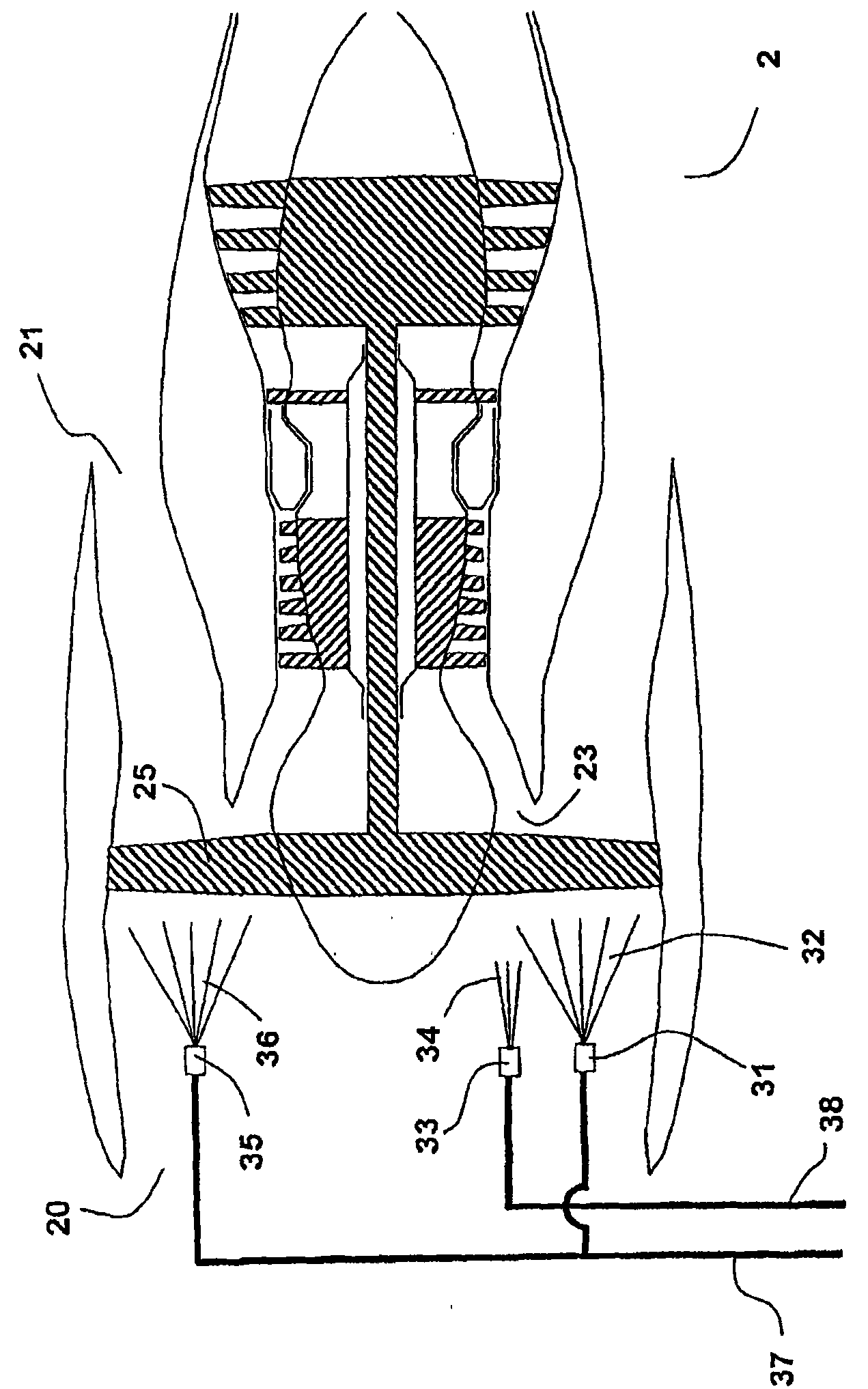

[0042] refer to figure 2 , a two-shaft non-hybrid turbofan aeroengine will be described. The twin-shaft non-hybrid turbofan engine is one of several possible turbofan engine designs. Since it is obvious that the invention can be applied to other variants of turbofan engines such as hybrid turbofan engines or turbofan engines with single, three or more shafts, this embodiment and its variants cannot be described in terms of The drawings limit the invention. A turbofan engine in which the invention is suitable for practice is characterized in that the fan and its cones for dividing the air flow are rotating.

[0043] exist figure 2 The engine 2 includes a fan unit 202 and a core engine unit 203 . The engine is built around a rotor shaft 24 which is connected at its front end to a fan 25 and at its rear end to a turbine 26 . The turbine 26 drives the fan 25 . The second axis 29 is in the form of being coaxial with the first axis 24 . At its front end a shaft 29 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com