Against corrosion film stripper composition

A technology of composition and stripping agent, applied in detergent compositions, surface-active detergent compositions, inorganic non-surface-active detergent compositions, etc., can solve problems such as corrosion of metal wiring and easy change of ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

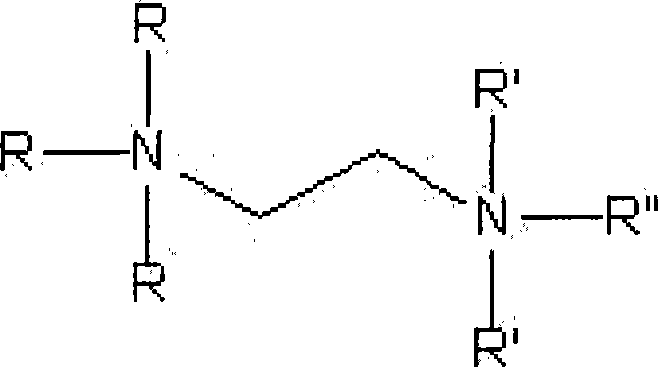

Method used

Image

Examples

Embodiment

[0051]Experiment 1 and Experiment 2 were carried out to select amines and corrosion inhibitors, and the test pieces used in the experiments are as follows.

[0052] Test pieces used in Experimental Example 1 and Experimental Example 2 (test piece 1, test piece 2)

[0053] First, test pieces for evaluating the corrosion ability to metals were prepared in the following manner. That is, after forming a thin film (fim formation) of aluminum (aluminum), molybdenum (molybdenum), and copper (copper) with a thickness of about 2000 Ȧ on the glass surface, a resist film is applied and developed to prepare a test piece 1 .

[0054] Second, a test piece for evaluation of resist stripping performance was prepared in the following manner. That is, after forming a thin film of chromium (Cr) on the glass surface, a resist film is applied, wet etching is performed, and dry etching gas is supplied to form n+a-Si: H activation film (active film) test piece 2. In addition, in order to form a...

experiment example 1

[0056] Using test piece 2 and test piece 3, the resist stripping performance of a single raw material was evaluated; and using test piece 1, the corrosion ability of aluminum, molybdenum and copper was evaluated, and the results are shown in Table 1.

[0057] [Table 1]

[0058] evaluation on metal

Membrane Corrosion Degree

Stripping performance of resist film

aluminum

molybdenum

copper

70°C, soak for 20 minutes

70℃, impregnated

30 seconds (test piece

3)

70℃, impregnated

30 seconds (test piece

2)

Monoethanolamine

×

×

×

◎

◎

1-(2-Hydroxyethyl)piperazine

○

○

○

△

○

1-(2-Aminoethyl)piperazine

○

○

×

○

◎

1-(2-Hydroxyethyl)-4-methylpiperazine

◎

◎

◎

△

○

N-(3-Aminopropyl)morpholine

△

△

×

○

◎

2-Methylpiperazine

...

experiment example 2

[0066] As shown in Table 2, test piece 1 was used to test the corrosion resistance of monoethanolamine and various amines used in the present invention to metal. For the amines that had a problem with the resist film peeling performance in the independent evaluation, experiments were conducted using two kinds of amines. In addition, since there are some corrosion phenomena for each metal in the above-mentioned independent evaluation, a compound containing 45 wt% of glycol ether, 45 wt% of polar solvent diethylene glycol butyl ether and 10% of two or one amines is used. The solution was tested and the results are shown in Table 2.

[0067] [Table 2]

[0068] Corrosion degree of metal wiring

aluminum

molybdenum

copper

Monoethanolamine

○

○

×

1-(2-Hydroxyethyl)piperazine

◎

◎

◎

1-(2-Aminoethyl)piperazine

◎

◎

×

N-(3-Aminopropyl)morpholine

○

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com