Self-cleaning filter capable of realizing double-sided backwashing

A kind of backwashing and filter technology, which is applied in the direction of fixed filter element filter, gravity filter, filtration separation, etc., can solve the problems of low filtration performance, poor filter backwashing effect, small pressure difference, etc., and achieve complete cleaning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

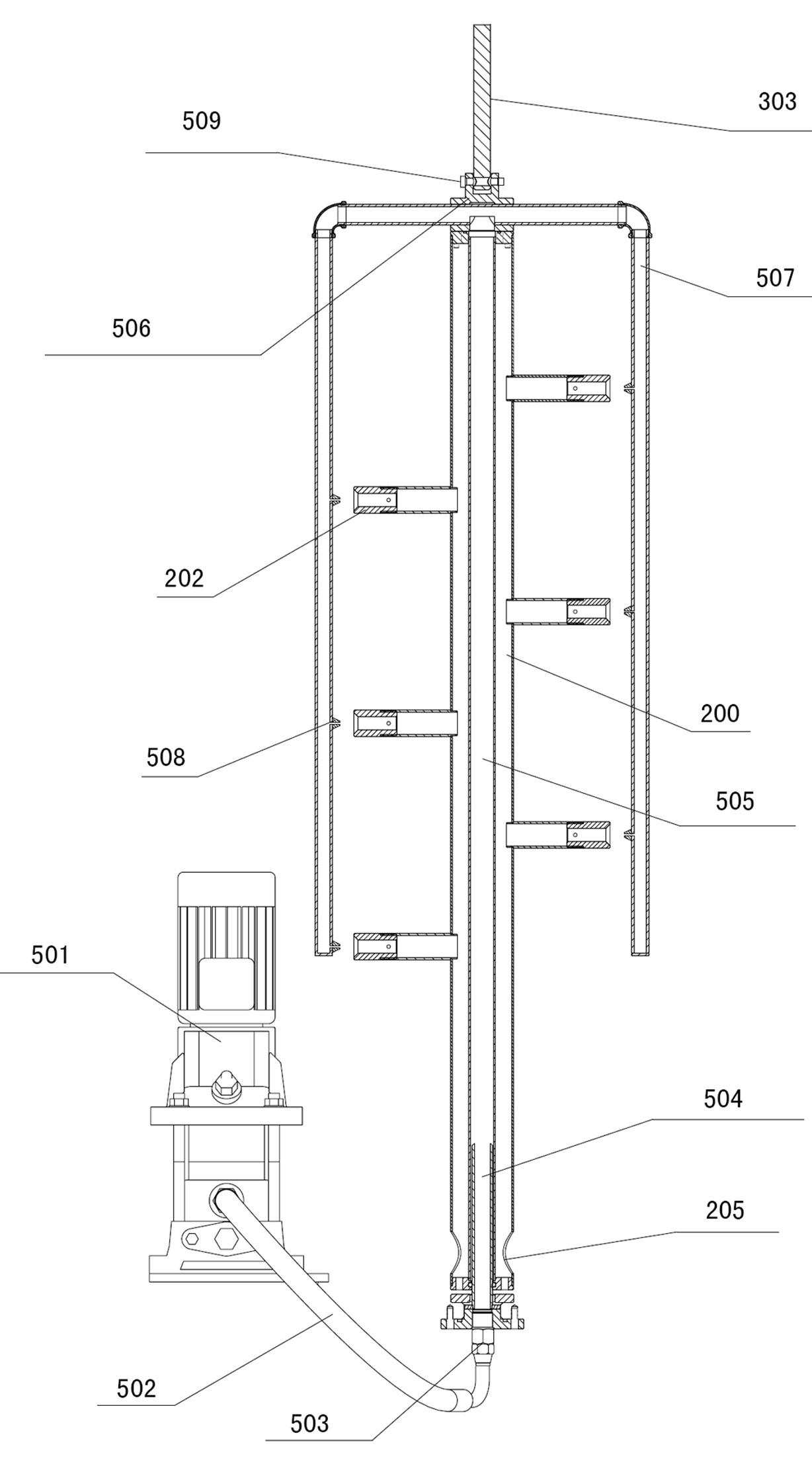

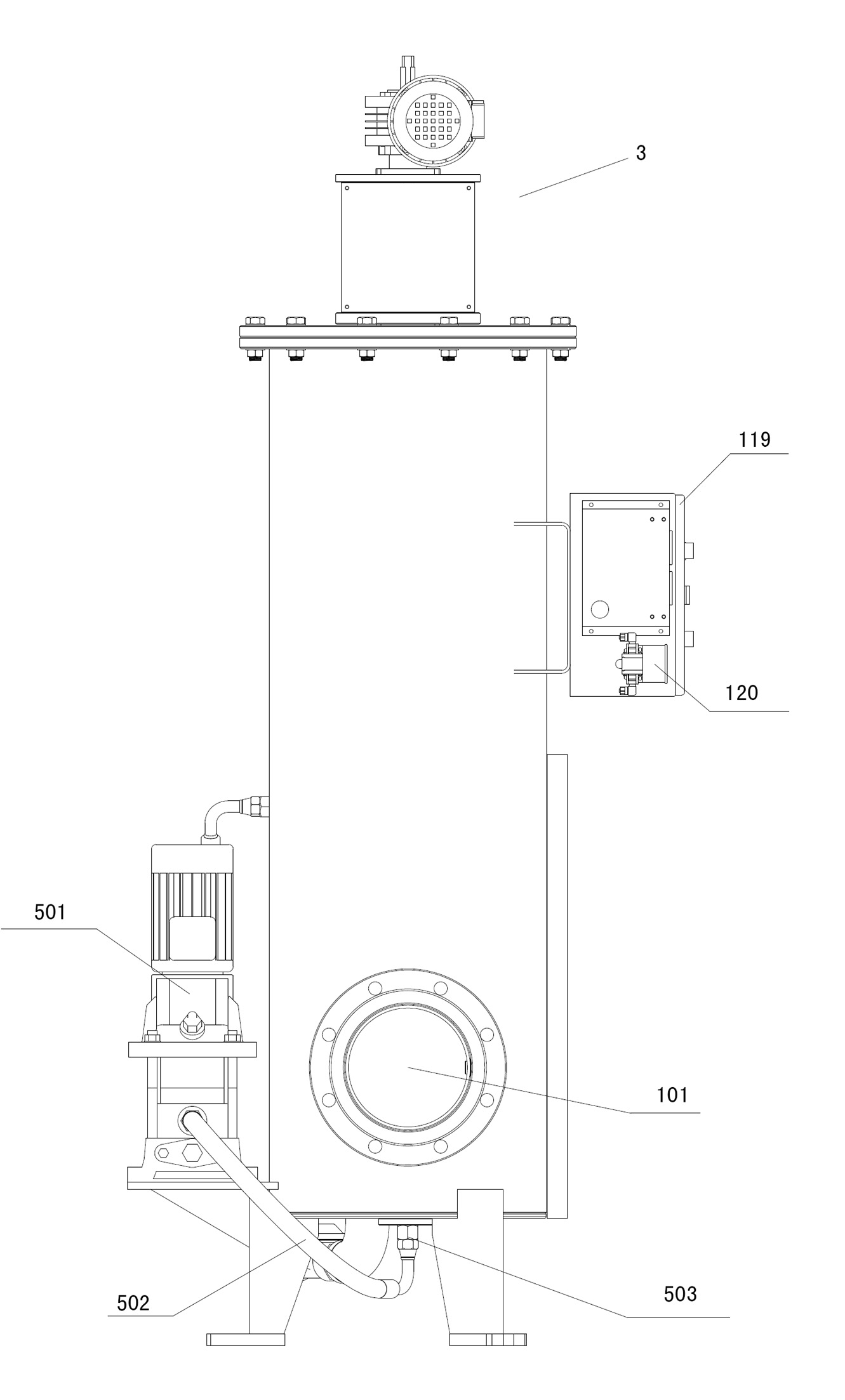

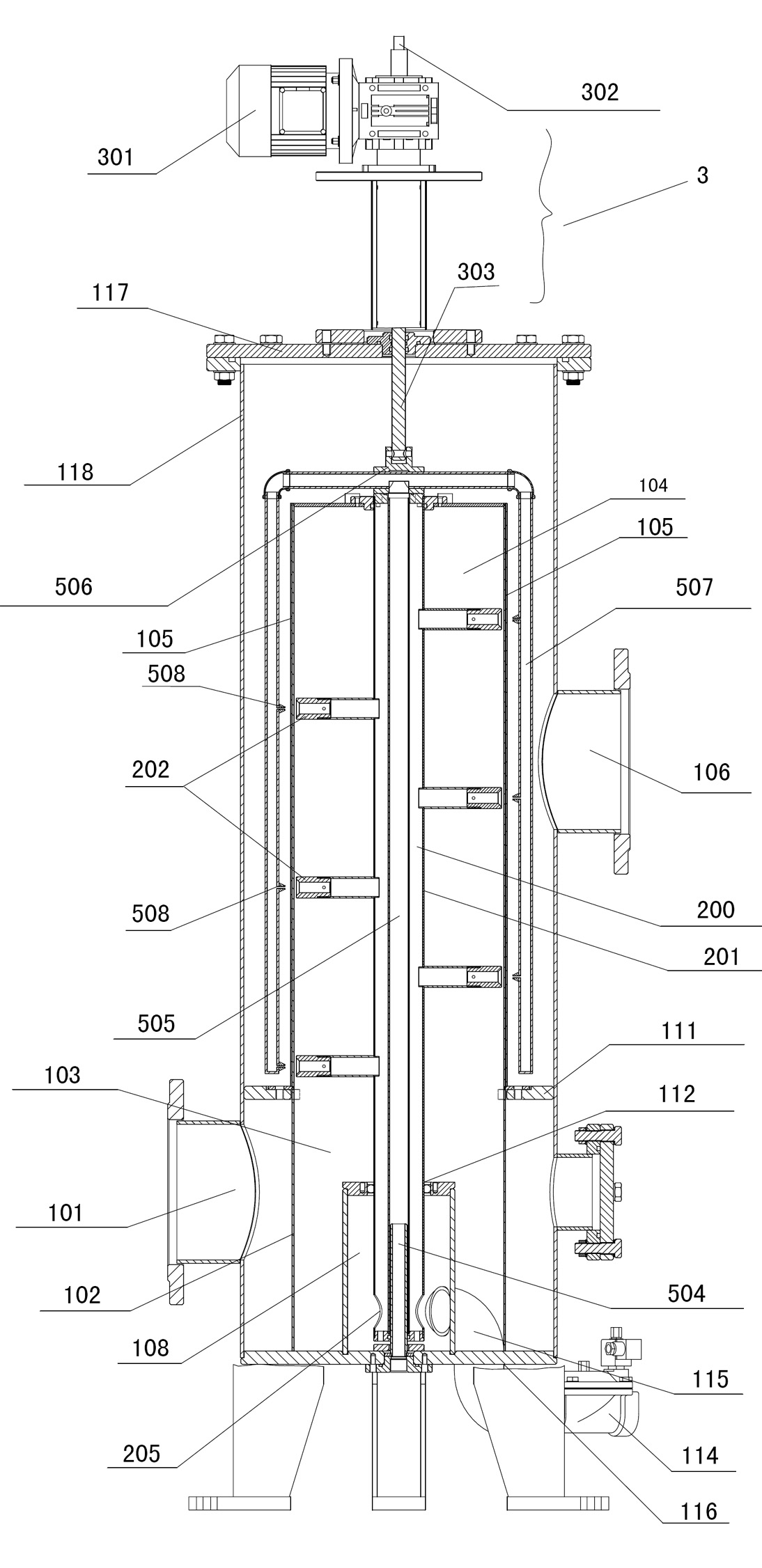

[0020] Please refer to figure 1 , figure 2 and image 3 The basic structure of the self-cleaning filter that can be backwashed on both sides of the present invention is the same as that of the prior art, mainly including a filter part, a dirt suction device assembly, and a backwash drive part. The filter part includes a water inlet 101, Coarse filter screen 102, coarse filter cavity 103, fine filter cavity 104, fine filter screen 105 and water outlet 106, raw water is introduced from water inlet, passes through coarse filter screen to coarse filter cavity, enters fine filter cavity from coarse filter cavity again, passes through It is drawn out from the water outlet after secondary filtration by the fine filter; the specific structure of this filter can be found in figure 1 and image 3 , 111 is the partition between the coarse filter chamber and the fine filter chamber, 112 is the partition between the coarse filter chamber and the sewage chamber, and these structural fea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com