Airshower chamber

An air shower and clean room technology, applied in the field of air shower, can solve the problems of poor product quality, influence, hidden dangers of experimental equipment and precision product quality control, etc., and achieve the best dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

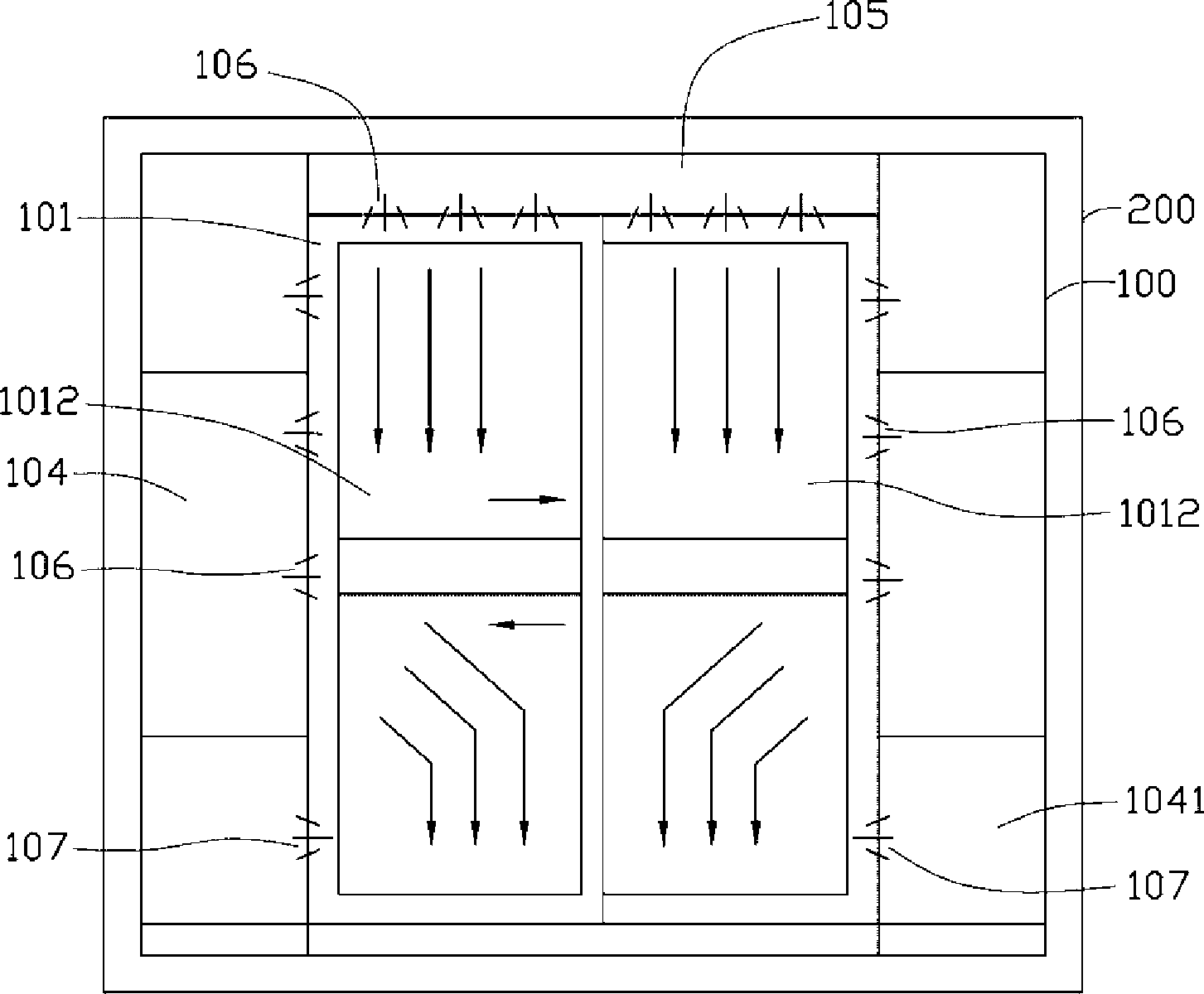

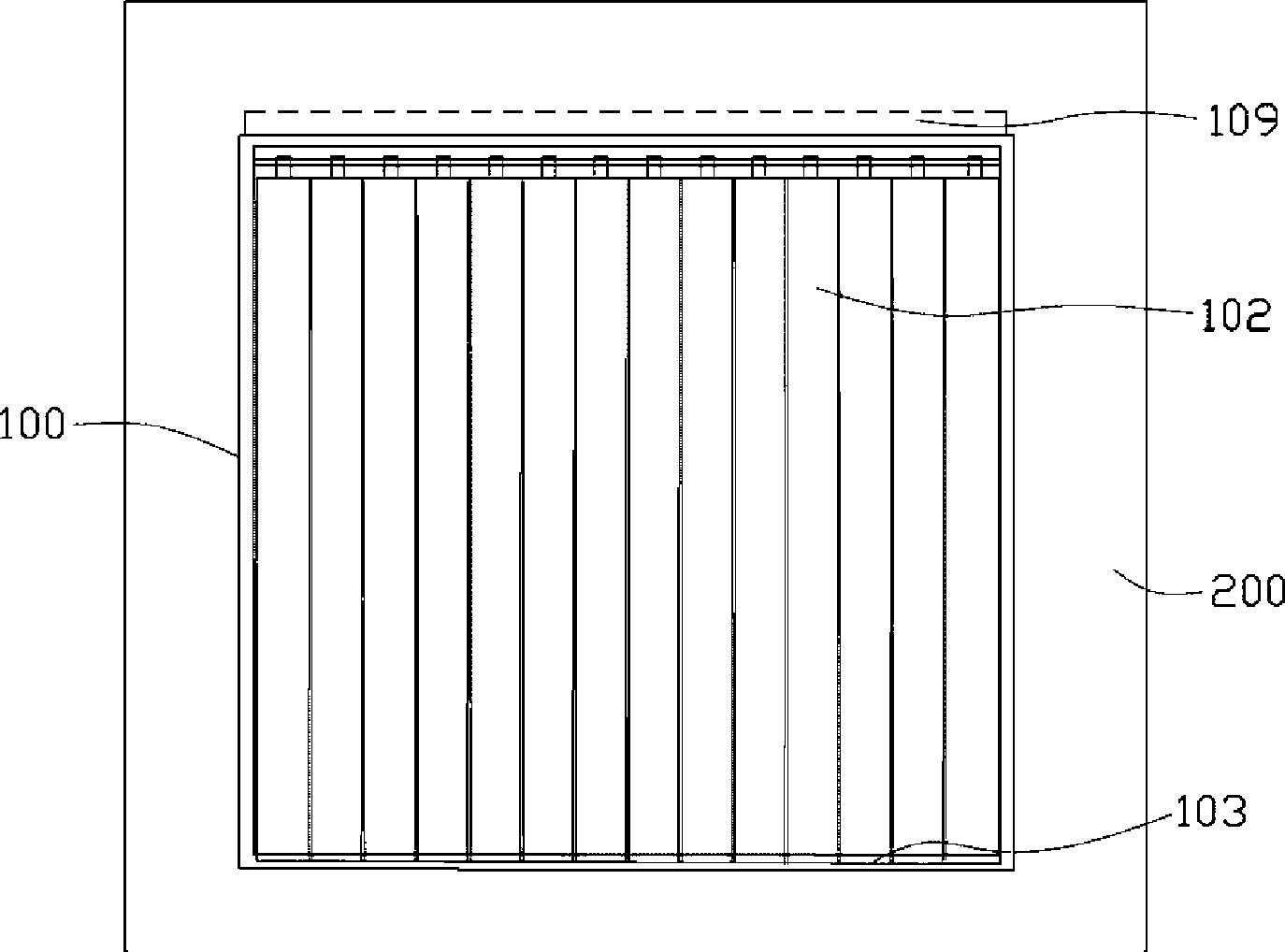

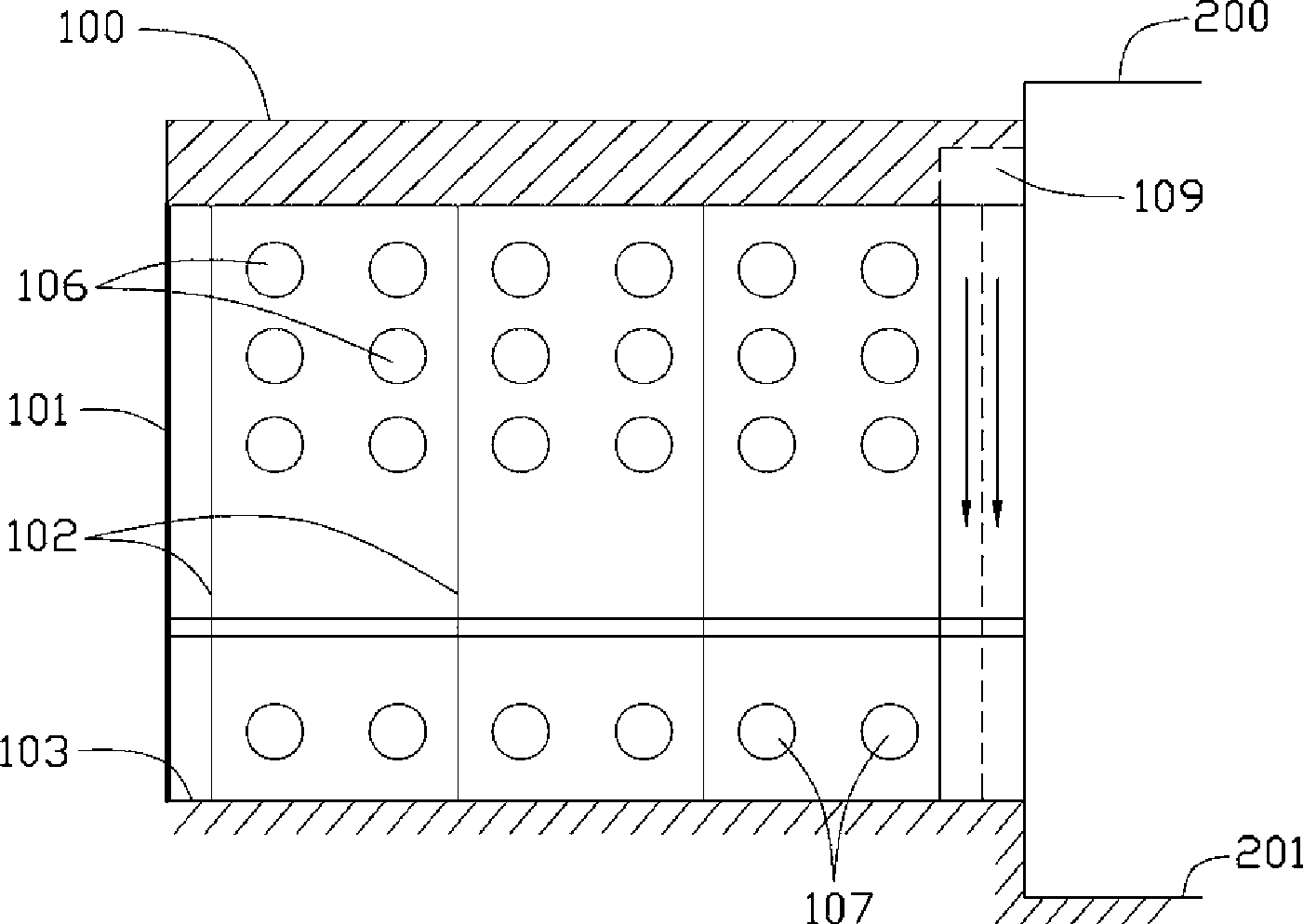

[0011] see figure 1 , figure 2 and image 3 , the preferred embodiment of the present invention provides an air shower room 100, the air shower room 100 is connected to the outside world through an air shower room inlet (not shown), and the air shower room 100 is connected to a clean room 200, And set at the entrance of the clean room 200, the clean room 200 has a clean room floor 201. The air shower room 100 includes an electronically controlled automatic door 101, several electrostatic curtains 102, an air shower room floor 103, an air shower room wall surface 104, an air shower room ceiling 105, several gas nozzles 106, several air outlet holes 107 and An air curtain 109. Wherein, an infrared sensor (not shown) is set on the wall 104 of the air shower near the electric control automatic door 101 inside the air shower 100, and the wall 104 of the air shower has a bottom 1041 of the wall of the air shower, which is dust-free The entrance of the air shower is the exit of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com