Automatic tea packaging machine

An automatic packaging machine and tea technology, which is applied in the directions of packaging, transportation and packaging, and types of packaging items, can solve the problems of inability to vacuumize dust and enter the human body, and achieve good dust removal effect, good preservation, and ensure clean and hygienic effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The content of the present invention will be described below in conjunction with specific embodiments.

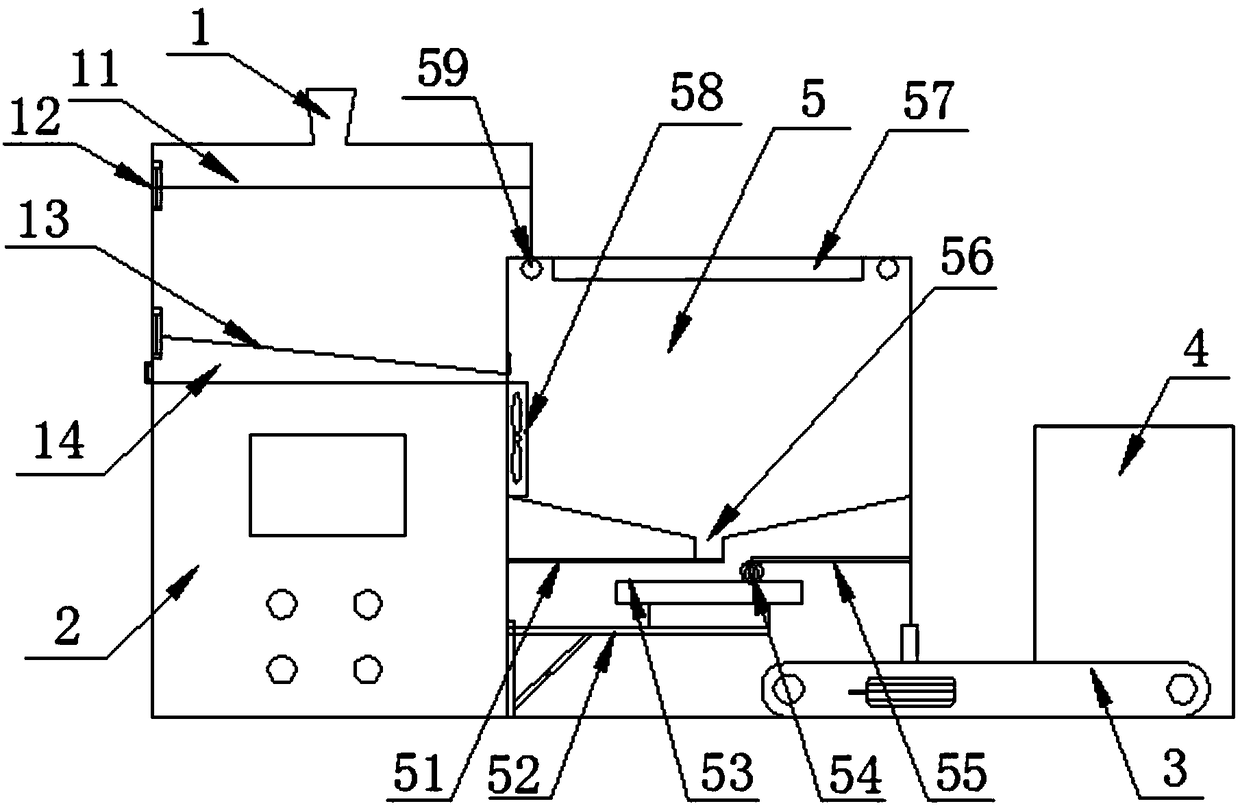

[0015] Such as figure 1 Shown is a structural schematic diagram of the automatic tea packaging machine of the present invention.

[0016] The high-efficiency tea automatic packaging mechanism of the present invention includes a feeding device, a dust removal room and a packaging device, the feeding device includes a feed port 1, and the dust removal room includes a primary dust removal room and a secondary Dust removal room 5, described packaging device comprises weighing sub-packaging device 53 and vacuum packaging machine 4; Described primary dust removal room comprises first dust removal vibrating screen 11 and second dust removal vibrating screen 13, and described first dust removal vibrating screen 11 is horizontal Arranged below the feed port 1, the second dust-removing vibrating screen 13 is obliquely arranged below the first dust-removing vibrating screen 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com