Dust collector with dust cleaning function

A technology of dust collector and function, applied in the field of dust collector with dust cleaning function, can solve the problems of the effect of cloth bag use, difficulty in ensuring filtration efficiency and effect, low dust removal quality, etc., to achieve obvious dust removal effect and avoid excessive dust suspension. , improve the filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

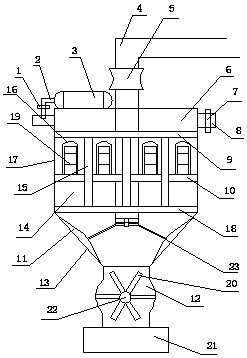

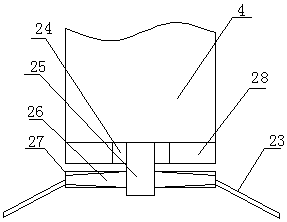

[0016] Such as Figure 1~2 As shown, a dust collector with dust removal function includes a dust collector 13, an air filter chamber 14, a flue gas input pipe 4, and a dust collector box 17, and the bottom of the dust collector box 17 is welded with a dust collector 13 , the bottom of the dust collector 13 is connected to the dust discharge chamber 12, the middle part of the dust collector box 17 is provided with a flue gas input pipe 4, the flue gas input pipe 4 extends into the dust collector 13, and the end of the flue gas input pipe 4 is provided with a support Frame 28, bearing 24 is arranged in the middle part of support frame 28, and bearing 24 is connected with rotating shaft 25, and rotating shaft 25 is connected with fan blade 26, and fan blade 26 periphery is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com