Sliding-type tool special for positioning clamp screw hole

A technology for locating wire clips and special tools, applied in manufacturing tools, workshop equipment, etc., can solve problems such as the deviation between the marked position and the actual position of the screw hole, the template cannot be directly fixed on the wire clip, and the template cannot be reused many times. Improve work efficiency, avoid reprocessing, and save resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

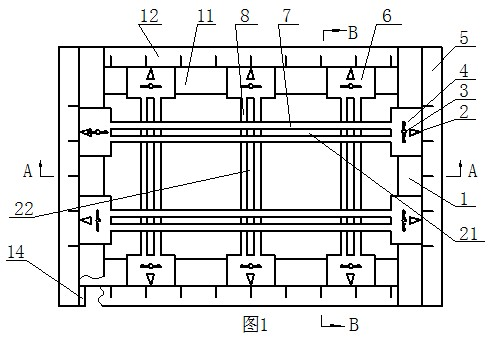

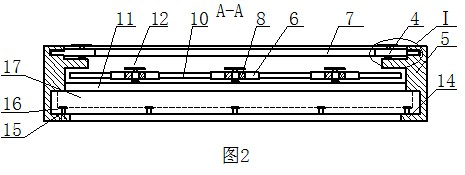

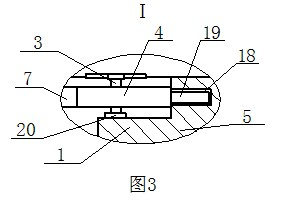

[0009] The special tool for the position of the screw hole of the sliding type positioning wire clamp according to the present invention includes a frame, such as figure 1 As shown, the frame is a square frame composed of two horizontal scales 12 up and down and two vertical scales 5 on the left and right. The surfaces of the vertical scales 5 and the horizontal scales 12 are all provided with scale marks 13, and the inner sides of each horizontal scale 12 A transverse movement chute 10 is provided, and a vertical movement chute 18 is provided on the inner side of each longitudinal scale 5; a transverse movement caliper 8 is installed between the two transverse scales 12, and a second through groove 22 is provided on the transverse movement caliper 8. The two ends of the moving caliper 8 are respectively provided with a traverse slider 6, and the two traverse sliders 6 are provided with a traverse guide block 9, and the two traverse guide blocks 9 are respectively connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com