Bumper mould for realizing standardized mould frame

A technology for bumpers and mold bases, which can be applied to household appliances, other household appliances, household components, etc., and can solve problems such as the inability to achieve mold interchangeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

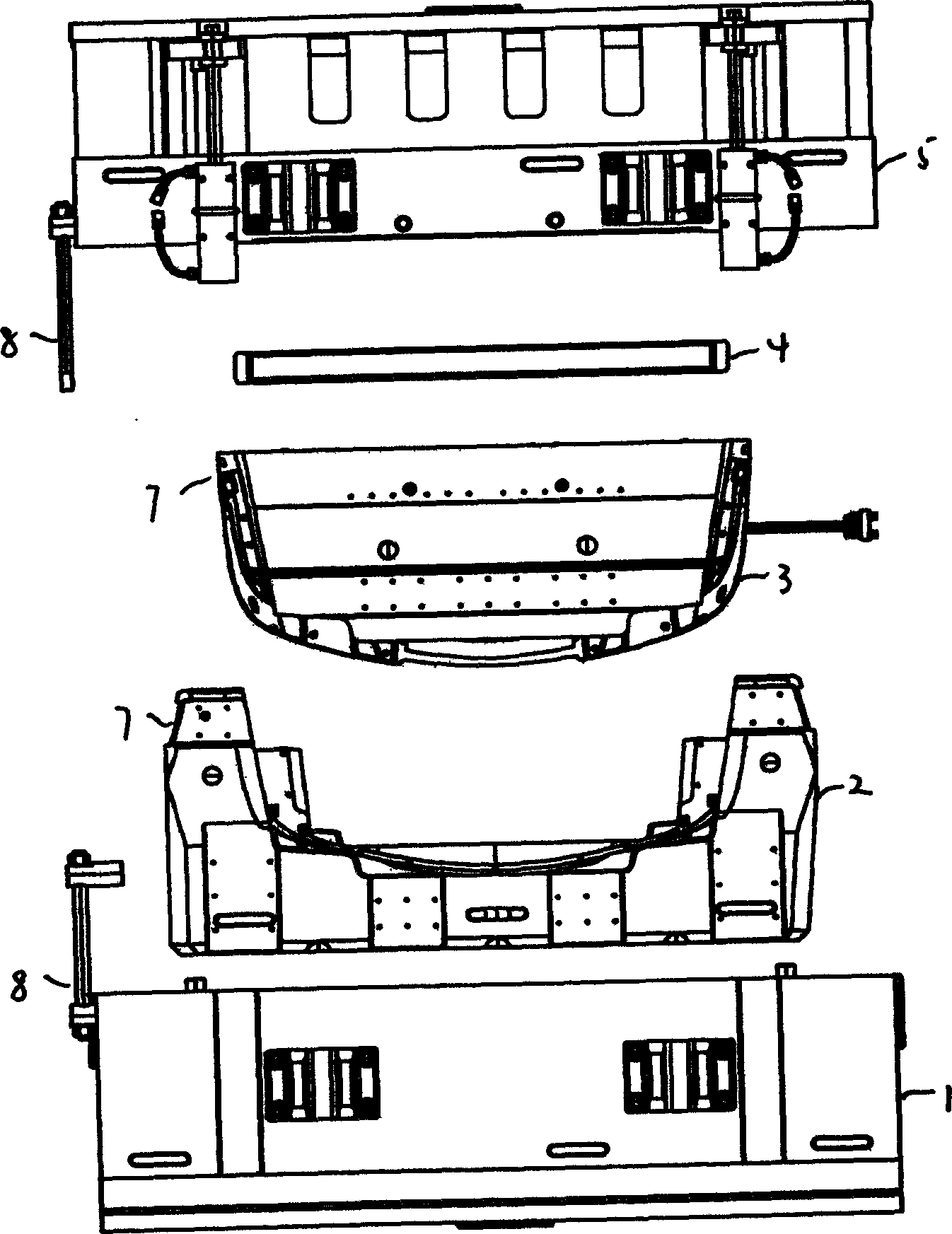

[0032] see figure 1 , the present invention realizes the bumper mold of standardized formwork, mainly is made up of standard formwork, cavity insert 2 (band core pulling), core insert 3 (band core pulling), thimble plate 4 and cooling system 7. The standard formwork is composed of a fixed mold standard formwork 1, a moving mold standard formwork 5, a guide system 6, a locking device 8 and a lifting device 9, etc.

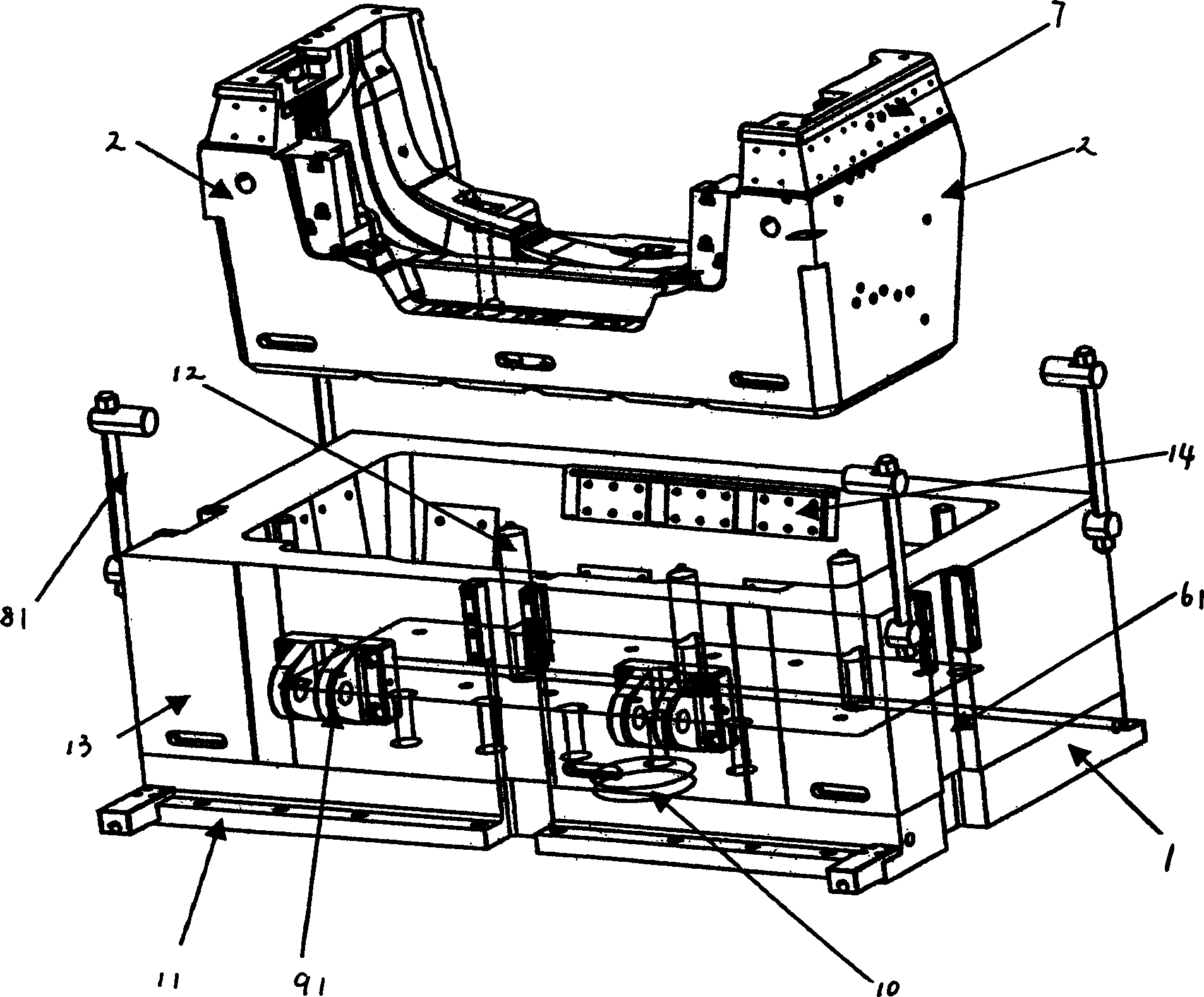

[0033] see figure 2 , the fixed mold standard formwork 1 is composed of a fixed mold bottom plate 11 , a runner system 12 and a fixed template 13 . The base plate 11, the runner system 12 and the fixed plate 13 constitute a complete assembly. The fixed mold standard mold base 1 and the cavity insert 2 (with core pulling) constitute the fixed mold part of the bumper mould. Fixed mold bottom plate 11 matches with injection molding machine. The runner system 12 is a necessary component applicable to different bumper products.

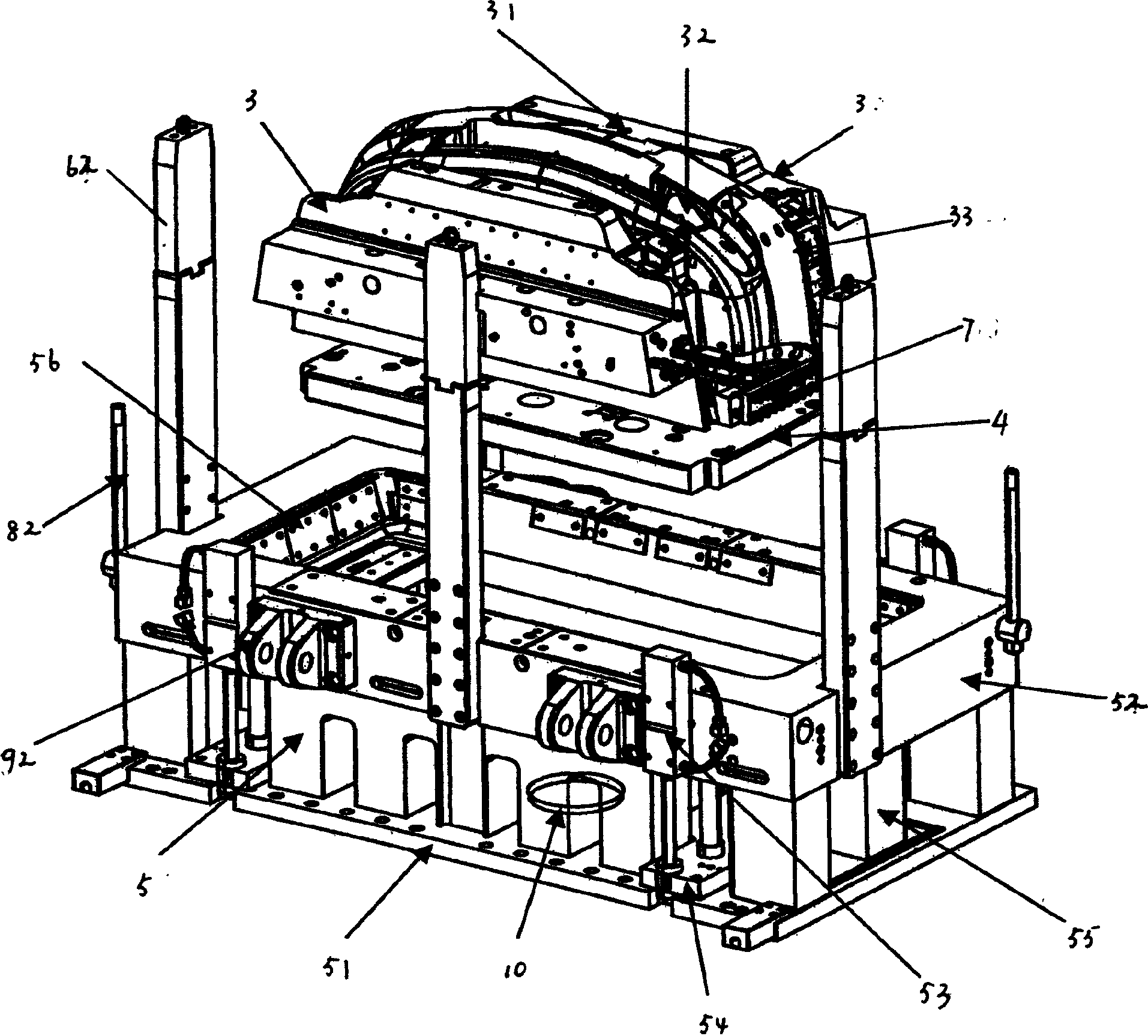

[0034] see image 3 , the movable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com