Method for carrying out alkali adding treatment, alkali refining and refining on crude oil through supergravity technology

An alkali treatment and super-gravity technology, applied in the direction of fat oil/fat refining, fat production, etc., can solve the problems of long semi-continuous treatment time, low production efficiency, large floor space, etc., and achieve flexible environmental adaptability and easy maintenance , easy operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

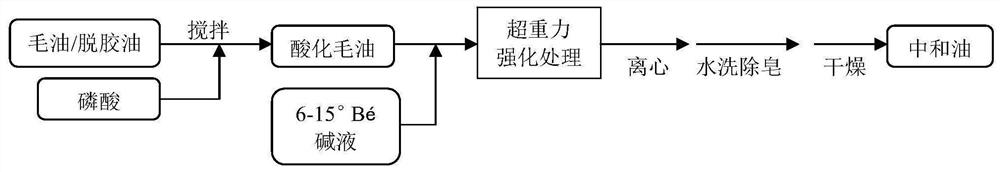

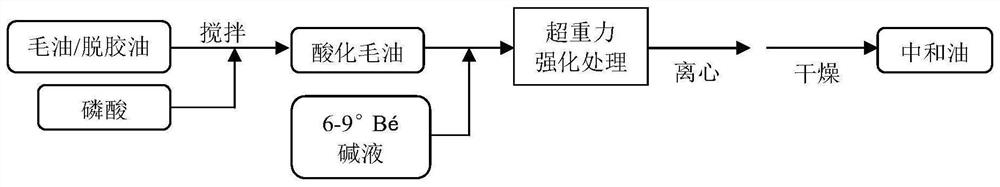

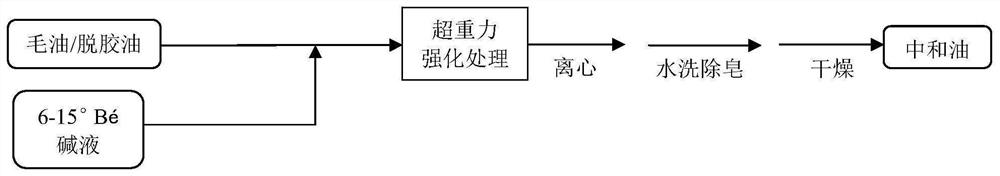

Method used

Image

Examples

Embodiment 1

[0043] The present embodiment adopts the following steps to carry out:

[0044] Step 1: Acidification

[0045] Take by weighing 200g crude oil, calculate the quality that adds phosphoric acid by following formula:

[0046]

[0047] Wherein M is the crude oil weight (kg), P is the non-hydratable phospholipid content (ppm), x is the excess acid (%), and C is the phosphoric acid concentration (%).

[0048] After adding acid at 75°C, stir at 1000 rpm for 40 min to complete the acidification step. At the same time, it is used as the initial condition for corresponding optimization.

[0049] Step 2: Alkali treatment

[0050] Calculate the mass of NaOH solution added according to the following formula:

[0051]

[0052] Wherein M is the weight of crude oil (kg), A is the acid value of crude oil (mg KOH / g), y is excess alkali (%), and C is NaOH concentration (%).

[0053] The alkali-adding treatment step of each embodiment is carried out in the mode of continuous feeding an...

Embodiment 2—15

[0060] Test procedure is identical with embodiment 1, and concrete process parameter and test result see table 1 below, and the parameter not listed in the table is all identical with embodiment 1, and the letter meaning and unit listed in table header are exactly the same as in embodiment 1:

[0061] Table 1

[0062]

Embodiment 16

[0063] Embodiment 16: Omit the impact of washing step on final product

[0064] Keep other conditions unchanged (62g of supergravity level, 6 Baume degrees of alkali concentration, 20% of excess acid, 10% of excess alkali, and 75°C of alkali refining temperature), the acid value 2.60mg KOH / g, the crude soybean oil of phosphorus content 430ppm carries out acidification step. The parameters of the final product obtained are shown in Table 2.

[0065] Table 2

[0066] Acid value mg KOH / g Phosphorus contentppm Experimental group 1 0.07 6.21 Experimental group 2 0.05 5.82 Experimental group 3 0.05 6.33

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com