High temperature alloy-titanium alloy bimetallic ring piece rolling forming method

A technology of superalloy and titanium alloy, applied in the direction of metal rolling, metal rolling, etc., can solve the problems of rolling failure, low production efficiency, many processes, etc., and achieve the effect of good size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0016] The main chemical element content (percentage by weight) of the GH4169 alloy is: C content≤0.08%, Cr content 17.0%~21.0%, Ni content 50.0%~55.0%, Co content≤1.0%, Mo content 2.80% %~3.30%, Al content 0.30%~0.70%, Ti content 0.75%~1.15%, Nb content 4.75%~5.50%, B content≤0.006%, Mg content≤0.01%, Mn content≤ 0.35%, Si content≤0.35%, P content≤0.015%, S content≤0.015%, Cu content≤0.30%, Ca content≤0.01%, Pb content≤0.0005%, Se content≤0.0003 %, the balance is Fe.

[0017] The main chemical element content (percentage by weight) of the TC4 alloy is: 5.5%-6.8% Al content, 3.5%-4.5% V content, 0.30% Fe content, 0.10% C content, 0.05% N content, The content of H is 0.015%, the content of O is 0.20%, and the balance is Ti.

[0018] The steps of this method are as follows:

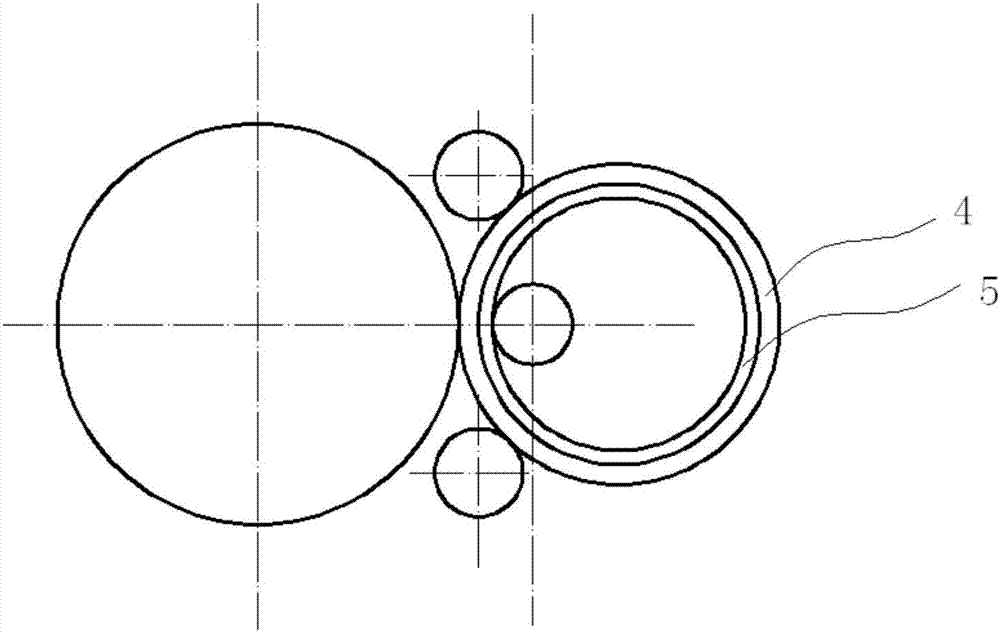

[0019] The GH4169 alloy and TC4 alloy are cut into bars according to certain specifications, and then processed into GH4169 alloy ring billet 4 and TC4 alloy ring billet 5 through upsetting, punching and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com