Glass waste and impurity recycling treatment system

A processing system and glass technology, which is applied in the direction of glass recycling, recycling technology, grain processing, etc., can solve the problems of poor crushing effect of the pulverizer, messy types, and danger to the staff, so as to achieve convenient handling and subsequent processing, and convenient re-use Good effect of utilization and crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] It should be noted that, the features in the various embodiments of the present invention may be combined with each other without explicit limitation or conflict. The present invention will be described in detail below with reference to the accompanying drawings and in conjunction with the embodiments.

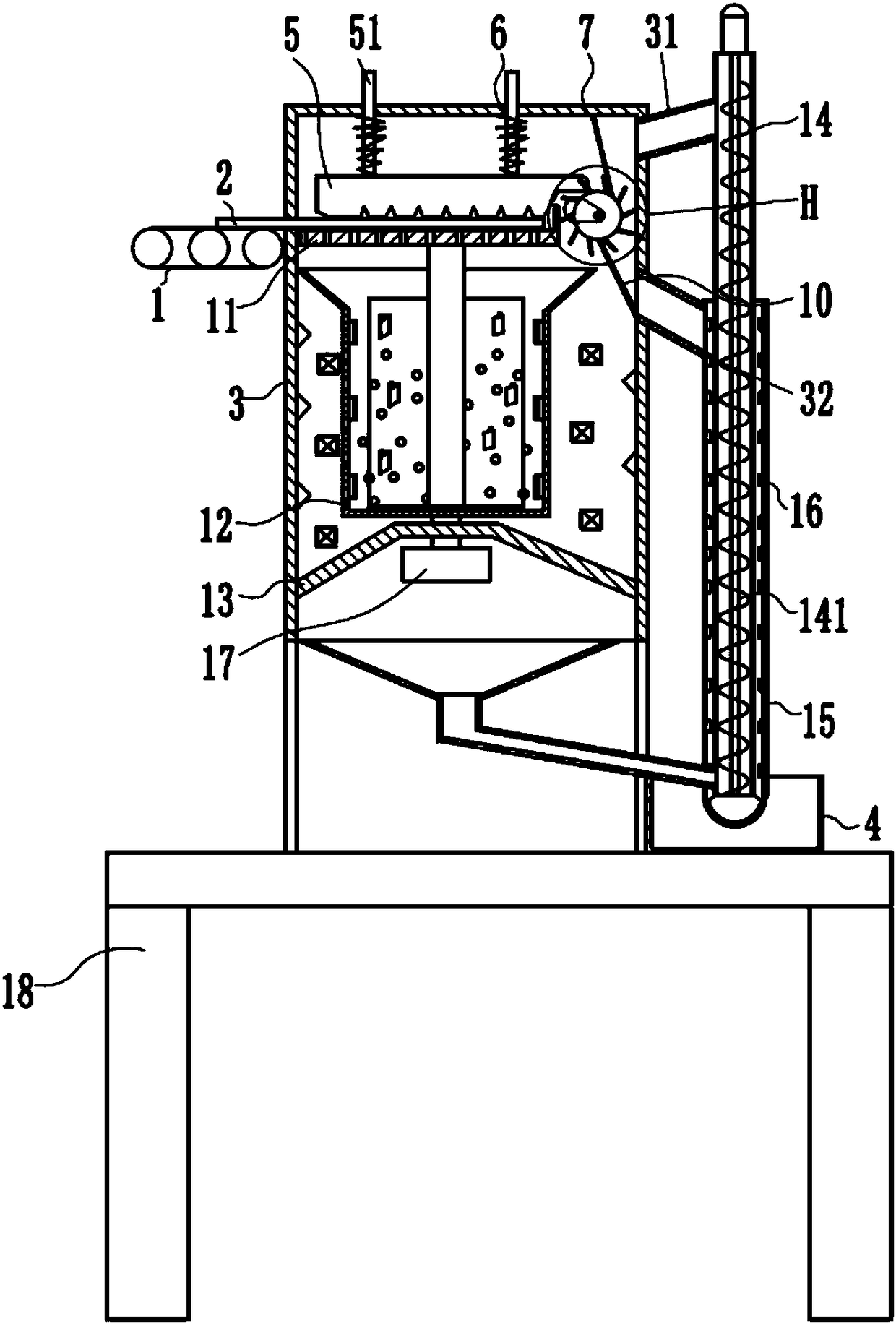

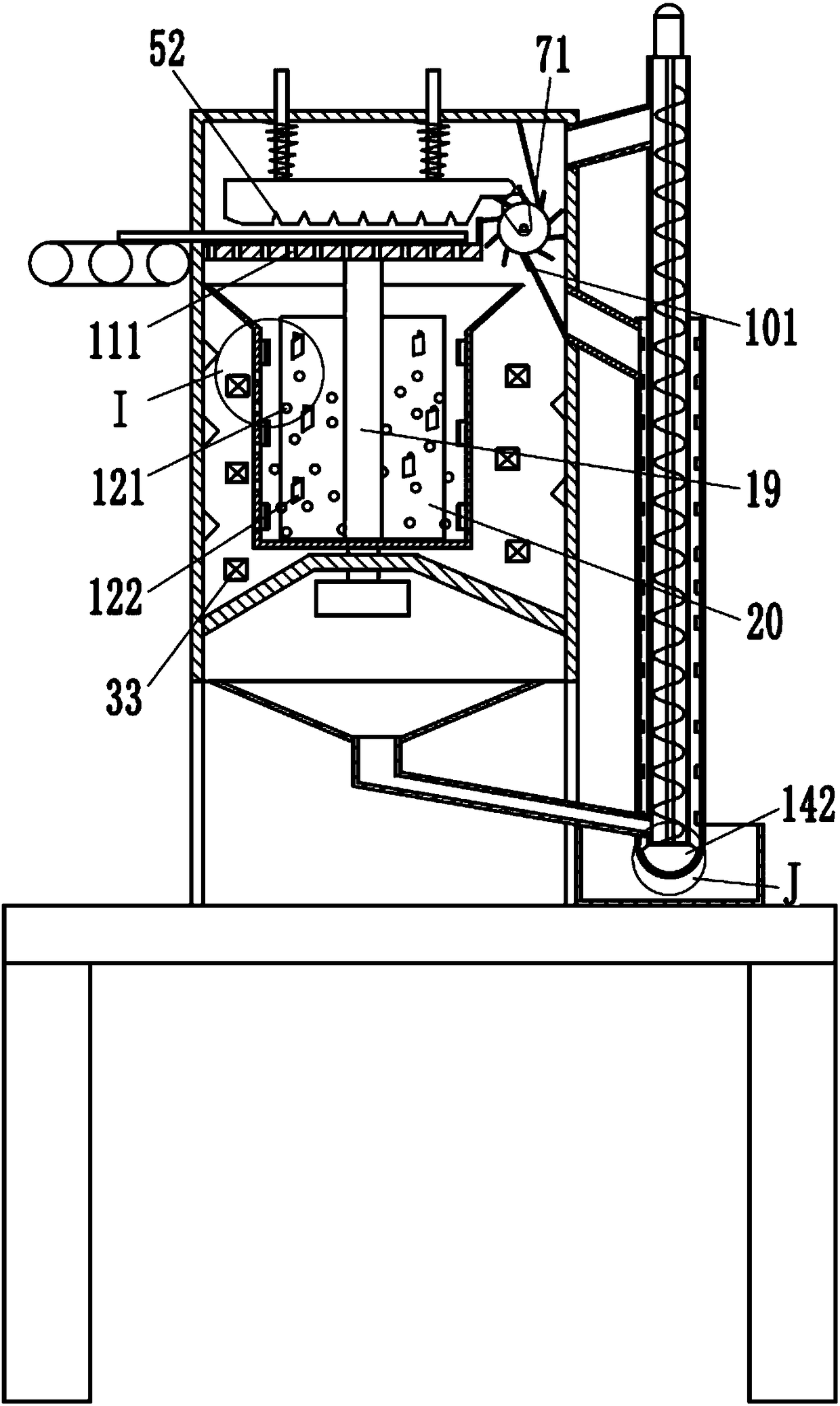

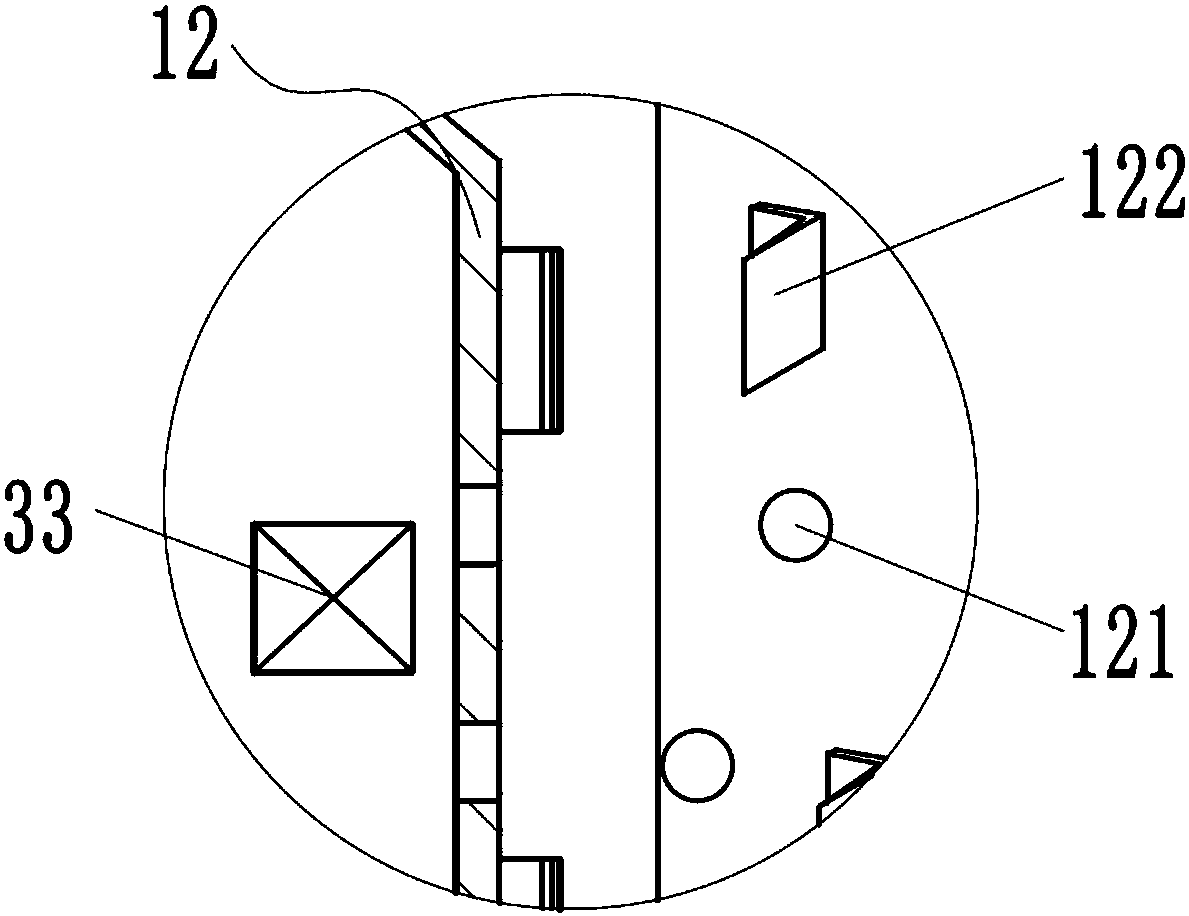

[0037] refer to Figure 1 to Figure 6 ,like figure 1 , figure 2 , image 3 and Figure 4The shown glass waste recycling treatment system includes: an outer crushing barrel 3 , a vibrating crushing device, an inner crushing barrel 12 , a spiral feeding device, a grinding device and a conveyor belt 1 . The vibratory crushing device includes a knocking hammer 5, a runner 8 and a cam 9. Several knocking blades 52 are arranged on the front of the knocking hammer 5, and the knocking blades 52 are used to knock the glass plate 2. crushing, several positioning shafts 51 are provided on the back of the percussion hammer 5, and the positioning shafts 51 are slidably arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com