Method for manufacturing circuit board with high thermal conductivity by oil printing method and circuit board with high thermal conductivity

A high thermal conductivity, circuit board technology, applied in the electrical field, can solve the problems of no further conduction of heat sink heat, damage to the circuit board electrical circuit, limited heat dissipation effect, etc., to achieve simple structure, avoid reprocessing, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

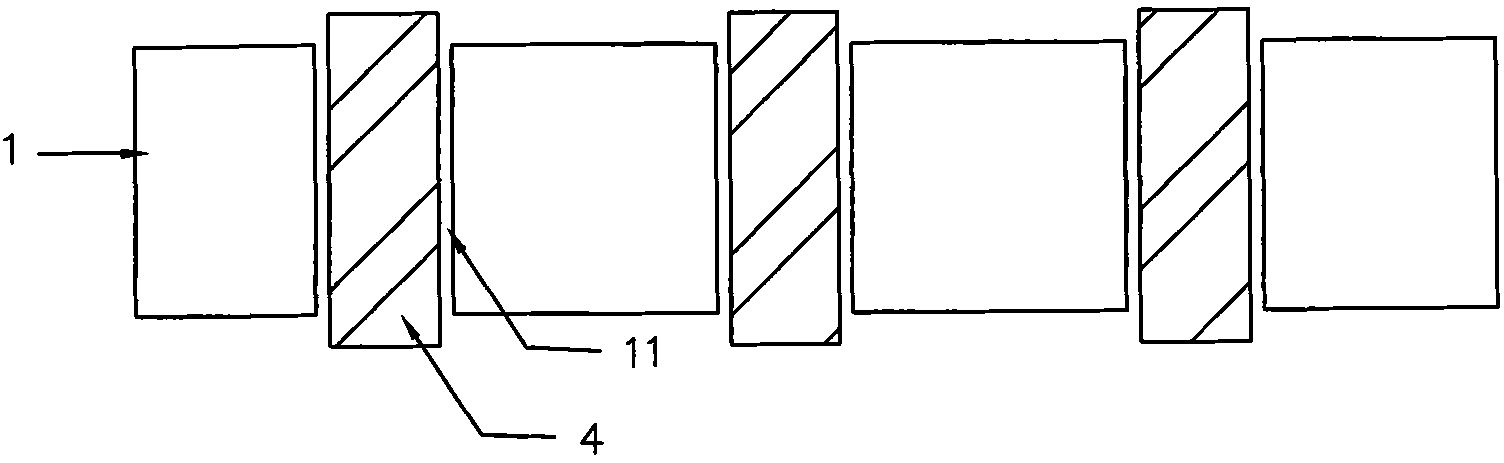

[0022] See Figure 1A-Figure 1F The method for making a circuit board with high thermal conductivity by the mimeograph method provided in this embodiment includes the following steps:

[0023] (1) Open some through holes 11 on the insulating substrate layer 1 (which can be FR4 sheet or BT sheet); (2) Make some metal heat conduction columns 4 that cooperate with the through holes; (3) Make the metal heat conduction columns 4 Put it into the through hole 11, and hot press and solidify; (4) The upper surface of the insulating substrate layer 1 mimeographs the conductive layer 2, and the lower surface mimeographs the heat-conducting layer 3, and the conductive layer 2 and the heat-conducting layer 3 are made of silver oil, copper oil or carbon (5) etching excess conductive material on the upper surface of the insulating substrate layer 1 to form electrical connection lines and a number of pads 22 ( Figure 1E Only pads are shown in ); the method provided by this embodiment may fur...

Embodiment 1

[0025] The high thermal conductivity circuit board that embodiment 1 makes is as Figure 1F As shown, it includes: an insulating substrate layer 1, a mimeograph conductive layer 2 located on the upper surface of the insulating substrate layer, a mimeograph thermally conductive layer 3 located on the lower surface of the insulating substrate layer, and a metal thermally conductive column 4; A through hole 11 is opened at the place where the heating element is set; the metal heat conduction column 4 is arranged in the through hole 11, and its upper end is used for thermal conduction cooperation with a preset heating element (not shown in the figure), and the lower end is for thermal conduction cooperation with the mimeograph heat conduction layer 3 . It includes an insulating base material layer 1, an electrical circuit layer on the upper surface of the insulating base material layer, a mimeograph heat-conducting layer 3 on the lower surface of the insulating base material layer,...

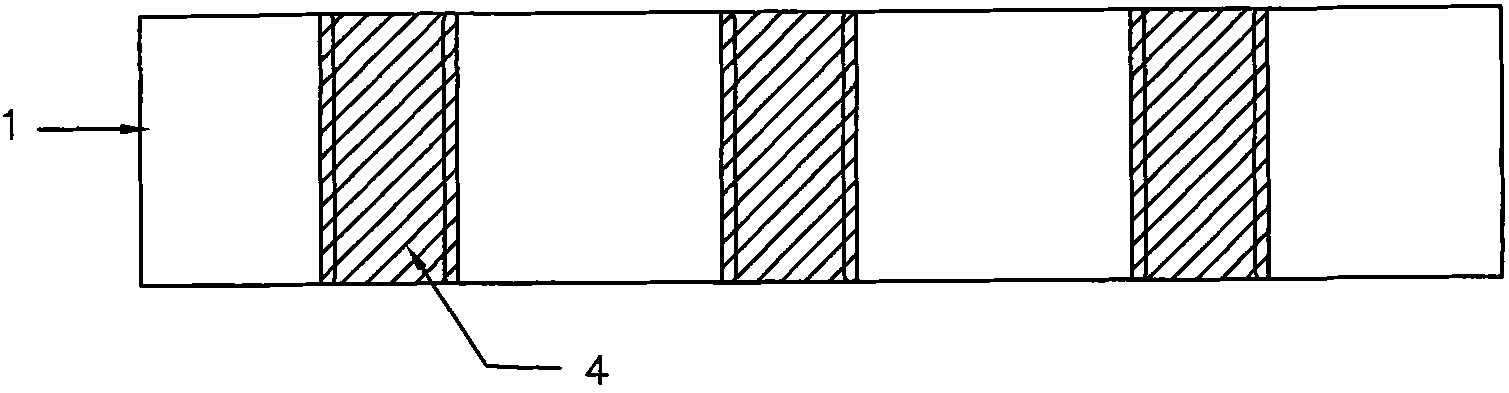

Embodiment 2

[0027] See Figure 2A-Figure 2F , the method for making a high thermal conductivity circuit board provided by this embodiment includes the following steps:

[0028] (1) Provide an insulating substrate layer 1 (which can be FR4 sheet or BT sheet), and attach a metal heat conducting layer 3 on the lower surface of the insulating substrate layer 1 to form a sheet with a metal layer on one side; (2) A number of through holes 11 are opened on the sheet with a metal layer; (3) a number of metal heat conduction columns 4 matching with the through holes are manufactured; (4) metal heat conduction columns 4 are placed in the through holes 11, hot-pressed and solidified; (5) Conductive layer 2 is mimeographed on the upper surface of insulating base material layer 1, and conductive layer 2 is materials such as silver oil, copper oil or carbon oil; Disc 22 ( Figure 2E Only pads are shown in ); the method provided by this embodiment may further include step (7): selectively plating elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com