Short-hole-channel ordered mesoporous silica-sulfur-indium-zinc composite photocatalyst as well as preparation method and application thereof

A mesoporous silica, short pore technology, applied in physical/chemical process catalysts, chemical instruments and methods, silicon compounds, etc., to achieve the effects of enhanced absorption and utilization, improved adsorption, and easy mass transfer and diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

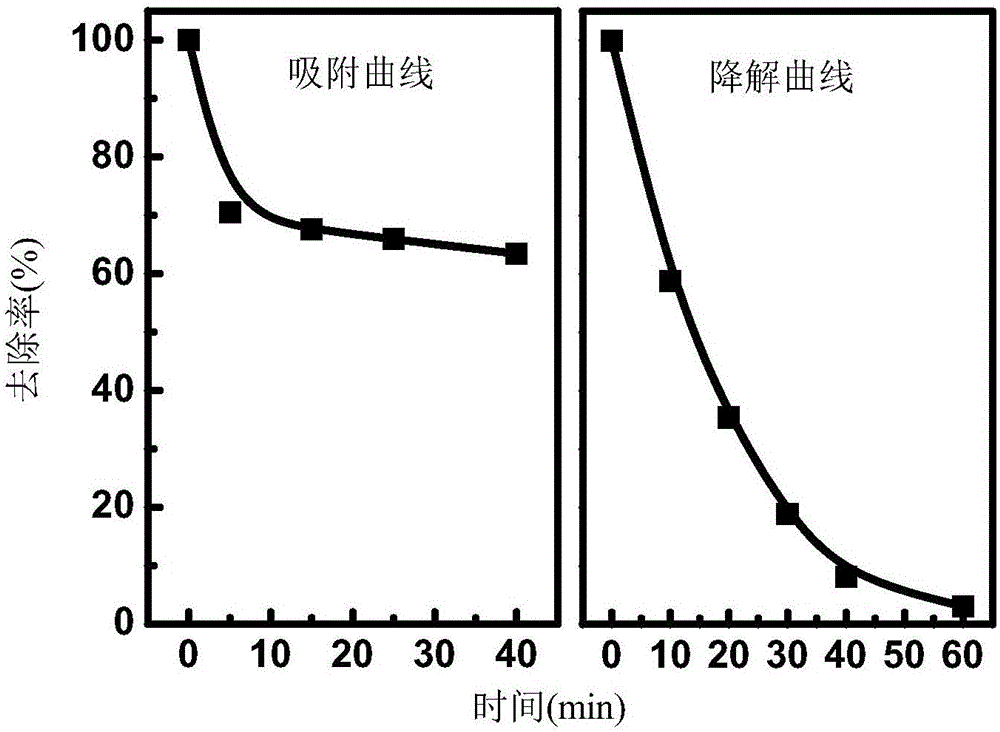

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. Preparation:

[0031] S1. Add 0.1g of polyethylene glycol to 6mL of water and concentrated hydrochloric acid solution with a volume ratio of 10:1, and stir at 90°C for 24h to obtain a clear solution;

[0032] S2. Mix 10mL tetraethyl orthosilicate, 50mgZrOCl 2 , 20 mg of zinc chloride, 60 mg of indium chloride and 30 mg of thiourea were slowly added to the clear solution obtained in step S1 in sequence, and stirred at 30° C. for 2 hours to obtain a white turbid solution;

[0033] S3. Put the white turbid solution obtained in step S2 into a 25mL polytetrafluoroethylene tank, and conduct a hydrothermal reaction at 60°C for 72h. After cooling in the polytetrafluoroethylene tank, collect the precipitate, rinse the precipitate with 50mL of water, wash The final precipitate was dried at 50°C for 36 hours to obtain short-channel ordered mesoporous silica;

[0034] S4. Mix the short-channel ordered mesoporous silica obtained in S3 with methanol at a ratio of 0.1mg / mL, ultra...

Embodiment 2

[0037]S1. Add 10g of polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer to 100mL of water and concentrated hydrochloric acid solution with a volume ratio of 1:1, and stir at 30°C for 24h to obtain clear solution;

[0038] S2. Mix 0.1mL tetraethyl orthosilicate, 500mgZrOCl 2 , 200 mg of zinc nitrate, 400 mg of indium nitrate and 30 mg of urea were slowly added to the clear solution obtained in step S1 in sequence, and stirred at 90° C. for 72 hours to obtain a white turbid solution;

[0039] S3. Put the white turbid solution obtained in step S2 into a 200mL polytetrafluoroethylene tank, and conduct a hydrothermal reaction at 250°C for 2 hours. After cooling in the polytetrafluoroethylene tank, collect the precipitate, wash the precipitate with 2000mL water, wash The final precipitate was dried at 180°C for 1 hour to obtain short-channel ordered mesoporous silica;

[0040] S4. Mix the short-channel ordered mesoporous silica obtained in step S3 with et...

Embodiment 3

[0042] S1. Add 5g of cetyltrimethylammonium bromide to 80mL of water and concentrated hydrochloric acid solution with a volume ratio of 5:1, and stir at 50°C for 6h to obtain a clear solution;

[0043] S2. Mix 2mL tetraethyl orthosilicate, 100mgZrOCl 2 , 150 mg of zinc sulfate, 200 mg of indium sulfate and 190 mg of thioacetamide were slowly added to the clear solution obtained in step S1 in sequence, and stirred at 50° C. for 12 hours to obtain a white turbid solution;

[0044] S3. Put the white turbid solution obtained in step S2 into a 100mL polytetrafluoroethylene tank, and conduct a hydrothermal reaction at 120°C for 18 hours. After cooling in the polytetrafluoroethylene tank, collect the precipitate, wash the precipitate with 1000mL water, The final precipitate was dried at 100°C for 8 hours to obtain short-channel ordered mesoporous silica;

[0045] S4. Mix the short-channel ordered mesoporous silica obtained in step S3 with ethanol at a ratio of 0.5 mg / mL, ultrasonica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com