Method for preparing water-soluble lutein

A lutein and water-soluble technology, which is applied in the field of preparing water-soluble lutein, can solve the problems of reducing the content of all-trans isomers, affecting the biological activity of products, and reducing the quality of lutein, so as to ensure water solubility and stability Improve and avoid the effect of secondary reprocessing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

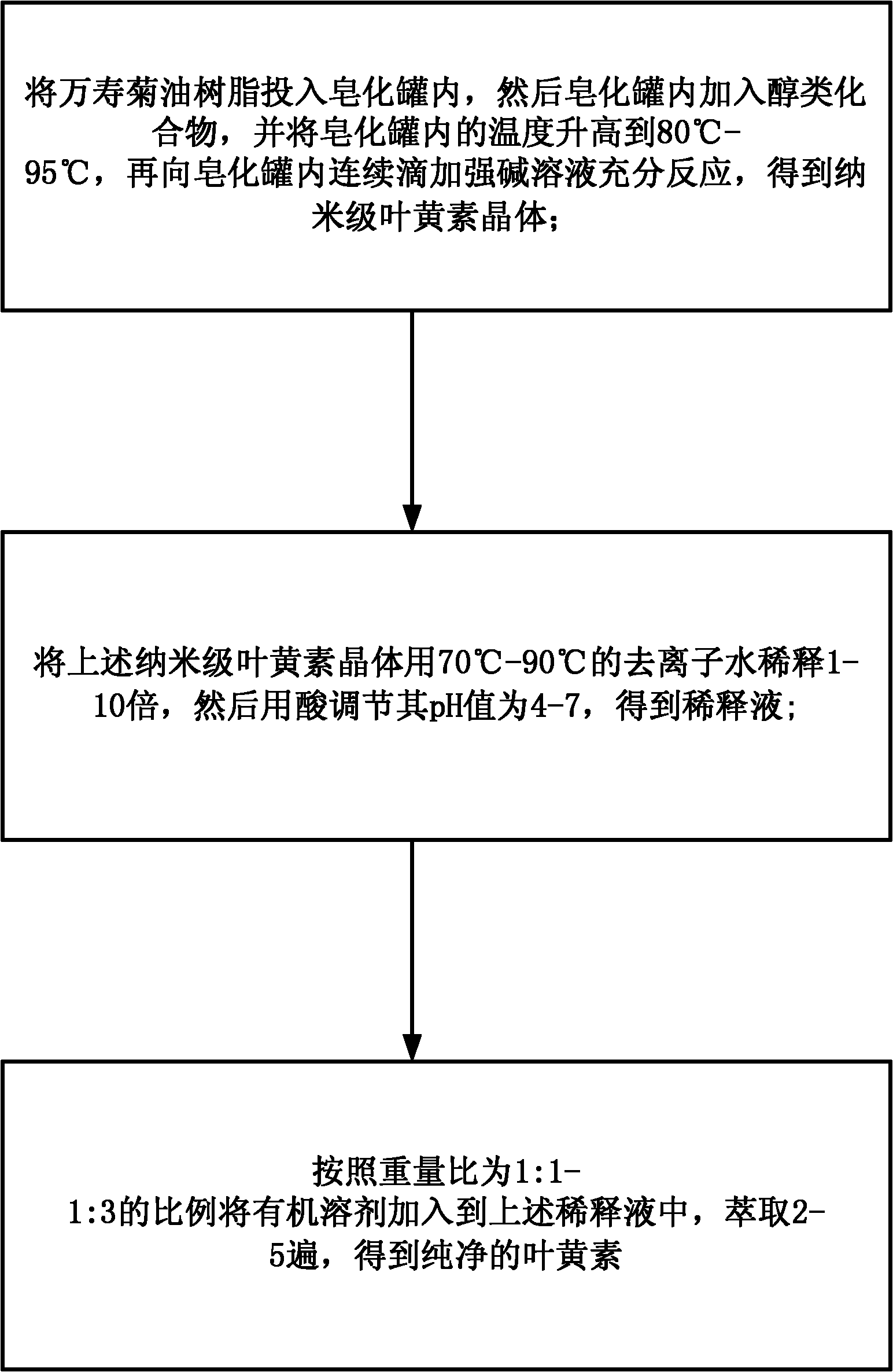

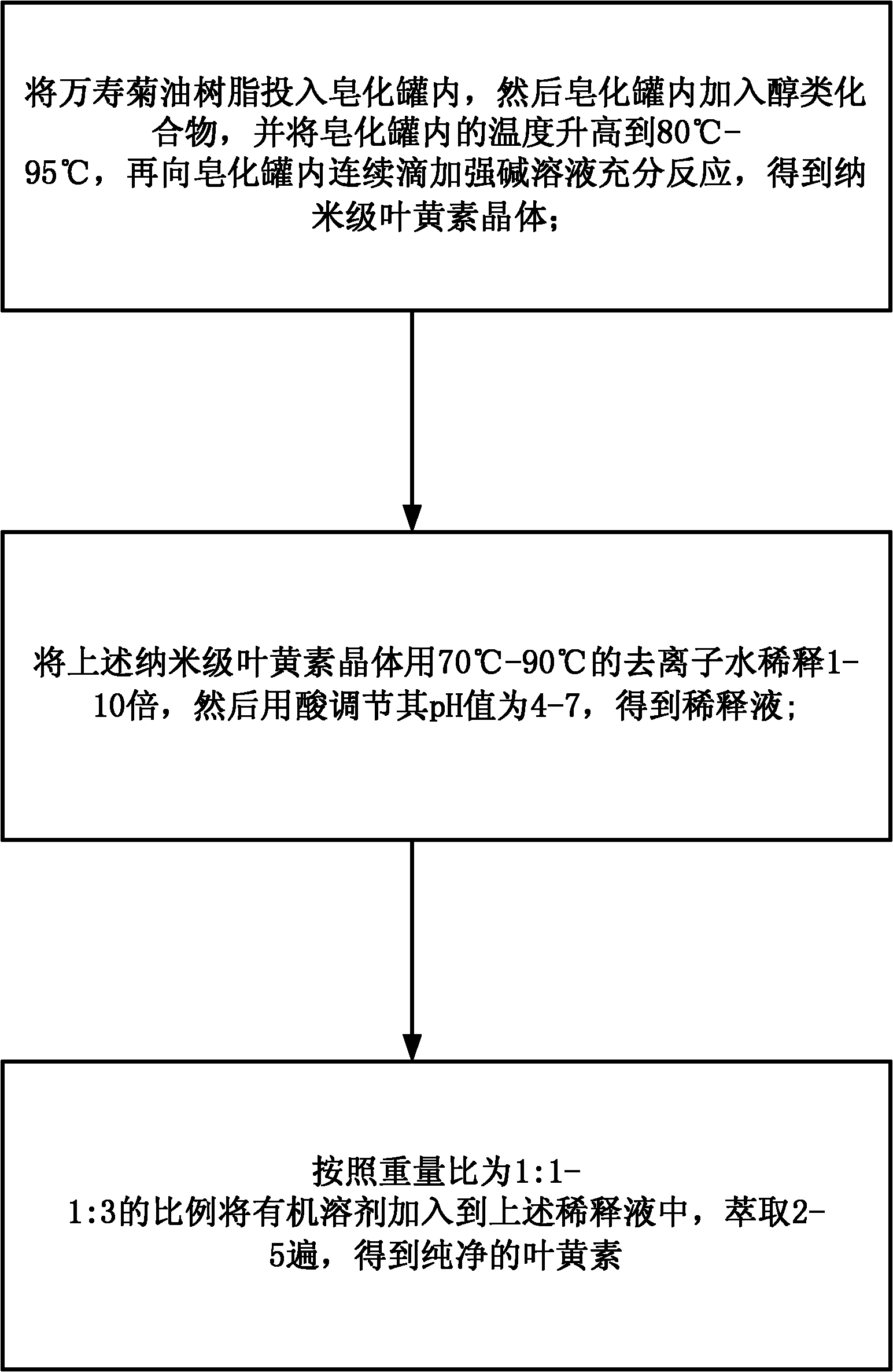

Method used

Image

Examples

Embodiment 1

[0042] Take 100g of marigold oleoresin with a content of 130g / kg, put it into a saponification tank, add 10g of glycerin, raise the temperature to 80°C, and keep the stirring speed at 150rpm, continuously add 34ml of KOH aqueous solution with a concentration of 10mol / L for 1 hour, and saponify After 4 hours, then add 1000g of deionized water at 80°C, add 110g of hydrochloric acid with a mass concentration of 10%, and make the pH value 5.8, then add 1100g of n-hexane for extraction, extract 3 times, and add 2g of diluent after extraction Sodium isoVC and 8g Tween-80; then 50g of soluble starch was dissolved in 300g of deionized water at 80°C for 30 minutes, then 30g of sucrose was added to dissolve, cooled to 45°C to obtain a diluent for use. The dilution and the wall material solution were mixed twice in a high-shear homogeneous emulsifier, and then the water was removed by spray drying to finally obtain an aqueous solution lutein powder with a content of 105.3g / kg and a weight...

Embodiment 2

[0044] Take 50 g of marigold oleoresin with a content of 145 g / kg, put it into a saponification tank, add 7.5 g of propylene glycol, raise the temperature to 85° C., and keep the stirring speed at 100 rpm, and continuously drop 17 ml of NaOH aqueous solution with a concentration of 10 mol / L for 1 hour. After 4 hours of saponification time, add 300g of deionized water at 85°C, add 102g of sulfuric acid with a mass concentration of 10%, and make the pH value 4.0, then add 1040g of 6# solvent oil for extraction, extract 4 times, and dilute the diluted solution after extraction , add 4.6g of natural VE and 5.7g of Span-80; dissolve 55g of soluble starch in 350g of deionized water at 80°C for 30 minutes, then add 20g of glucose to dissolve, cool to 45°C to obtain a diluted solution for use. The diluent and the wall material solution are mixed twice in a high-shear homogeneous emulsifier, and then the water is removed by spray drying to finally obtain an aqueous solution lutein powde...

Embodiment 3

[0046] Take 150g of marigold oleoresin with a content of 100g / kg, put it into a saponification tank, add 7.5g of mannitol, raise the temperature to 95°C, and keep the stirring speed at 100rpm, and continuously add 51ml of NaOH aqueous solution with a concentration of 10mol / L for 1 hour After 4 hours of saponification time, add 150g of deionized water at 95°C, add 185g of phosphoric acid with a mass concentration of 10%, and make the pH value 6.0, then add 1200g of petroleum ether for extraction, extract 5 times, and add the diluent after extraction to 5.24g of rosemary and 8.74g of sucrose ester; 30g of soluble starch was dissolved in 90g of deionized water at 80°C for 30 minutes, then 18.5g of β-cyclodextrin was added to dissolve, cooled to 45°C to obtain a diluted solution for use. The diluent and the wall material solution are mixed twice in a high-shear homogeneous emulsifier, and then the water is removed by spray drying to finally obtain an aqueous solution lutein powder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com