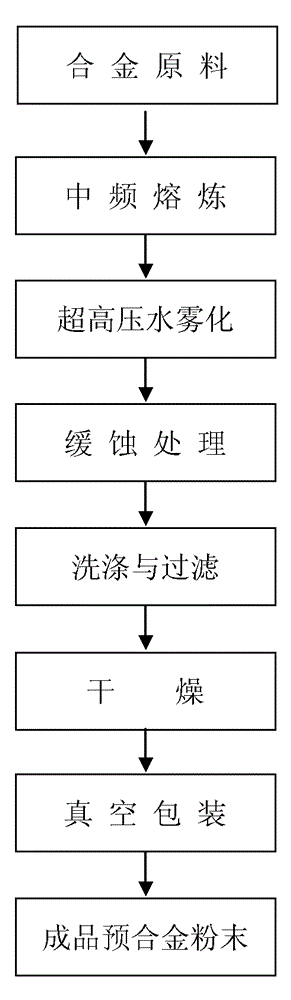

Method for preparing prealloy powder for low-oxygen-content micro-diamond product and using ultrahigh-pressure water atomization

A technology of pre-alloyed powder and low oxygen content is applied in the field of ultra-high pressure water atomization to prepare pre-alloyed powder for fine diamond products with low oxygen content. Eliminate the effect of component segregation and uniformity of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

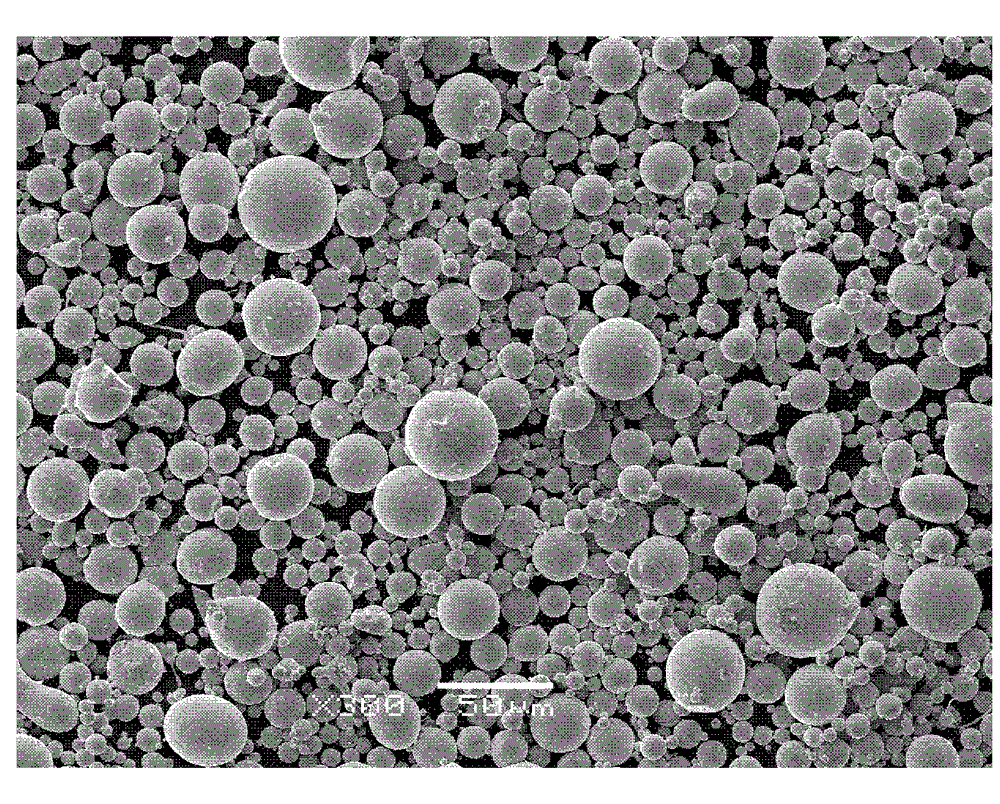

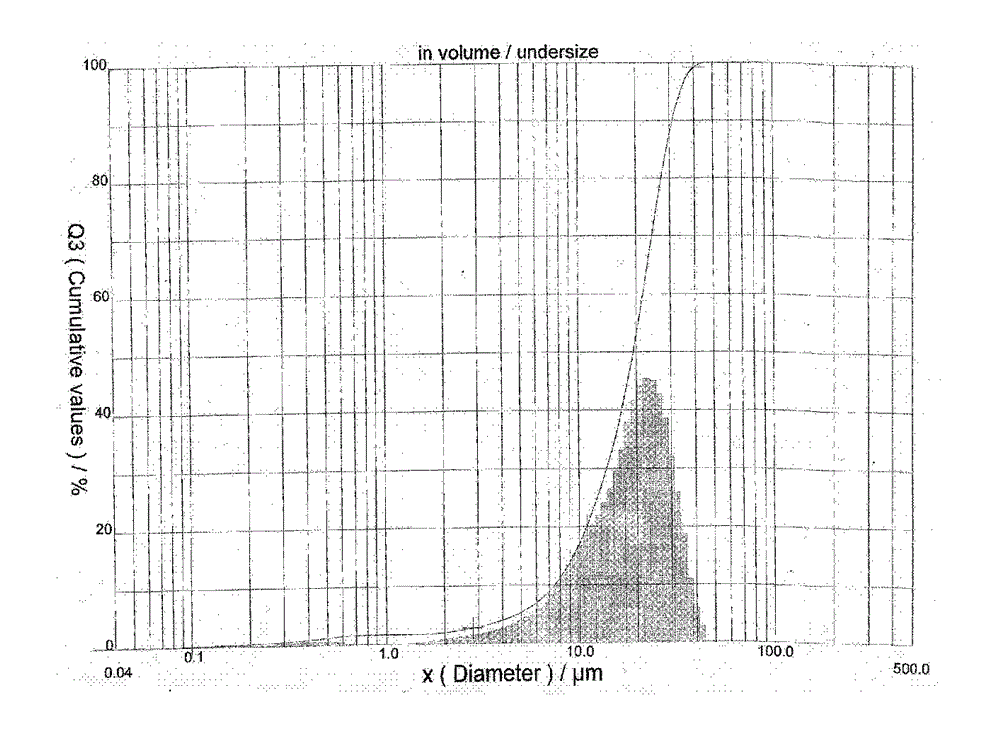

[0026] By weight percentage, the ingredients are Cu: 60%, Sn: 5%, Zn: 5%, Fe: 24%, Ti: 2%, Cr: 2%, Ce: 2%. Weigh 100 kg, put it into an intermediate frequency melting furnace to raise the temperature, and wait until the alloy raw material is melted and overheated at 150°C. Pour the molten metal into the leaky crucible, when the molten metal passes through the ceramic leakage hole at the bottom of the leaky bag and flows through the atomizing nozzle, control the jet water pressure: 55-60MPa, and the ratio of water flow to metal flow: 5.0-5.2 , the process cooling rate is: 10 4 ~10 5 K / s, the swirl angle range of the water jet is: 0.60~0.65rad, the liquid metal is crushed into small droplets by the ultra-high pressure water flow ejected from the nozzle, and then the pre-alloyed droplets are solidified into powder in the water of the atomization collection bucket. After being treated with TZYJ corrosion inhibitor with a concentration of 0.4%, the powder is dried at a temperatur...

Embodiment 2

[0029] In terms of weight percentage, the ingredients are Cu: 30%, Fe: 55%, Sn: 6%, Zn: 6%. Ce: 3%, weighing 100 kg, adding to the intermediate frequency melting furnace to raise the temperature, until the alloy raw materials are melted and overheated at 80-100°C. Pour the molten metal into the leaky crucible. When the molten metal passes through the ceramic leak hole at the bottom of the leaky bag and flows through the atomizing nozzle, control the jet water pressure: 65~70MPa, and the ratio of water flow to metal flow: 5.4~5.5 , the process cooling rate is: 10 4 ~10 6 K / s, the swirling angle range of the water jet is: 0.40~0.45rad, the liquid metal is crushed into small droplets by the ultra-high pressure water flow ejected from the nozzle, and then the pre-alloyed droplets are solidified into powder in the water of the atomization collection bucket. After being treated with TZYJ corrosion inhibitor at a concentration of 0.5%, the powder is dried at a temperature of 80-110...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com