Vacuum pine oil-eliminating method and apparatus

A vacuum degreasing and pine wood technology, applied in the direction of pressure impregnation, etc., can solve the problems of shortened service life, wood cracking, and unclean removal of pine oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

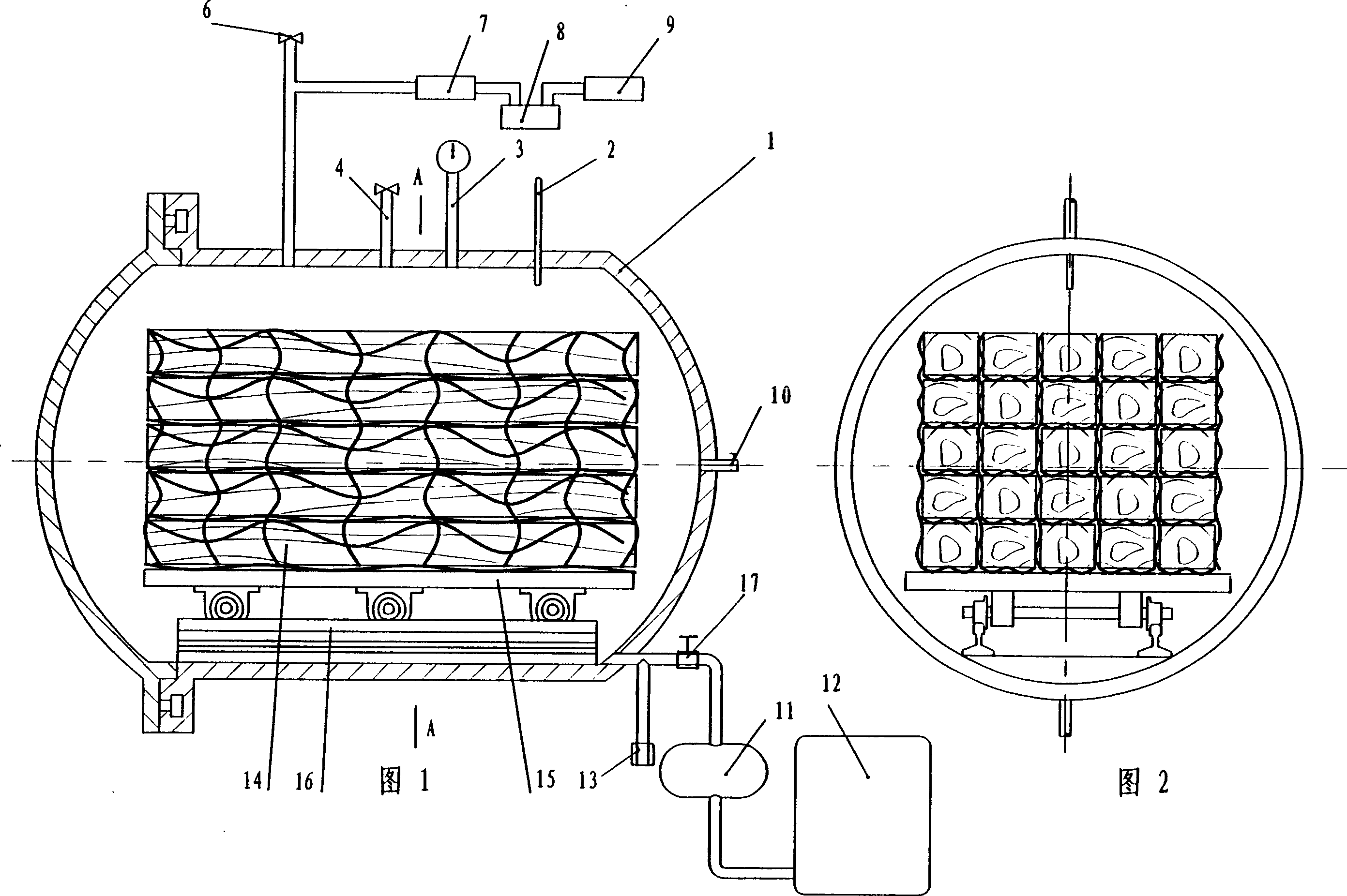

[0021] As seen from Fig. 1, 2, the vacuum degreasing method of pine of the present invention comprises the following steps:

[0022] 1) Wood stacking: place each piece of wood of the same thickness on the trolley alternately with metal chains, push it into the horizontal high-pressure tank along the guide rail, and the height of the wood must not exceed 80% of the height of the tank, and close the seal end caps and all valves;

[0023] 2) Inject degreaser: vacuumize the tank so that the pressure in the tank is 0.06-0.08MPa; turn on the degreaser switch, and the degreaser in the liquid storage tank will be automatically injected into the closed high-pressure tank. The degreaser should submerge the wood, space remains on it;

[0024] 3) High-temperature and high-pressure cooking: turn on the steam switch, input steam into the tank, heat the degreasing agent, make the temperature in the tank reach 100-120°C, and the pressure is 1.0-1.2MPa, cook wood, the thickness of a single pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com