Abstraction of pine nut oil, residual oil cake food after abstracting and its preparing method

A manufacturing method and technology of pine nut kernels, which are applied in the directions of food preparation, food science, application, etc., to achieve the effects of various product types, easy industrialization, and high oil extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

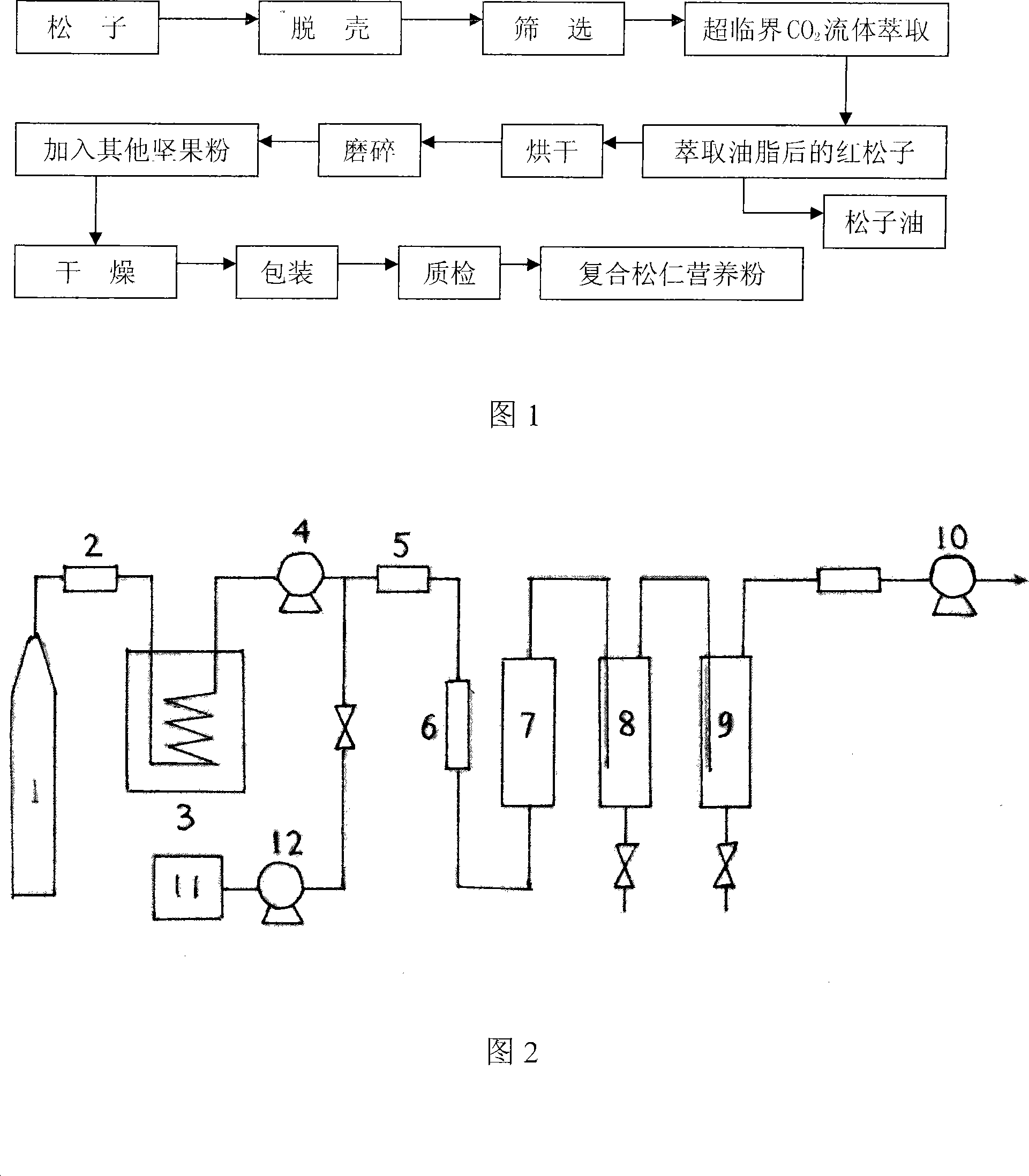

Method used

Image

Examples

example 1

[0029] Example 1 Supercritical CO of pine nut oil 2 Extraction preparation method implementation 1

[0030] Whole pine nuts are used as raw materials, and the oil residue after oil extraction will be used to process soft-packed instant pine nuts, so the extraction process is required to cause little damage to the appearance of pine nuts, just extract part of the oil and keep it in the raffinate of fat is used to enhance the flavor of ready-to-eat pine nuts.

[0031]Turn on the main power supply; start the refrigeration device, start the heating device of the extraction kettle and the separation kettle, the extraction kettle adopts 45°C, the separation I adopts 8MPa, 40°C; the separation II adopts 5MPa, 35°C. Whole pine nuts shelled from pine nuts are used as raw materials, anti-oxidant raw material ginger powder is added to the raw material of pine nuts, the addition amount is 1% of the weight of the pine nuts, and the addition amount of the synergist citric acid is 0.05% of ...

example 2

[0033] Example 2 Supercritical CO of pine nut oil 2 Extraction preparation method implementation 2

[0034] One-half to one-quarter crushed and mixed pine nuts are used as raw materials, and the oil residue after oil extraction will be used to process soft-packed instant pine nuts. Therefore, it is required that the extraction process has little damage to the appearance of pine nuts, and part of the oil is extracted. Yes, the oil that remains in the raffinate is used to enhance the flavor of the ready-to-eat pine nuts.

[0035] Turn on the main power supply; start the refrigeration device, start the heating device of the extraction kettle and the separation kettle, the extraction kettle adopts 48°C, the separation I adopts 8MPa, 42°C; the separation II adopts 5MPa, 33°C. With 1 / 2 broken pine nuts after shelling of pine nuts as raw material, the antioxidant raw material ginger powder is added to the raw material of pine nuts, the addition amount is 1.2% of the weight of the pi...

example 3

[0037] Example 3 Supercritical CO of pine nut oil 2 Extraction preparation method implementation 3

[0038] A quarter of broken pine nuts are used as raw materials, and the oil residue after oil extraction will be used to process soft-packed instant pine nuts. Therefore, it is required that the extraction process has little damage to the appearance of pine nuts, and only part of the oil can be extracted and retained in the raffinate The oil in the pine nuts is used to enhance the flavor of instant pine nuts.

[0039] Turn on the main power supply; start the refrigeration device, start the heating device of the extraction kettle and the separation kettle, the extraction kettle adopts 40°C, the separation I adopts 10MPa, 45°C; the separation II adopts 6MPa, 30°C. Use 1 / 4 broken pine nuts after shelling of pine nuts as raw material, add anti-oxidant raw material ginger powder to pine nuts raw material, the addition amount is 2.5% of the weight of pine nuts, and the addition amou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com