Flotation process for arsenic-containing pyrite

An arsenic pyrite and flotation technology, applied in flotation, solid separation and other directions, can solve the problems of heavy economic pressure on production enterprises and environmental hazards in the surrounding area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

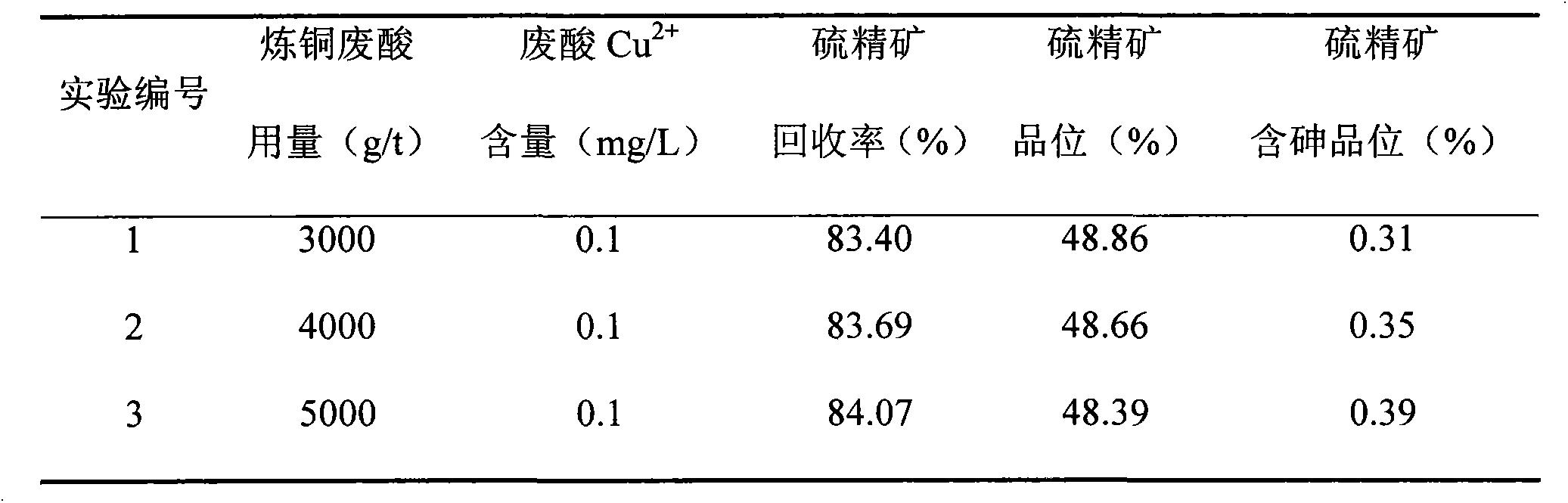

[0011] Select the ore containing 25.30% sulfur and 2.28% arsenic, grind the raw ore through a grinding machine until the monomers are dissociated, and then enter the flotation process, and add copper smelting waste acid (including Cu 2+ The content is 0.1mg / L), the dosage is 3000g / t, 4000g / t, 5000g / t respectively, as the activator of pyrite, adjust the pH value of the pulp to 6~7, and then add 500g of arsenopyrite inhibitor sodium humate / t, collector butyl xanthate 120g / t, pine oil 100g / t for pyrite flotation to obtain sulfur concentrate.

[0012] Table 1 Sulfur concentrate flotation indicators

[0013]

Embodiment 2

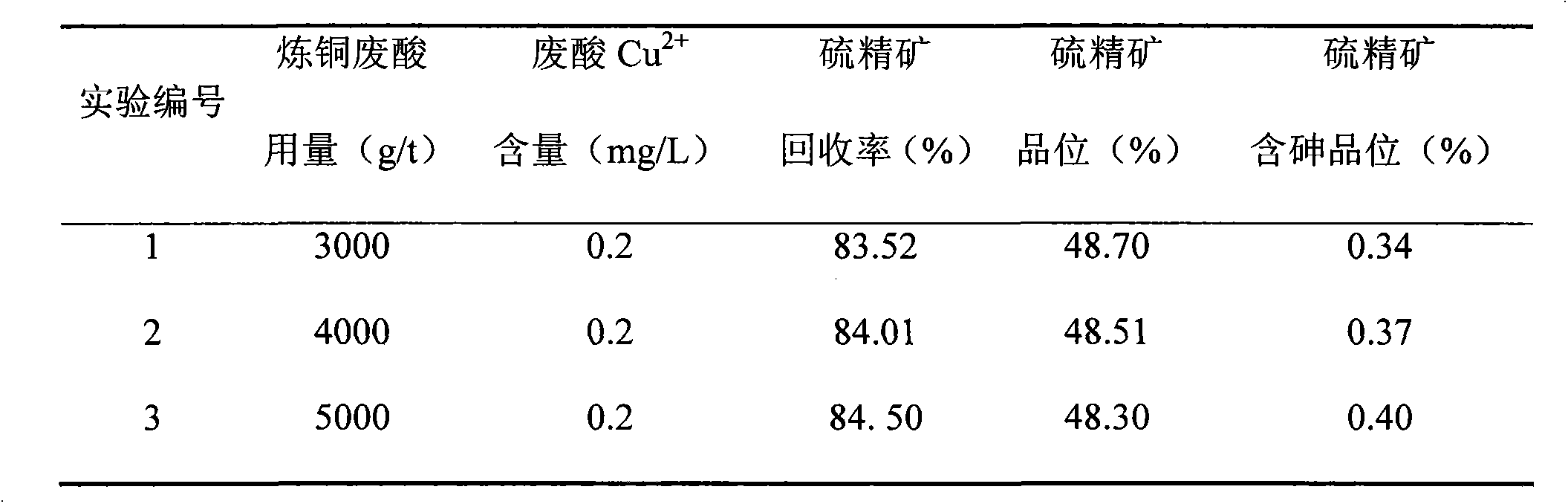

[0015] Select the ore containing 25.30% sulfur and 2.28% arsenic, grind the raw ore through a grinding machine until the monomers are dissociated, and then enter the flotation process, and add copper smelting waste acid (including Cu 2+ Content selection 0.2mg / L), the dosage is 3000g / t, 4000g / t, 5000g / t respectively, as the activator of pyrite, adjust the pH value of the pulp to 6~7, and then add 500g of arsenopyrite inhibitor sodium humate / t, collector butyl xanthate 120g / t, pine oil 100g / t for pyrite flotation to obtain sulfur concentrate.

[0016] Table flotation indicators of disulfide concentrate

[0017]

Embodiment 3

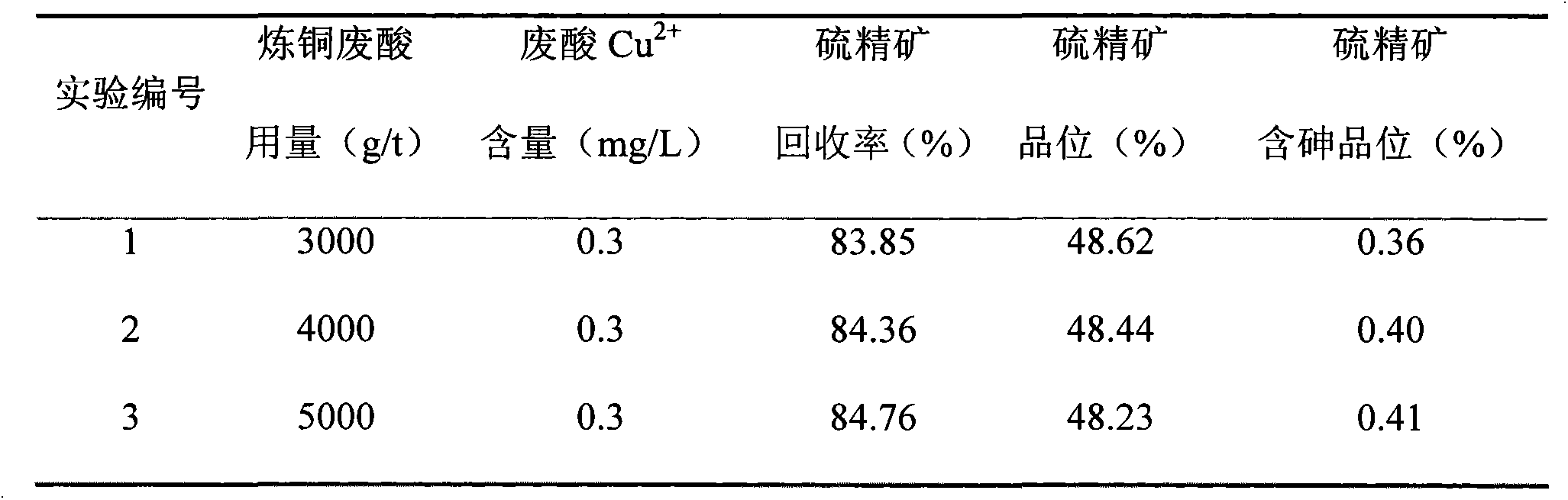

[0019] Select the ore containing 25.30% sulfur and 2.28% arsenic, grind the raw ore through a grinding machine until the monomers are dissociated, and then enter the flotation process, and add copper smelting waste acid (including Cu 2+ The content is 0.3mg / L), the dosage is 3000g / t, 4000g / t, 5000g / t respectively, as the activator of pyrite, adjust the pH value of the pulp to 6~7, and then add 500g of arsenopyrite inhibitor sodium humate / t, collector butyl xanthate 120g / t, pine oil 100g / t for pyrite flotation to obtain sulfur concentrate.

[0020] Table 3 Sulfur Concentrate Flotation Index Situation

[0021]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com