Non-curable rubber asphalt waterproof coating and preparation method and composite waterproof roll material thereof

A technology of asphalt waterproof coating and non-curing rubber, applied in asphalt coatings, fireproof coatings, lignin coatings, etc., can solve problems such as safety accidents, accelerate the greenhouse effect, and restrict the development of waterproof technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

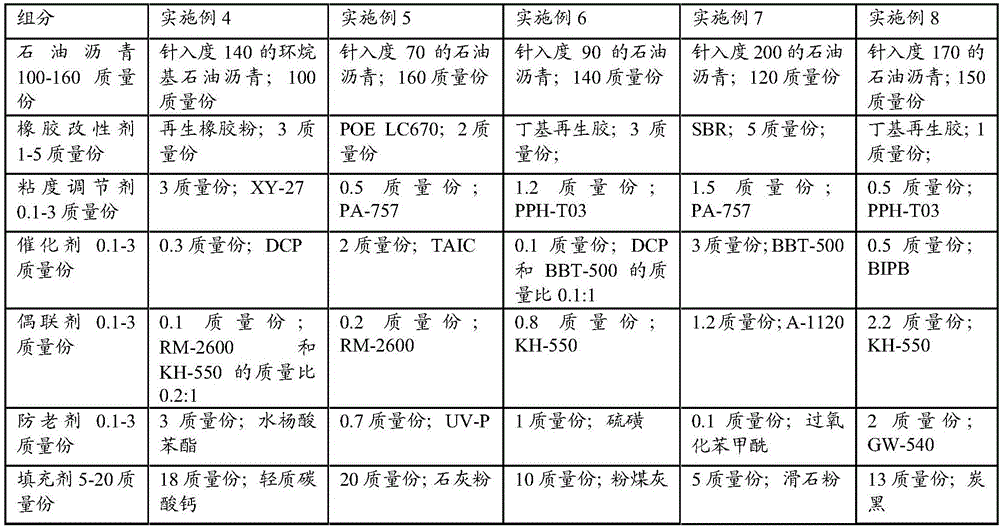

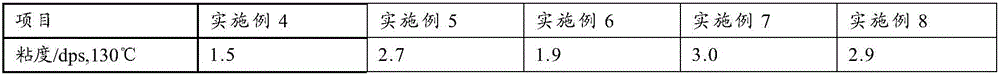

Embodiment 1

[0043] This embodiment provides a non-curing rubber asphalt waterproof coating, and its raw material formula includes: 100 parts by mass of petroleum asphalt; 3 parts by mass of rubber modifier; 3 parts by mass of viscosity modifier; 1.5 parts by mass of catalyst.

[0044] The petroleum pitch is a naphthenic petroleum pitch with a penetration of 70 (in 0.1mm); the rubber modifier is a polystyrene butadiene copolymer; the viscosity modifier is a sulfonated styrene cis- Butenedioic anhydride copolymer; the catalyst is TAIC.

[0045] The present embodiment provides a kind of preparation method of above-mentioned non-cured rubber asphalt waterproof coating, comprises the following steps:

[0046] Heat the petroleum asphalt in the mixing tank to 140°C, then add rubber modifier, swell at 165°C for 5 minutes (minutes), shear for 10 minutes, and swell for 20 minutes;

[0047] Add viscosity modifier, cut at 165°C for 15 minutes; add catalyst and coupling agent, cut at 165°C for 60 min...

Embodiment 2

[0053] This embodiment provides a non-curing rubber asphalt waterproof coating, and its raw material formula includes: 160 parts by mass of petroleum asphalt; 1 part by mass of rubber modifier; 1.5 parts by mass of viscosity modifier; 3 parts by mass of catalyst.

[0054] The petroleum asphalt is a naphthenic petroleum asphalt with a penetration of 120 (in 0.1mm); the rubber modifier is polystyrene butadiene copolymer and styrene-isoprene-styrene embedding segment copolymer (mass ratio is 2:1); the viscosity modifier is lignosulfonate; the catalyst is BBT-500.

[0055] The present embodiment provides a kind of preparation method of above-mentioned non-cured rubber asphalt waterproof coating, comprises the following steps:

[0056] Heat the petroleum asphalt in the mixing tank to 145°C, then add rubber modifier, swell at 170°C for 10 minutes, shear for 5 minutes, and swell for 25 minutes;

[0057] Add viscosity modifier, cut at 170°C for 20 minutes; add catalyst and coupling a...

Embodiment 3

[0059] This embodiment provides a non-curing rubber asphalt waterproof coating, and its raw material formula includes: 130 parts by mass of petroleum asphalt; 5 parts by mass of rubber modifier; 0.1 part by mass of viscosity modifier; 0.1 part by mass of catalyst.

[0060] The petroleum pitch is a naphthenic petroleum pitch with a penetration of 200 (in 0.1mm); the rubber modifier is a styrene-ethylene-butylene-styrene block copolymer; the viscosity modifier It is polypropylene resin and lignosulfonate (mass ratio 1:1); the catalyst is DCP.

[0061] The present embodiment provides a kind of preparation method of above-mentioned non-cured rubber asphalt waterproof coating, comprises the following steps:

[0062] Heat the petroleum asphalt in the mixing tank to 150°C, then add rubber modifier, swell at 160°C for 15 minutes, shear for 15 minutes, and swell for 15 minutes;

[0063] Add viscosity modifier, cut at 160°C for 25 minutes; add catalyst and coupling agent, cut at 160°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com