Magnesium oxide plate and manufacturing process thereof

A magnesia and board technology, applied in the field of boards, can solve the problems such as slightly poor waterproof performance of magnesia board, limited product wide application, poor fire and heat insulation performance, etc., so as to improve production efficiency, shorten molding time, and improve heat insulation effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

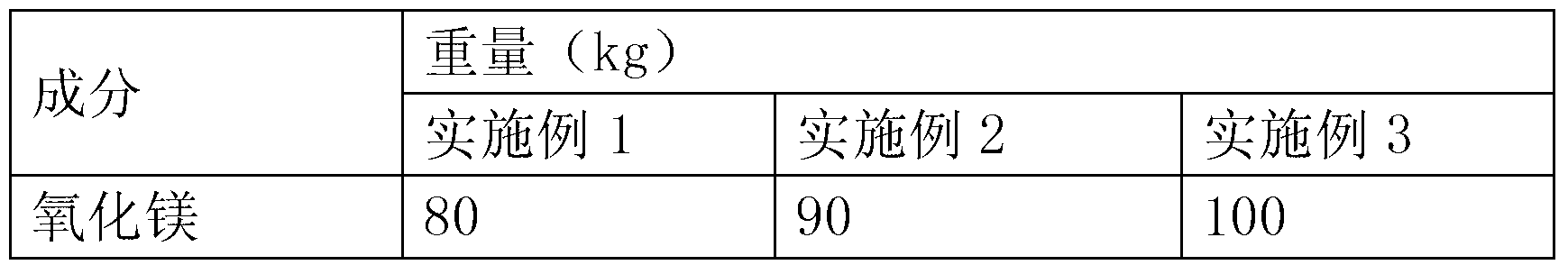

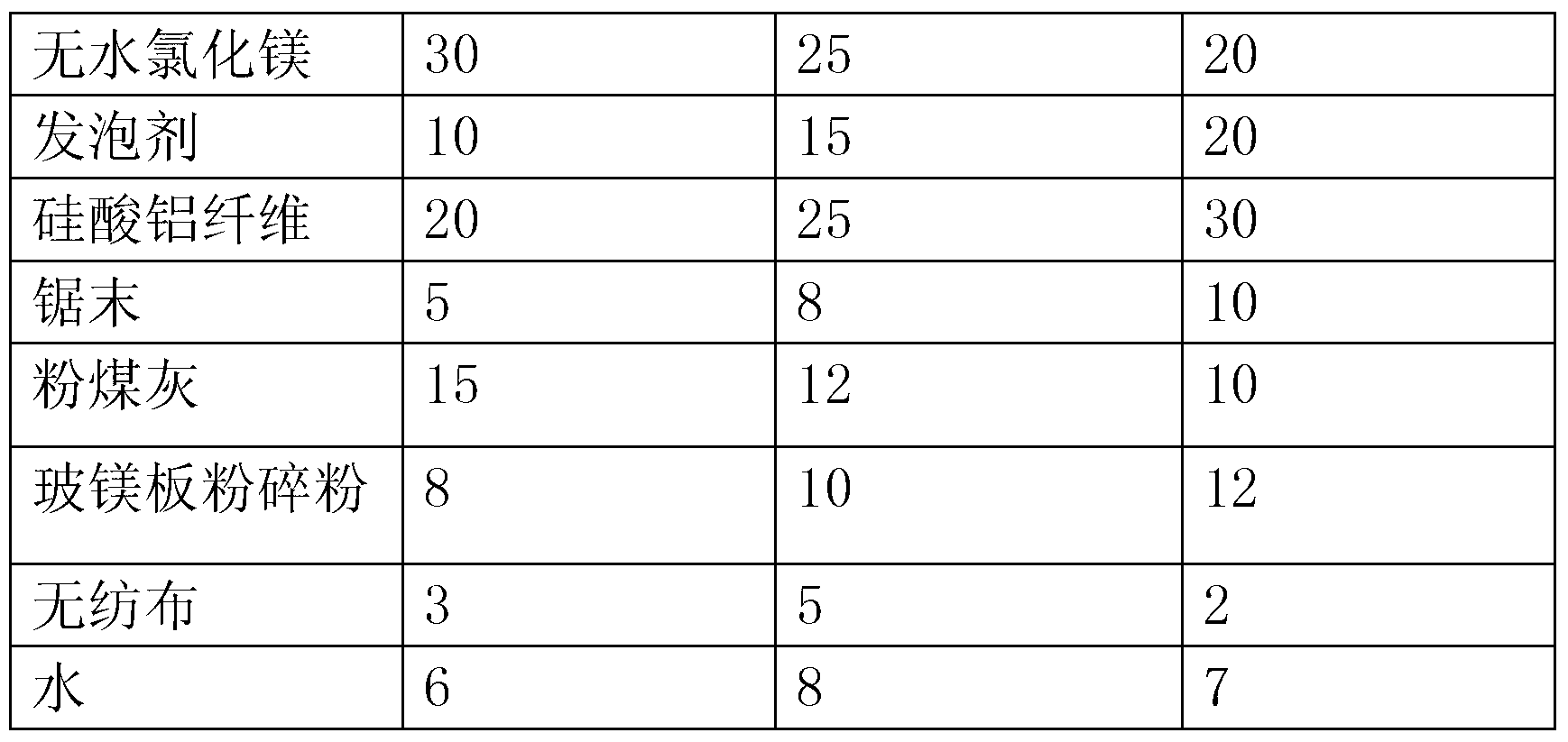

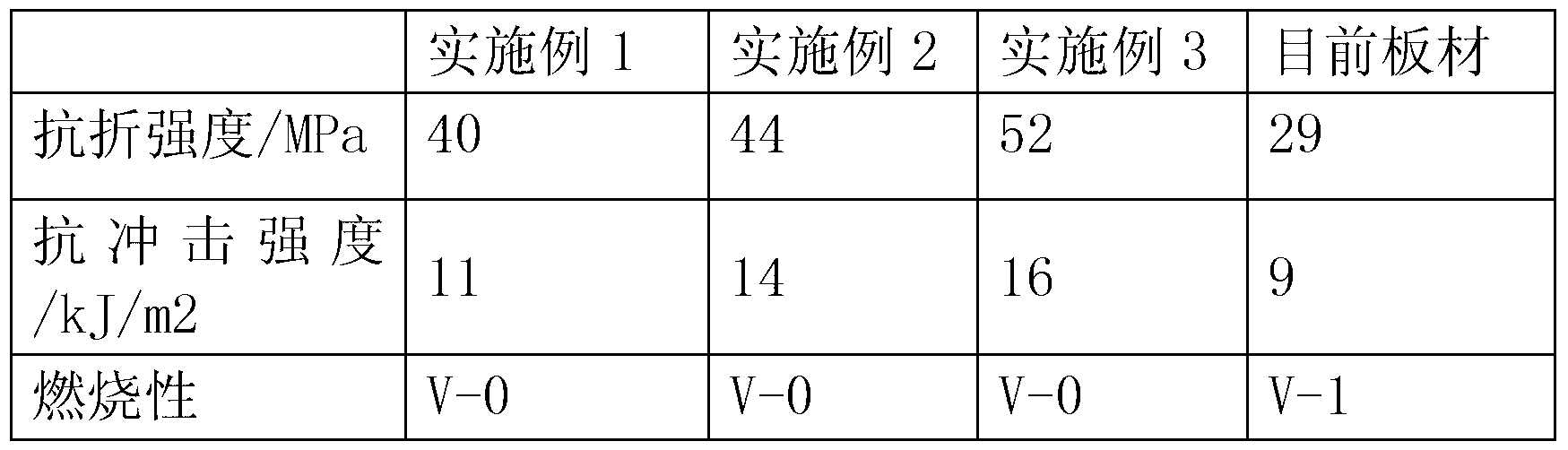

[0030] The present invention will be further described below in conjunction with the tables.

[0031]

[0032]

[0033] The weight of each composition of table 1 embodiment 1-3

[0034] Wherein, the foaming agent is a mixture of melamine, pentaerythritol and ammonium polyphosphate, and the mass ratio of melamine, pentaerythritol and ammonium polyphosphate is 4:2:1.

[0035] The manufacturing process of above-mentioned three embodiments, its steps are as follows:

[0036] (1), put magnesium oxide, anhydrous magnesium chloride, foaming agent, glass magnesium board pulverized powder into the mixer according to the weight of the magnesium oxide board described in claim 1, and simultaneously fill the mixer with gas to form bubbles, Stir for 15 minutes;

[0037] (2) Add aluminum silicate fiber, fly ash and sawdust into the mixer according to the weight of the magnesia board described in claim 1, continue stirring and mixing, and after uniform stirring for 30 minutes, make a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com