Fireproof plugging module

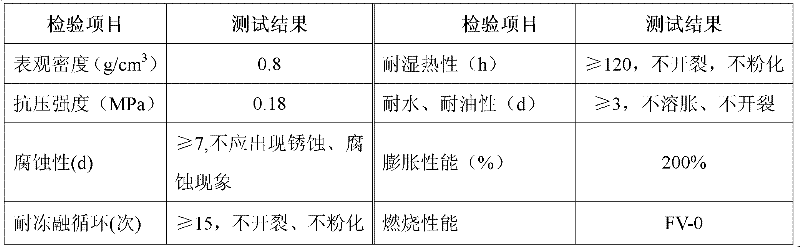

A technology of fire blocking and expanding vermiculite, applied in the field of blocking modules and fire blocking modules, can solve the problems of corrosion, inconvenient disassembly and poor plasticity of cables, and achieve the effects of long fire resistance time, lightening load and long validity period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Weigh the raw materials of each component according to the formula: 90 parts by weight of expanded vermiculite, 20 parts by weight of acrylic emulsion, 30 parts by weight of expanded graphite, and 5 parts by weight of zinc oxide; stir to make the above materials uniformly mixed; put the uniformly mixed materials into the mold Compression molding; the compressed molding module is naturally dried at room temperature, and after drying, it becomes the fireproof blocking module.

Embodiment 2

[0038] Weigh the raw materials of each component according to the formula: 80 parts by weight of expanded vermiculite, 30 parts by weight of acrylic emulsion, 20 parts by weight of expanded graphite, and 10 parts by weight of zinc oxide; stir to make the above materials uniformly mixed; put the uniformly mixed materials into the mold Compression molding; the compressed molding module is naturally dried at room temperature, and after drying, it becomes the fireproof blocking module.

Embodiment 3

[0040] Weigh the raw materials of each component according to the formula: 60 parts by weight of expanded vermiculite, 50 parts by weight of acrylic emulsion, 15 parts by weight of expanded graphite, and 20 parts by weight of zinc oxide; stir to make the above materials uniformly mixed; put the uniformly mixed materials into the mold Compression molding; the compressed molding module is naturally dried at room temperature, and after drying, it becomes the fireproof blocking module.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com