Wooden fireproof door and manufacturing process thereof

A manufacturing process and technology of fire doors, applied in the field of doors and windows, can solve problems such as affecting fire resistance and reliability, fire hinge failure, etc., and achieve the effects of flexible use, high safety, and long fire resistance time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

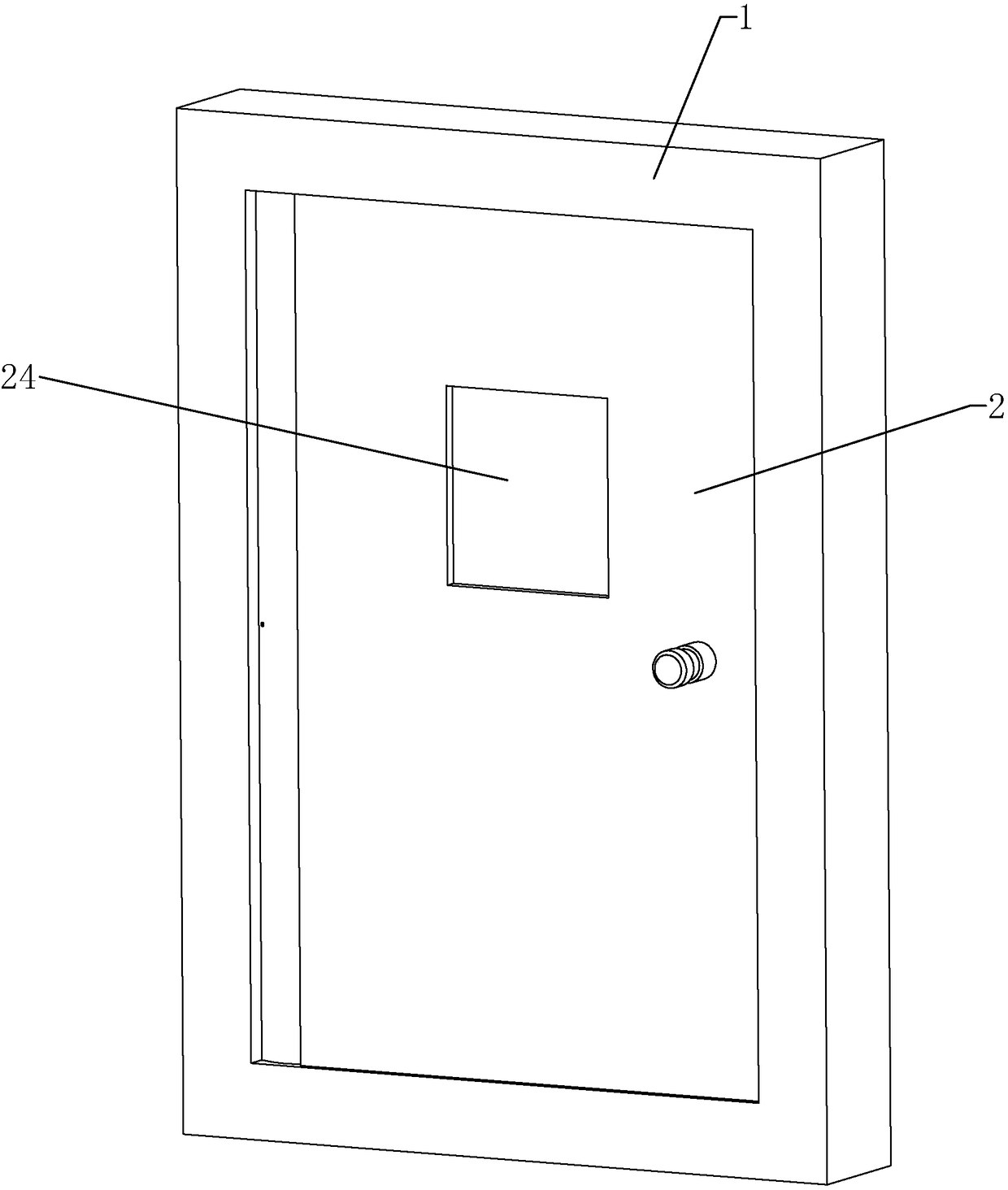

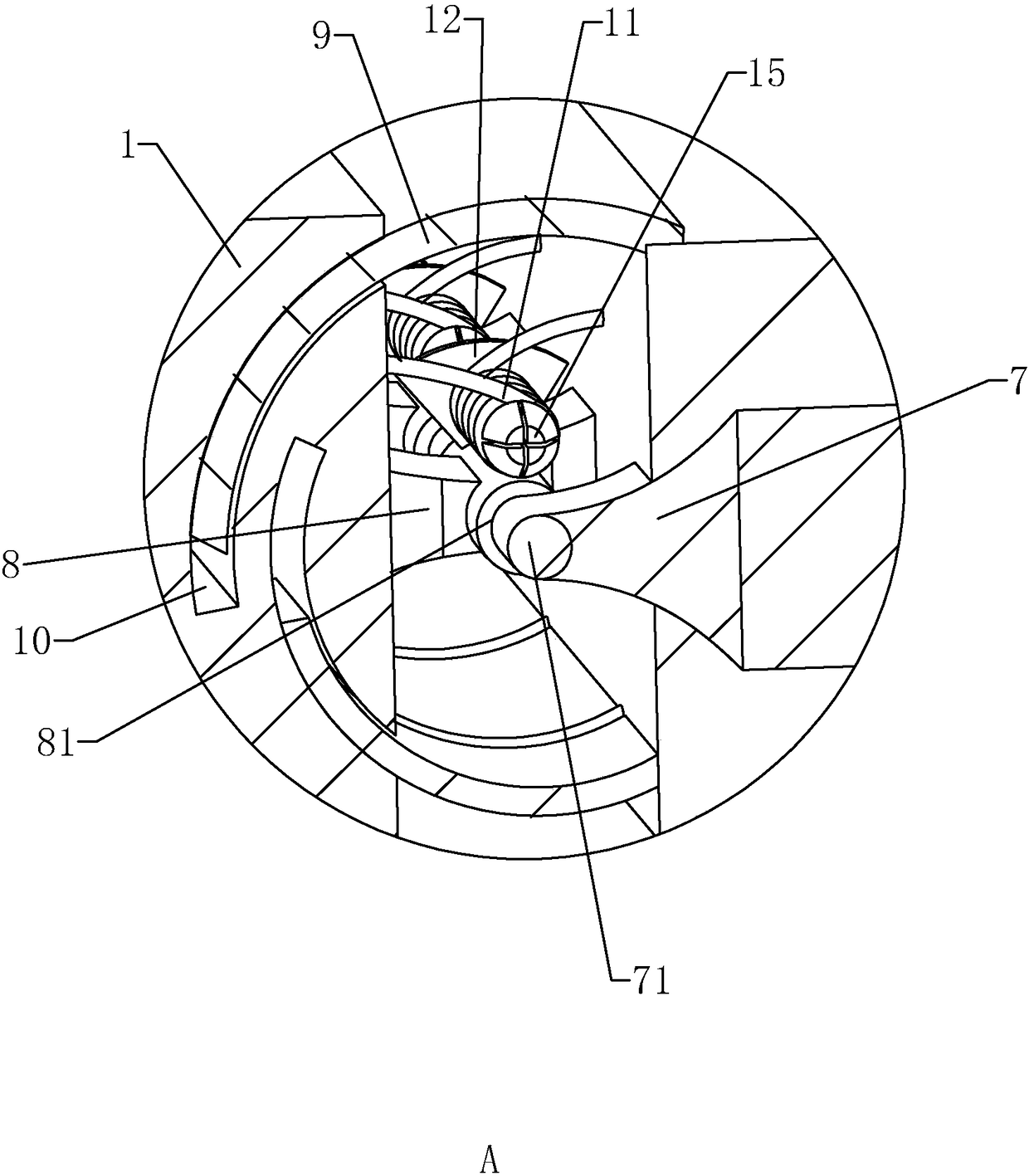

[0052] Embodiment 1: Reference figure 1 , a wooden fire door, comprising a door frame 1 and a door leaf 2, the door leaf 2 is rotatably connected to the door frame 1, and the door leaf 2 is opened and closed when the door leaf 2 rotates.

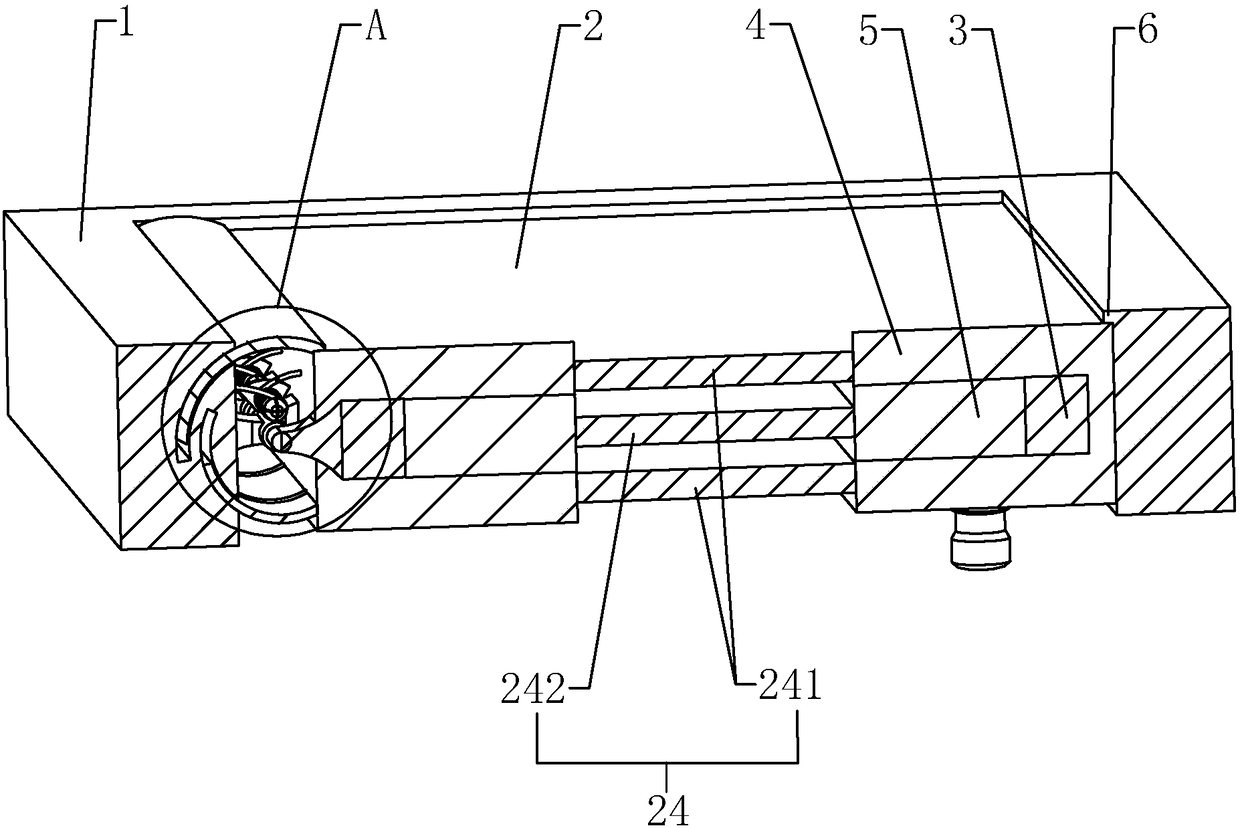

[0053] refer to figure 2 The door leaf 2 is provided with an observation window 24, which is used to observe the situation opposite the door leaf 2. When a fire occurs, the personnel on the other side of the door leaf 2 can observe the fire situation through the observation window 24, and then take corresponding measures according to the fire situation. rescue measures. The observation window 24 includes two fire-resistant glass plates 241 arranged at intervals, and a heat-insulating glass plate 242 is arranged between the two fire-resistant glass plates 241. The fire-resistant glass plate 241 has good fireproof performance, and is not easy to be exposed to high temperatures such as fire. Fragmentation, the insulating glass plate 242 has ...

Embodiment 2

[0063] Embodiment 2: A manufacturing process of a wooden fireproof door, including a door leaf manufacturing process and a door frame manufacturing process, wherein the door leaf manufacturing process includes the following steps:

[0064] Step 1. Drying the Chinese fir, controlling the moisture content to ≤15%, and removing the debris on the Chinese fir;

[0065] Step 2, carry out flame retardant treatment to the dried Chinese fir, inject a flame retardant, monitor the injection amount of the flame retardant, and take out the Chinese fir after the flame retardant injection reaches the standard;

[0066] Step 3, process the fir into the shape of the door panel, dry the door panel, and control the moisture content of the door panel to ≤12%;

[0067] Step 4. Weld the fan frame and weld the connecting plate on the fan frame, install and fix the door panel on the fan frame, and fill the fireproof and heat insulation layer into the door panel;

[0068] Step 5, edge sealing, polish...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com