Low-expansion heat-resisting fire-retardant glass

A fire-resistant glass, low-expansion technology, applied in the field of heat-resistant fire-resistant glass, can solve the problems of not being able to use the float process for one-time molding, low glass surface flatness, unable to meet fire protection requirements, etc., achieving light weight, small thermal expansion coefficient, blocking The effect of the spread of fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

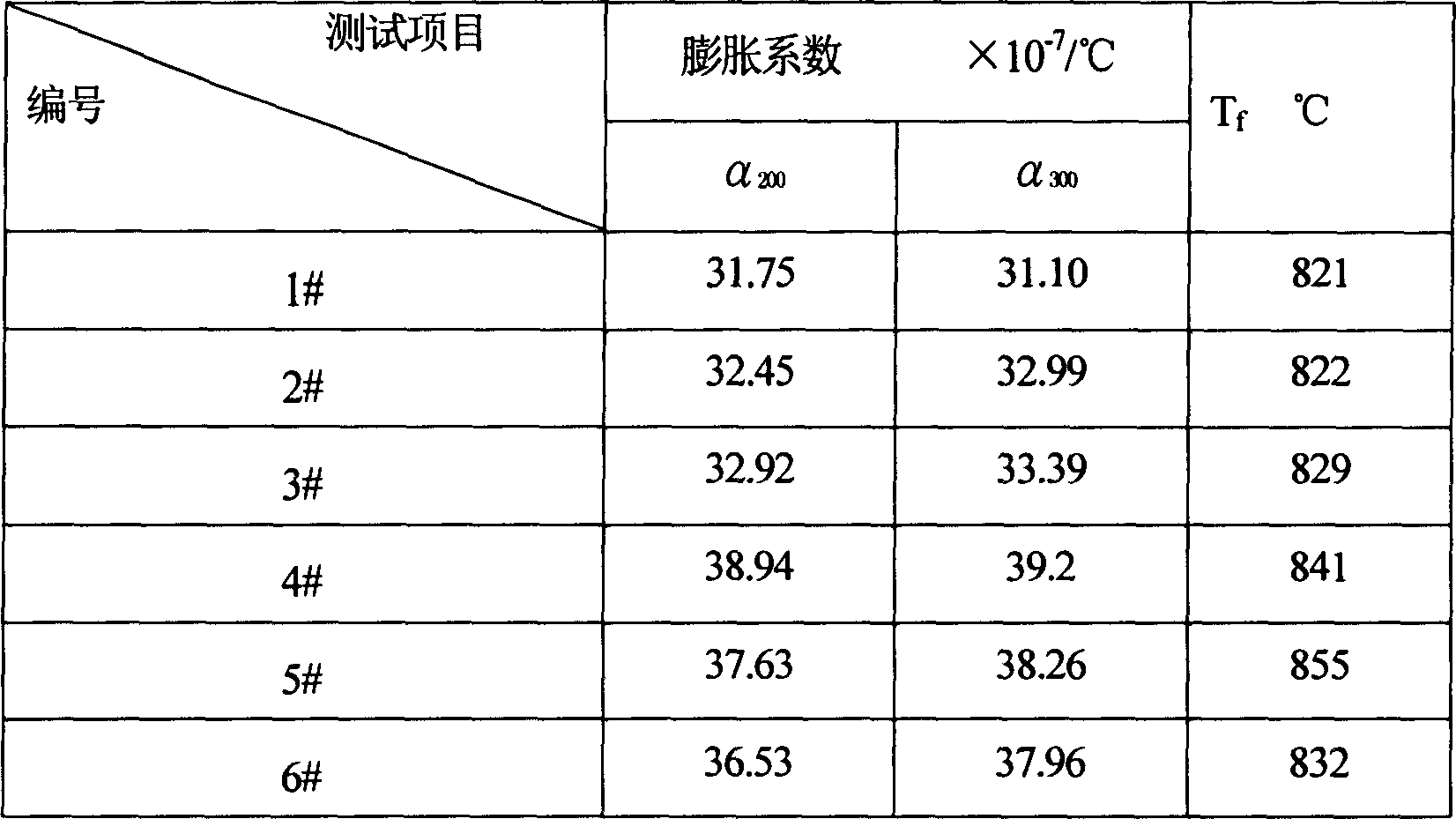

Embodiment 1

[0032] SiO 2 81%, B 2 o 3 12%, Al 2 o 3 1%, Na 2 O 2%, K 2 O 0.6%,

[0033] ZrO 2 0.4%, ZnO 0.1%, MgO 0.5% CaO 2%, the balance is impurities brought by mineral raw materials / clarifiers.

Embodiment 2

[0035] SiO 2 80%, B 2 o 3 11%, Al 2 o 3 1%, Na 2 O 3%, K 2 O 0.5%,

[0036] ZrO2 0.5%, ZnO 0.8%, MgO 1%, CaO 1.5%, and the balance is impurities brought by mineral raw materials / clarifiers.

Embodiment 3

[0038] SiO 2 75%, B 2 o 3 13%, Al 2 o 3 2%, Na 2 O 4%, K 2 O 1%,

[0039] ZrO 2 1%, ZnO 1.5%, MgO 0.5%, CaO 2%, and the balance is impurities brought by mineral raw materials / clarifiers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com