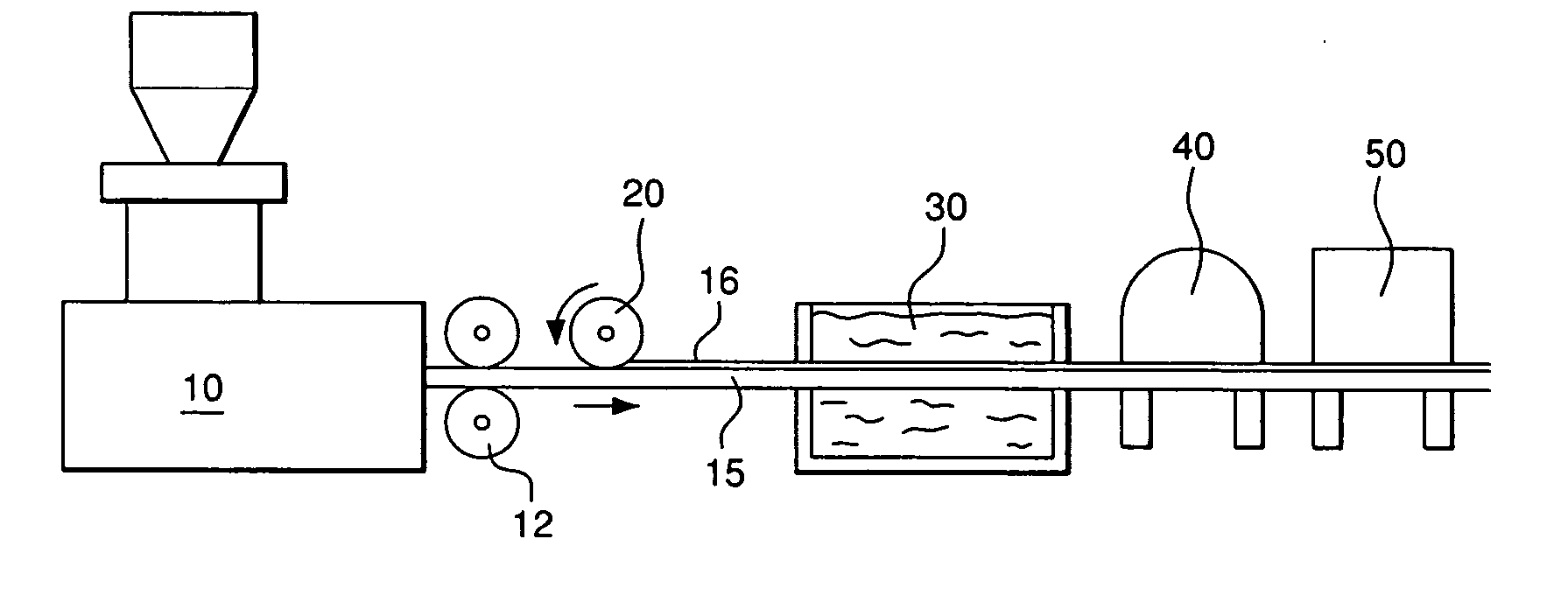

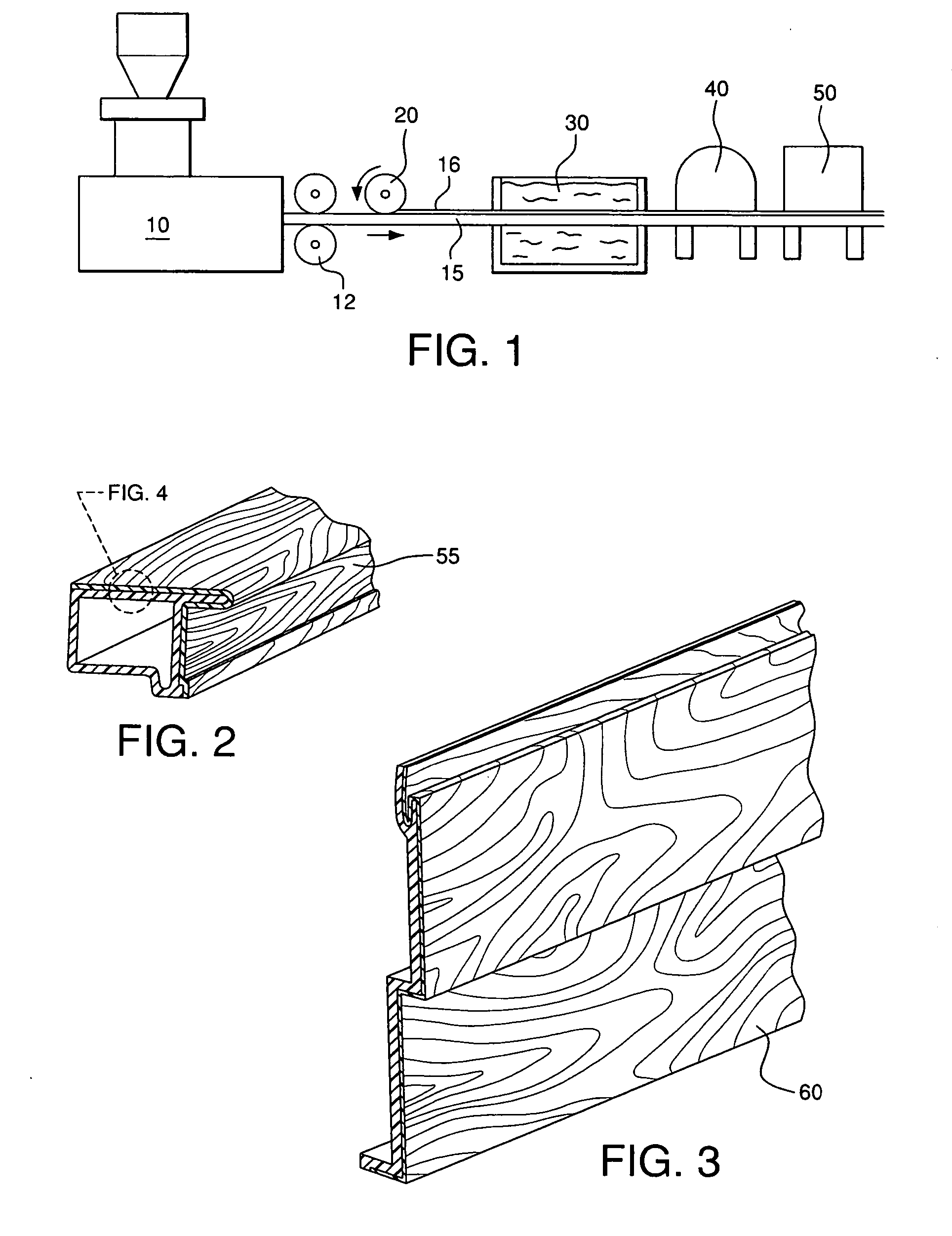

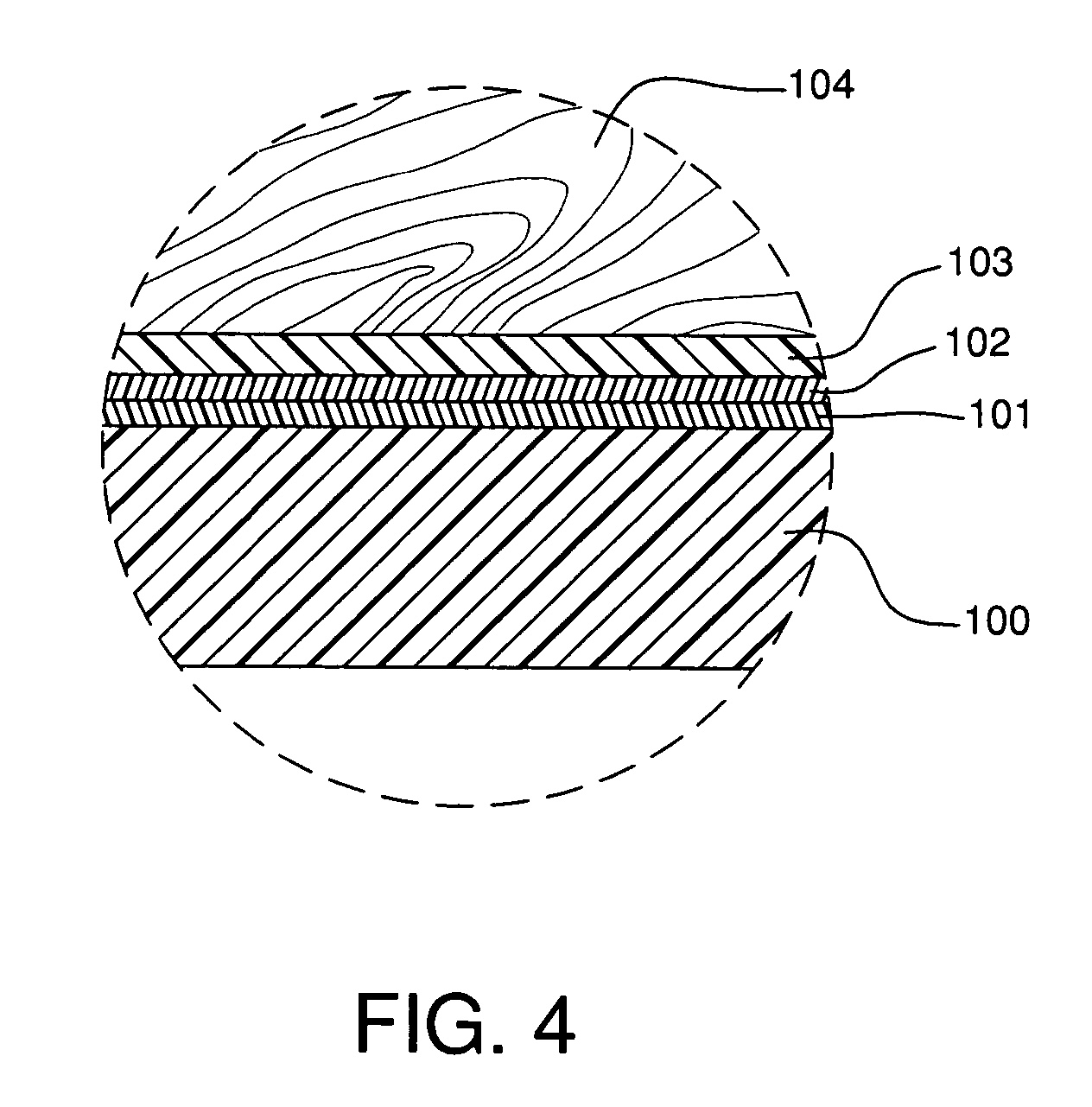

Building material having a fluorocarbon based capstock layer and process of manufacturing same with less dimensional distortion

a technology of fluorocarbon and building material, applied in the direction of girders, instruments, applications, etc., can solve the problems of few people achieving realistic wood-grain appearance, affecting the appearance of wood-grain surfaces, and dull vinyl siding colors. achieve the effect of realistic appearan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

[0044]

TABLE 1Working example of Liquid Cap-StockIngredientSupplierphr*Substrate CompositionsPVC ResinCertainTeed100Methyl tin StabilizerArkema1.0Lubricant 1, Ca StearateBaerlocher1.4Lubricant 2, PE WaxHoneywell0.2˜0.3Lubricant 3, Paraffin WaxHoneywell1.5Impact Modifier, AcrylicsRohm and Haas4.0Pigment, TiO2Kronos, DuPont0.8Filler, CaCO3Specialty Mineral10.0Capstock Selections1. Acrylonitrile-styrene-acrylateBASF100 (ASA) based copolymer2. PVC Cap-StockCertainTeed100

*phr = parts per hundred in reference to the PVC loading level

[0045]

TABLE 2PVC Cap-Stock CompositionIngredientSupplierphrPVC ResinCertainTeed100Methyl tin stabilizerCrompton(chemtura)1.2Lubricant 1, Ca StearateBaerlocher1.7Lubricant 2, PE WaxHoneywell0.2Lubricant 3, Paraffin WaxHoneywell0.2Processing aid, AcrylicsRohm and Haas0.5Impact Modifier, AcrylicsRohm and Haas4.0Paint Selections1. Polyvinylidene Fluoride (PVDF)2. Kynar based copolymerKalcor100

[0046]

TABLE 3Typical paint formulationwt.wetwt.vol.Add in order:gram...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com