Production technology of dried squid with beef flavor

A production process, dried squid technology, applied in the field of dried squid production technology, can solve the problems of environmental pollution, reduction of raw material utilization rate, high price, etc., to reduce environmental pollution, expand enterprise market share, increase taurine The effect of content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

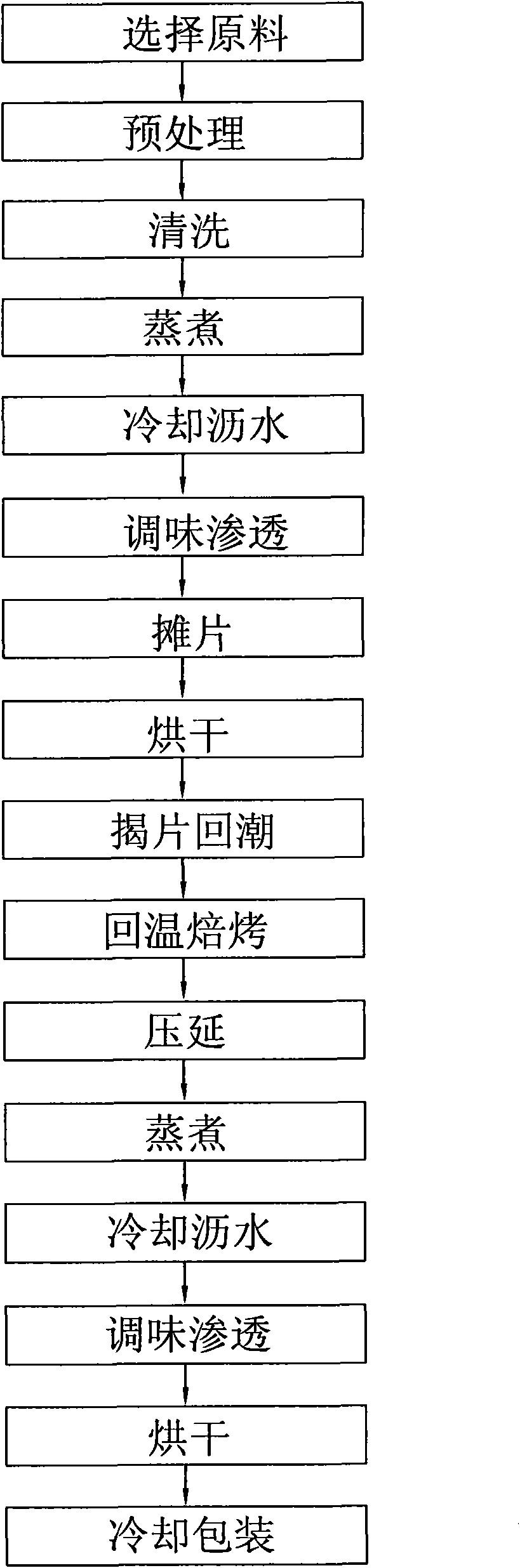

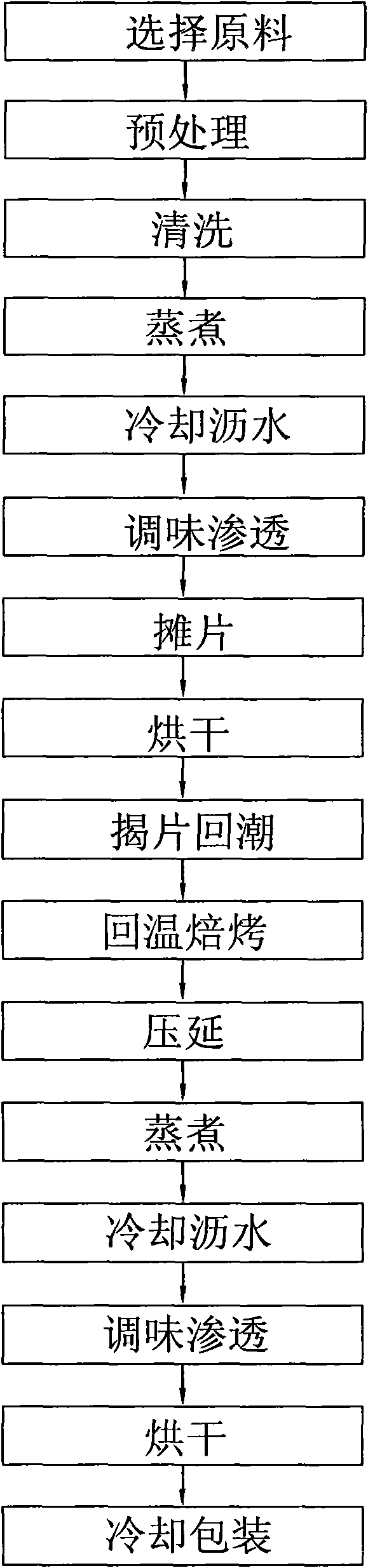

[0027] The present invention will be further described below with specific embodiment, see figure 1 :

[0028] The production technology of the dried squid with beef fragrance mainly comprises the following steps:

[0029] 1) Select raw materials: select squid scraps that are fresh, odorless, and with a specification of more than 500g as raw materials;

[0030] 2) Pretreatment: removing cartilage, skin and other appendages from the squid leftovers selected in step 1);

[0031] 3) Cleaning: wash off the residual impurities of the pretreated squid scraps with flowing water, and control the water temperature below 18°C;

[0032] 4) Cooking: steam the cleaned squid scraps according to their thickness and size, and control the cooking temperature at 96°C for 7-9 minutes, preferably freshly cooked;

[0033] 5) Cooling and draining: quickly put the cooked in-process product into ice water at 0°C for cooling. After cooling for half an hour, use a frame to drain the water. It is adv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com